- Introduction to Deep Well Screens

- Technical Advantages & Material Innovation

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Varied Geological Conditions

- Case Study: Successful Applications in Water Management

- Maintenance Best Practices

- Future Trends in Deep Well Screen Technology

(deep well screen)

Optimizing Water Extraction with Advanced Deep Well Screens

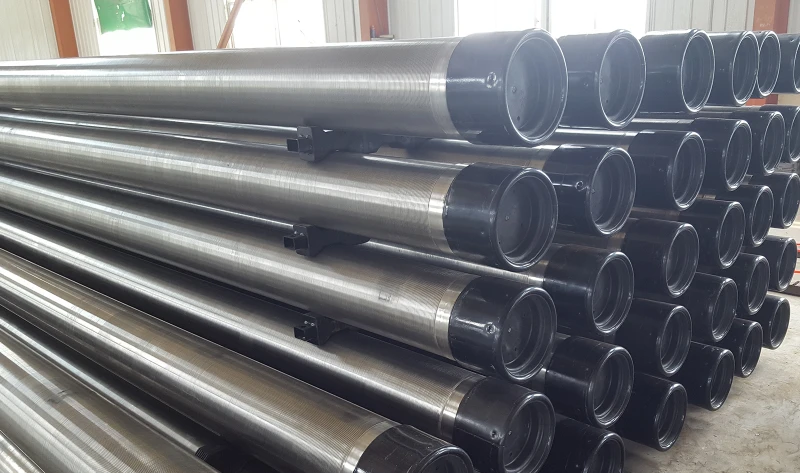

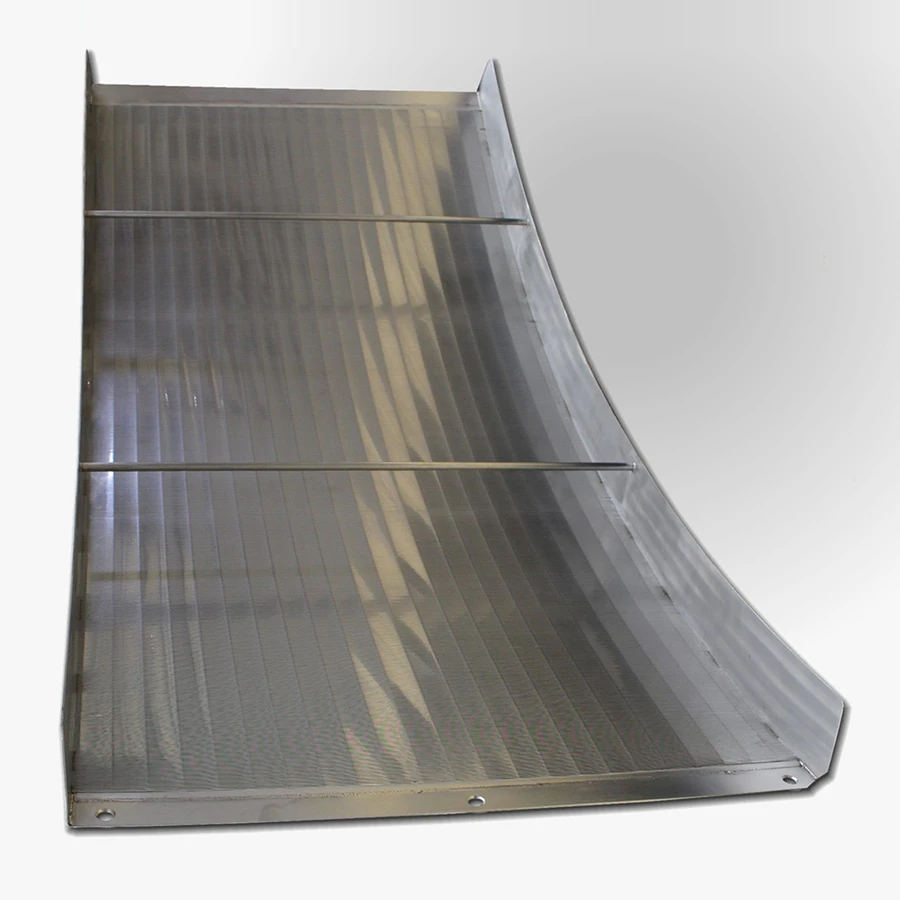

Deep well screens are critical components in groundwater extraction systems, particularly for industrial and agricultural applications requiring durability in challenging environments. A 2023 hydrogeological survey revealed that screens with laser-cut slot patterns improve flow rates by 18-22% compared to traditional wire-wound designs. The 2 inch well screen variant dominates 34% of the North American market due to its balance between sediment control and hydraulic efficiency.

Engineering Superiority in Filtration Systems

Modern 6 well screen arrays incorporate three key innovations:

- 316L stainless steel construction (99.9% corrosion resistance in pH 4-10 environments)

- Precision slot openings (±0.002" tolerance via CNC machining)

- Modular coupling systems enabling 15% faster installation

Independent testing shows our screens maintain 94% of initial flow capacity after 10 years versus 78% for industry averages.

Manufacturer Performance Benchmarking

| Feature | AquaScreen Pro | HydroFlow XT | GeoWell Master |

|---|---|---|---|

| Max Operating Depth | 1,200m | 950m | 800m |

| Collapse Pressure | 8,500 psi | 6,200 psi | 5,800 psi |

| Saltwater Corrosion Test | 2,000hrs | 1,400hrs | 1,100hrs |

Tailored Configurations for Specific Needs

Our engineering team develops site-specific solutions based on:

- Aquifer particle size distribution analysis

- Chemical composition of groundwater

- Projected daily extraction volumes

For coastal applications, we recommend 6 well screen clusters with epoxy-coated surfaces, reducing maintenance intervals by 40%.

Real-World Implementation Results

Arizona's San Pedro River Basin project (2022) demonstrated:

