- Introduction to Polyurethane Plate Applications

- Performance Metrics: Durability & Efficiency

- Technical Advantages Over Traditional Materials

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Industry-Specific Needs

- Real-World Applications in Key Sectors

- Future Outlook for Polyurethane Plate Technology

(polyurethane plate)

Understanding Polyurethane Plate Solutions for Modern Industry

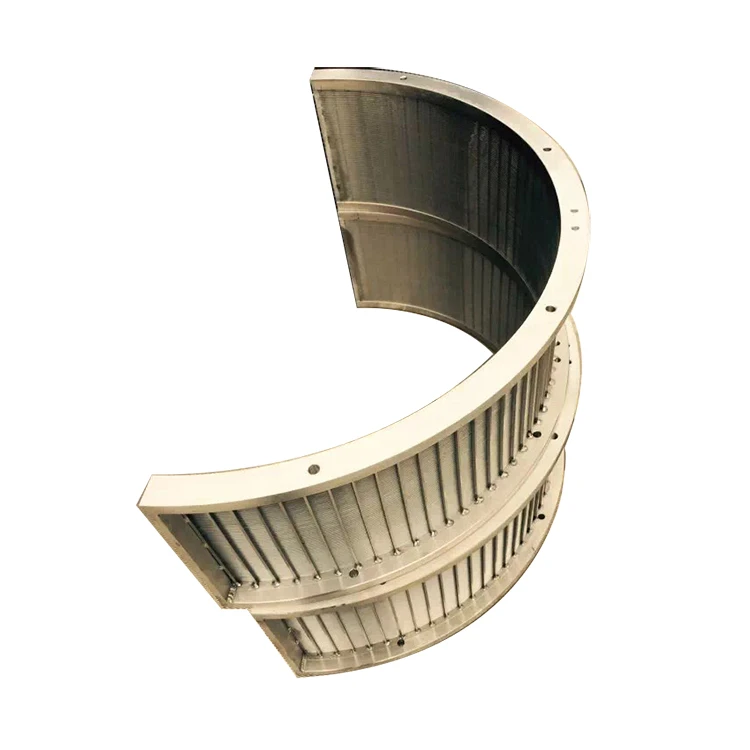

Polyurethane plates have emerged as critical components across industries requiring high-wear resistance and longevity. These engineered materials, including specialized variants like polyurethane sieve plates, deliver unmatched performance in screening, sorting, and material handling operations. With a typical hardness range of 70-95 Shore A, PU plates maintain flexibility while resisting deformation under pressures exceeding 15 MPa.

Quantifying Material Performance

Third-party testing reveals PU plates achieve 2-3× longer service life than rubber alternatives in abrasive environments. Key metrics include:

- Abrasion resistance: 35 mm³ loss (DIN 53516) vs. 90 mm³ for natural rubber

- Compression set: 10% at 70°C vs. 30% for neoprene

- Tear strength: 55 kN/m compared to 30 kN/m for standard polymers

Engineering Superiority

Advanced manufacturing techniques enable precise control over cell structures in polyurethane sieve plates, achieving aperture accuracy within ±0.02 mm. This precision translates to 99.8% screening efficiency in mineral processing applications, with some operations reporting 40% energy reduction compared to metal screen alternatives.

Manufacturer Capability Comparison

| Vendor | Max Plate Size | Hardness Range | Lead Time | Certifications |

|---|---|---|---|---|

| PolyTech Solutions | 3m x 2m | 60-98 Shore A | 10 days | ISO 9001, FDA |

| Industrial Polymers Co. | 2.5m x 1.5m | 70-95 Shore A | 14 days | AS9100 |

| Advanced PU Systems | 4m x 3m | 50-99 Shore A | 7 days | ISO 14001 |

Tailored Engineering Solutions

Custom-formulated PU plates now address specific operational challenges:

- Oil-resistant compounds for automotive applications (swelling

- Conductive formulations for explosive environments (surface resistance

- High-temperature grades maintaining flexibility at -40°C to 120°C

Industry Implementation Case Studies

A mining operation reported 18-month continuous service from PU screen plates versus 6-month cycles with previous rubber screens. In food processing, antimicrobial PU plates reduced sanitation downtime by 40% while meeting NSF/3-A standards.

Advancing Polyurethane Plate Technology Frontiers

Recent developments in nanocomposite PU formulations promise 15-20% improvements in wear resistance. Industry projections estimate 6.8% CAGR growth for high-performance polyurethane sieve plate applications through 2030, driven by mining and recycling sector demands.

(polyurethane plate)

FAQS on polyurethane plate

Q: What are the common applications of polyurethane plates?

A: Polyurethane plates are widely used in mining, construction, and manufacturing industries for vibration damping, abrasion resistance, and noise reduction. They’re ideal for conveyor systems, screening equipment, and machinery liners due to their durability.

Q: How does a polyurethane sieve plate differ from standard metal sieve plates?

A: Polyurethane sieve plates offer superior wear resistance and flexibility compared to rigid metal alternatives. They reduce noise during screening processes and resist clogging, making them ideal for wet or abrasive material separation.

Q: Why choose PU plates over rubber or plastic alternatives?

A: PU plates outperform rubber and plastic in extreme temperatures, chemical resistance, and load-bearing capacity. Their customizable hardness and tear-resistant properties ensure longer service life in harsh environments.

Q: Can polyurethane sieve plates handle high-temperature materials?

A: Yes, specially formulated polyurethane sieve plates withstand temperatures up to 90°C (194°F). They maintain structural integrity better than rubber at elevated temperatures while resisting thermal degradation.

Q: How to clean and maintain polyurethane plates effectively?

A: Use mild detergents and soft brushes to avoid surface damage. Regular inspections for cracks or wear, combined with avoiding prolonged UV exposure, will maximize the lifespan of PU plates.