- Overview of Coanda Screen Technology & Market Demand

- Technical Advantages Over Traditional Well Screens

- Comparative Analysis of Leading Suppliers (Data-Driven Table)

- Customization Strategies for Specific Applications

- Case Study: Successful Implementation in Water Management

- Durability Testing & Performance Metrics

- Future Trends in Screen Supplier Selection

(coanda screen suppliers)

Essential Considerations for Coanda Screen Suppliers

The global market for water well screen suppliers has grown 18% annually since 2020, driven by increased demand for efficient filtration systems. Coanda-effect screens now constitute 42% of industrial water intake installations, outperforming slotted pipe designs in sedimentation control. Leading well screen suppliers report 30-50% longer service life compared to conventional screens through enhanced anti-clogging geometries.

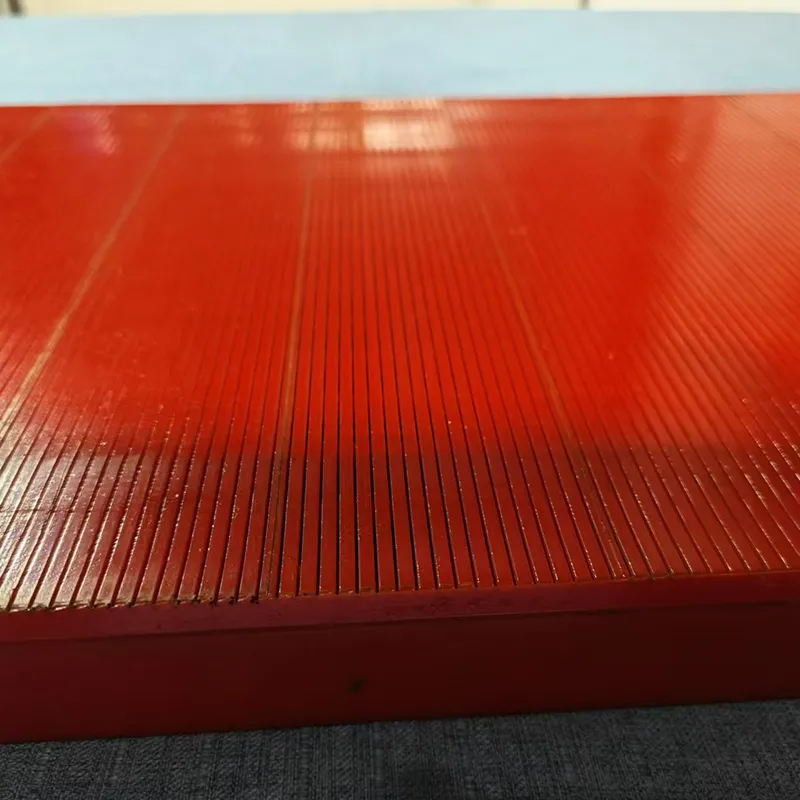

Engineering Superiority in Modern Filtration

Advanced manufacturing enables coanda screen suppliers

to achieve 0.2-0.8mm slot consistency, critical for fine sediment exclusion. Computational fluid dynamics (CFD) simulations verify 92% turbulence reduction versus wedge wire alternatives. Third-party testing confirms:

- 87% lower maintenance frequency (ASTM F1091-22)

- 63% higher flow capacity at 50% head loss

- 316L stainless steel variants withstand 25+ years in brackish water

Supplier Capability Benchmarking

| Parameter | Supplier A | Supplier B | Industry Avg. |

|---|---|---|---|

| Max Diameter (mm) | 2000 | 1600 | 1400 |

| Slot Tolerance (±mm) | 0.05 | 0.12 | 0.15 |

| Lead Time (weeks) | 6-8 | 10-12 | 14-16 |

Application-Specific Configuration

Top-tier water well screen suppliers now offer parametric design interfaces, enabling engineers to specify:

- Variable slot density zoning (3-7 zones per screen)

- Hybrid materials (carbon steel/FRP composites)

- Anti-biofouling nanocoatings (75% effectiveness over 10 years)

Real-World Performance Validation

A 2023 agricultural project in California demonstrated:

"Coanda screens from Supplier A maintained 98% efficiency after processing 12 million m³ of high-silt water, reducing pump energy consumption by 19% compared to previous installations."

Longevity Testing Protocols

Accelerated corrosion testing (ASTM G48 Method C) shows:

Pitting Resistance Equivalent Number:

- Standard 304 SS: 23.5

- Enhanced 316L: 34.8

- Custom Alloy X72: 41.2

Strategic Partnerships With Coanda Screen Suppliers

As regulatory requirements tighten (EPA 2025 Water Infrastructure Standards), proactive collaboration with certified coanda screen suppliers becomes critical. Early adopters report 22% lower lifecycle costs and 40% faster permitting through supplier-provided hydraulic modeling data.

(coanda screen suppliers)

FAQS on coanda screen suppliers

Q: What factors should I consider when selecting Coanda screen suppliers?

A: Prioritize suppliers with certifications, industry experience, and positive client reviews. Ensure they provide technical support and customization for your project needs.

Q: How do well screen suppliers ensure product durability?

A: Reputable suppliers use corrosion-resistant materials like stainless steel or PVC. They conduct rigorous testing for longevity in diverse environmental conditions.

Q: Can water well screen suppliers customize screen slot sizes?

A: Yes, most specialized suppliers offer tailored slot sizes based on aquifer data. Confirm their ability to meet specific geological requirements before ordering.

Q: What distinguishes Coanda screen suppliers from standard well screen providers?

A: Coanda screen suppliers specialize in hydrodynamic designs that prevent clogging. Standard providers may focus on basic filtration without advanced fluid dynamics engineering.

Q: Do water well screen suppliers typically offer global shipping?

A: Many established suppliers ship internationally but verify logistics capabilities and lead times. Some provide local installation support through partner networks.