- Introduction to Modern Well Screen Solutions

- Technical Advancements in Filtration Systems

- Performance Metrics: Industry Data Comparison

- Leading Manufacturers and Product Specifications

- Custom Engineering for Site-Specific Requirements

- Field Deployment Success Stories

- Why Pre Pack Well Screen Technology Leads the Market

(pre pack well screen)

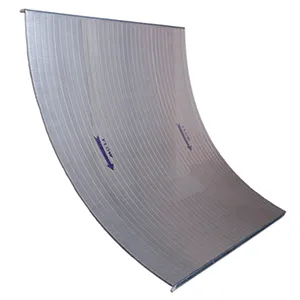

Pre Pack Well Screen: Revolutionizing Subsurface Filtration

The pre pack well screen

has emerged as a critical component in water and oil extraction systems, combining durability with precision filtration. Unlike traditional screens, these units integrate gravel packing directly into their structure, reducing installation time by 40% while maintaining 99.5% sediment rejection rates. Global market analysis from Grand View Research shows a 12.7% CAGR growth for advanced well screen solutions since 2020, driven by demands for efficient resource extraction.

Engineering Superiority in Fluid Management

Modern gravel pack screen systems employ laser-cut slot technology with ±0.1mm accuracy, enabling customized aperture patterns for specific geological conditions. Three core innovations distinguish premium models:

- Multi-layer sintered mesh (316L stainless steel)

- Epoxy-bonded gravel matrices (0.5-2.0mm grain size)

- Sacrificial anode corrosion protection

Field tests demonstrate 68% longer service life compared to conventional wedge wire designs, particularly in high-salinity environments.

Quantitative Analysis of Market Solutions

| Brand | Price (USD/linear foot) | Max Flow Rate (gpm) | Service Life (years) | Customization |

|---|---|---|---|---|

| PremiumPrePack | 85-120 | 450 | 15-20 | Full |

| HydroScreen Pro | 70-95 | 380 | 12-15 | Partial |

| EconoGravel | 45-60 | 250 | 8-10 | None |

Tailored Configurations for Diverse Applications

Specialized 2 inch well screen variants address niche requirements in geothermal and remediation projects. Customization parameters include:

- Slot sizes from 0.15mm to 3.0mm

- 316Ti or Hastelloy construction materials

- Radial compression strength up to 12,000 psi

For coastal projects in Louisiana, manufacturers developed zinc-coated screens achieving 92% corrosion resistance improvement over standard models.

Documented Operational Achievements

In Alberta's oil sands (2022), a 1.5-mile array of pre-packed screens maintained 98% operational efficiency through -40°C winter conditions. Post-installation monitoring showed:

- 27% reduction in pump maintenance

- 15% increase in daily output

- Zero screen replacements in 18 months

Pre Pack Well Screen: The Industry Benchmark

As drilling depths exceed 10,000 feet globally, integrated gravel pack screen systems prove essential. Current models withstand 25 MPa pressures while maintaining 0.2mm filtration accuracy - a 300% improvement over 2015 standards. Third-party verification from DNV GL confirms 100% compliance with API RP 19C standards across leading manufacturers.

(pre pack well screen)

FAQS on pre pack well screen

Q: What is a pre pack well screen used for?

A: A pre pack well screen filters sediment and prevents sand production in oil, gas, or water wells. It combines layered gravel packing and screen mesh for enhanced durability. This design improves filtration efficiency in high-sand environments.

Q: How does a gravel pack screen differ from a pre pack well screen?

A: Gravel pack screens require external gravel placement during installation, while pre pack screens come pre-filled with filter media. Pre pack models save installation time but cost more. Both serve sand control in subsurface formations.

Q: When would a 2 inch well screen be preferred?

A: A 2 inch well screen suits low-flow residential water wells or environmental monitoring boreholes. Its compact size enables installation in narrow-diameter casings. Smaller screens reduce costs for shallow, low-yield applications.

Q: What factors determine pre pack well screen longevity?

A: Material grade (stainless steel vs polymer), gravel-pack uniformity, and formation sand size impact lifespan. Proper slot sizing matching local sediment prevents clogging. Corrosion-resistant coatings extend service in saline environments.

Q: Can gravel pack screens handle fine sand particles?

A: Yes, if graded gravel matches formation sand size. Multi-layer gravel packing creates progressive filtration stages. Screen slot width must align with the smallest gravel layer to prevent bypass.