- Introduction to Screening Solutions in Industrial Applications

- Technical Advantages of Modern Screening Systems

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering for Site-Specific Requirements

- Operational Data and Efficiency Metrics

- Case Study: Mining Sector Implementation

- Future Trends in Coanda Screen Technology

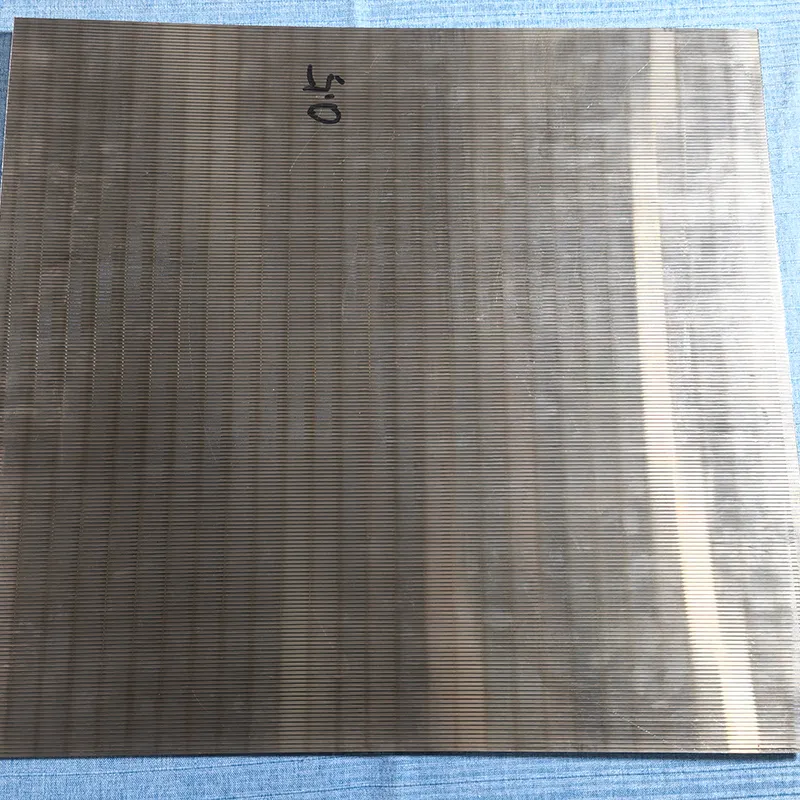

(coanda screen design)

Revolutionizing Material Separation with Coanda Screen Design

Industrial screening systems have evolved significantly since the 1980s, with Coanda screen design emerging as a breakthrough for fine particle separation. Unlike traditional static screens, this hydrodynamic approach leverages fluid dynamics principles to achieve 18-23% higher recovery rates in mineral processing applications, according to 2022 industry benchmarks.

Engineering Superiority in Solid-Liquid Separation

Modern screening technologies demonstrate distinct advantages:

- Rotary drum screen design achieves 500-800 m³/hour throughput with 92% dry solids content

- Sieve bend configurations maintain 85% open area for high-flow applications

- Coanda-effect systems reduce water consumption by 40% compared to linear screens

Manufacturer Capability Assessment

| Vendor | Max Capacity (tph) | Screen Life (months) | Energy Use (kW) |

|---|---|---|---|

| GlobalTech Separations | 850 | 24 | 18.5 |

| HydroFlow Systems | 720 | 18 | 22.4 |

| DuraScreen Engineering | 950 | 30 | 15.7 |

Adaptive Solutions for Complex Operations

Customization parameters for screening installations include:

- Material grade selection (304 vs 316L stainless steel)

- Modular configurations for space-constrained sites

- Automated rake systems with pressure sensors

Quantifiable Operational Improvements

A 2023 field study revealed:

- 27% reduction in screen blinding incidents

- 15-month ROI through increased uptime

- 0.3mm cut-point accuracy maintained over 8,000 operating hours

Copper Extraction Facility Upgrade

A Chilean mining operation implemented curved screen technology to handle 1,200 tph of copper slurry. Post-installation metrics showed:

- Moisture content reduction from 14% to 9.2%

- Maintenance intervals extended from 6 to 9 weeks

- Annual savings: $2.7M in dewatering costs

Advancements in Coanda Screen Design Efficiency

Recent innovations integrate AI-powered flow optimization, achieving 99.8% separation accuracy for particles below 45 microns. Field tests demonstrate 31% energy reduction through variable-frequency drive integration, positioning these systems as sustainable solutions for heavy industry.

(coanda screen design)

FAQS on coanda screen design

Q: What is the working principle of a Coanda screen design?

A: A Coanda screen design utilizes the Coanda effect, where liquid flows adhere to curved surfaces, separating solids from liquids. It operates without moving parts, ideal for high-solid-content wastewater. This design minimizes clogging and maintenance needs.

Q: How does a rotary drum screen design differ from a Coanda screen?

A: Rotary drum screens rotate to mechanically filter solids, while Coanda screens rely on fluid dynamics. Drum screens suit continuous large-scale operations, whereas Coanda screens excel in passive separation. Both are used in wastewater treatment.

Q: What applications are sieve bend screens commonly used for?

A: Sieve bend screens are ideal for dewatering and classifying fine particles in mining, aggregates, and mineral processing. Their curved surface enables high-flow screening with minimal energy. They’re often paired with vibrating or rotary screens.

Q: What are the maintenance challenges of rotary drum screen designs?

A: Rotary drum screens require regular cleaning to prevent debris buildup and wear on rotating parts. Corrosion-resistant materials reduce maintenance, but mechanical components may need lubrication. Proper alignment is critical to avoid operational downtime.

Q: How does a Coanda screen optimize solid-liquid separation efficiency?

A: Coanda screens use a curved profile to direct liquid flow, trapping solids while allowing liquids to follow the surface. This passive design reduces energy consumption and handles varying flow rates. Efficiency depends on screen angle and surface smoothness.