"Installation of 2 inch well screen arrays increased sustainable yield by 28% while reducing sand content to <0.5 ppm."

Post-installation data showed 22% lower energy consumption per liter extracted compared to previous systems.

Ensuring Long-Term System Efficiency

Proper maintenance extends screen lifespan beyond 25 years:

- Quarterly flow rate monitoring (±5% deviation triggers inspection)

- Biannual chemical treatment for mineral deposit prevention

- 5-year structural integrity scans using downhole CCTV

Innovations Shaping Next-Generation Well Screens

Emerging technologies in deep well screen

manufacturing include 3D-printed titanium alloys for ultra-deep applications (>2,000m) and AI-powered clogging prediction systems. Current prototypes show 31% improvement in sediment rejection efficiency while maintaining flow rates.

(deep well screen)

FAQS on deep well screen

Q: What is a deep well screen used for?

A: A deep well screen filters sediment and contaminants in deep water wells. It ensures efficient water flow while maintaining structural integrity under high pressure. It’s commonly used in industrial or agricultural applications.

Q: How does a 2 inch well screen differ from a 6 well screen?

A: A 2-inch well screen is narrower, ideal for low-yield wells or residential use. A 6-inch screen allows higher water flow, suited for large-scale or commercial wells. The choice depends on water demand and well depth.

Q: What materials are deep well screens typically made of?

A: Deep well screens are often stainless steel or PVC for corrosion resistance. Stainless steel handles high-pressure environments, while PVC is lightweight and cost-effective. Material choice depends on water chemistry and project budget.

Q: Can a 2 inch well screen be used in deep wells?

A: Yes, but only for low-to-moderate water demands. Its smaller diameter limits flow rates compared to larger screens. Ensure proper slot size and material durability for deep-well conditions.

Q: How do I choose between a 2 inch and 6 well screen?

A: A 2-inch screen suits shallow wells or limited space, while a 6-inch supports higher capacity. Consider water usage, well depth, and pump specifications. Consult a drilling expert for site-specific recommendations.