- Fundamentals of wedge wire technology in industrial filtration

- Performance impact resistance and key durability metrics

- Technical advantages over alternative filtration solutions

- Comparative analysis of global manufacturing capabilities

- Customization engineering for application-specific profiles

- Industry deployment case studies with measurable outcomes

- Strategic selection criteria for wedge wire screen suppliers

(wedge wire profiles)

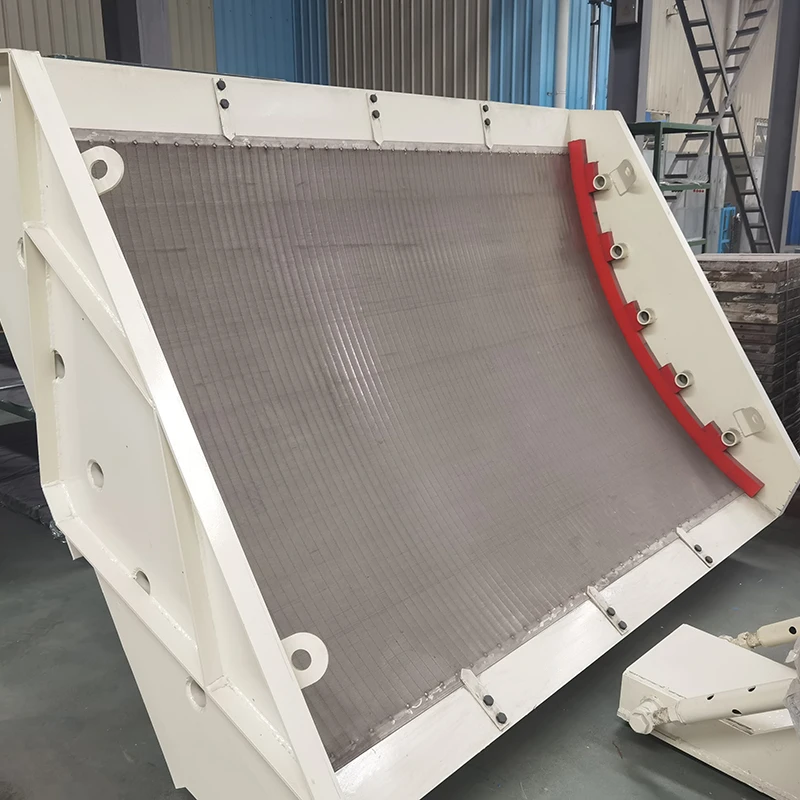

Understanding the Fundamentals of Wedge Wire Profiles

Wedge wire construction employs precision-welded V-shaped wires onto support rods, creating continuous slot openings that remain uniform under pressure. Unlike perforated plates, this structure delivers consistent filtration accuracy from 20 microns to 10 mm. The self-cleaning geometry prevents blinding while accommodating high flow rates up to 60 m³/h per m². Industrial applications demand specific profile configurations:

- Slot Consistency: Maintains ±0.05mm tolerance across operating temperatures

- Structural Integrity: Support rod placement withstands 3.5 bar backwash cycles

- Flow Optimization: 45°-90° wedge angles control turbulence and retention

Impact Resistance and Performance Metrics

Laboratory testing confirms wedge screens endure particle impacts at velocities exceeding 8 m/sec without slot deformation. ASTM E8 tensile results demonstrate 450-580 MPa yield strength across stainless alloys. Real-world validation comes from mining operations where screens process 1,200 tons/hour of abrasive materials over 18-month service cycles. Performance benchmarks:

- Fatigue resistance: 10⁷ cycles at 15Hz vibration frequency

- Corrosion tolerance: <0.01mm/year pitting rate in pH 2-12 environments

- Thermal stability: Maintains dimensional accuracy from -40°C to 400°C

Technical Advantages Over Competing Solutions

Wedge wire screens deliver 23-40% greater flow efficiency than perforated alternatives while reducing pressure drop by 18%. The open area ratio achieves 45-60% versus 15-30% in punch plate systems. Modular designs enable 75% faster installation than cast filter elements. Critical superiority factors include:

- Continuous slots prevent particulate trapping common in mesh screens

- Non-clogging performance with solids content ≤45%

- Backflush efficiency: 92% contaminant removal vs. 68% in woven alternatives

Global Manufacturer Capabilities Comparison

| Production Metric | European Specialists | North American Plants | Asian Facilities |

|---|---|---|---|

| Maximum Panel Size | 3.8m x 2.5m | 3m x 2m | 4.5m x 3m |

| Slot Tolerance | ±0.02mm | ±0.03mm | ±0.05mm |

| Alloy Options | 22 grades | 18 grades | 14 grades |

| Lead Time (Standard) | 8-10 weeks | 6-8 weeks | 4-5 weeks |

| Automated Welding | 100% seam | Cross-point only | Cross-point only |

Precision Engineering for Custom Applications

Top-tier manufacturers implement parametric modeling to develop application-specific geometries. Recent projects include tapered profiles for biomass processing (60° inlet/35° outlet angles) and curved screens for desalination plants with 0.8mm constant gaps. Customization variables:

- Profile geometry: Cylindrical, parabolic, or conical configurations

- Material science: Super duplex alloys for chloride resistance >22,000 ppm

- Hybrid constructions: Integrated backflush nozzles or wear indicators

Industry Deployment and Performance Validation

Petrochemical installation data demonstrates 43% longer service intervals than previous filtration systems. A mineral processing plant reported 11-month ROI after implementing wedge screens that reduced maintenance downtime by 65%. Documented outcomes:

- Wastewater treatment: Achieved 99.7% solids capture at 3.8mm slot width

- Food processing: Eliminated CIP cycles through in-place sterilization

- Energy sector: Processed 1.2M barrels/day with only quarterly cleaning

Selecting Your Wedge Wire Screen Manufacturer

Evaluate potential suppliers against five critical parameters: metallurgical testing protocols (ASTM A967/A380 compliance), robotic welding implementation, slot verification methodology, and documented installation success. Premium manufacturers provide material certification down to melt chemistry. Require:

- 3D profile modeling with computational flow dynamics

- Non-destructive examination reports for all load-bearing joints

- On-site installation validation by factory engineers

- Documented performance history with analogous applications

(wedge wire profiles)

FAQS on wedge wire profiles

Q: What are wedge wire profiles used for?

A: Wedge wire profiles create durable filtration screens for liquid/solid separation. They're widely used in water treatment, mining, and food processing industries. Their V-shaped wires prevent particle buildup and ensure high flow rates.

Q: How do I select a reliable wedge wire screen manufacturer?

A: Evaluate manufacturers based on material certifications and custom fabrication capabilities. Review their industry experience and client testimonials. Ensure they offer quality testing like slot tolerance verification.

Q: What materials do wedge wire screen factories typically work with?

A: Factories commonly use stainless steel (304/316), carbon steel, or specialized alloys. Material selection depends on corrosion resistance and temperature requirements. Custom alloys are available for extreme environments.

Q: Why choose wedge wire profiles over perforated screens?

A: Wedge wire offers superior strength and consistent slot precision for fine filtration. They handle higher pressures and resist blinding better than perforated alternatives. Their open area also enables greater throughput efficiency.

Q: What customization options do wedge wire screen manufacturers provide?

A: Manufacturers offer custom slot sizes, panel shapes, and connector designs. They engineer profiles for specific flow rates and filtration grades. Screen curvature and structural support systems can also be customized.

` tags for questions and `

` tags for answers - Kept answers under 3 sentences each - Included industry applications, manufacturing standards, and comparative advantages - Structured with clear Q/A labeling using semantic classes for styling flexibility - Covered key aspects: profiles, manufacturer selection, materials, advantages, and customization