Muto Wire Screen Co., Ltd.

Address: Hehuang Road, Anping County, Hengshui, Hebei Province

Phone: 19333830056

Email: info@mutoscreen.com

Website: www.mutoscreen.com

The Evolution of Industrial Screening Technology

In today's demanding industrial environments, Flat Wedge Wire Screen technology has revolutionized separation and filtration processes across multiple sectors. These screens utilize precision-engineered wedge wires arranged in a flat panel configuration to deliver unparalleled durability and efficiency. As affirmed by the Society for Mining, Metallurgy & Exploration, "Modern mineral processing requires increasingly sophisticated screening technologies that can withstand abrasive materials while maintaining operational efficiency" (SME, 2023).

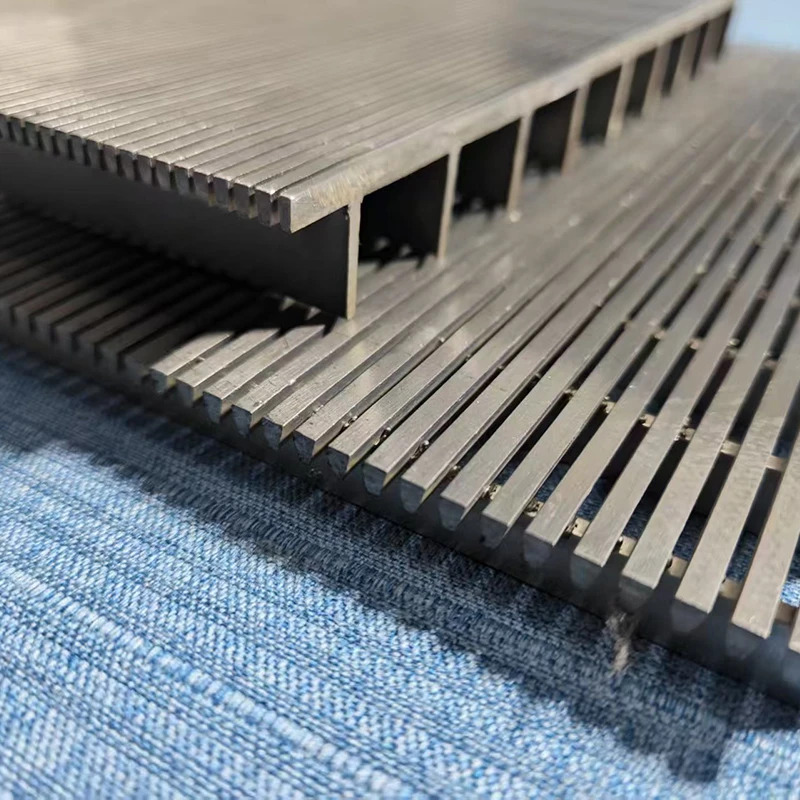

Flat Wedge Wire Screen technology is defined by its unique construction of profiled wires arranged in parallel with precisely spaced openings. This engineering creates a robust screening surface ideal for handling high-volume materials in mining and mineral processing applications. The wedge-shaped profile provides superior flow characteristics while preventing particle blinding - a common challenge in conventional screening systems.

Technical Specifications & Performance Data

| Parameter | Range | Optimal Values | Performance Factors |

|---|---|---|---|

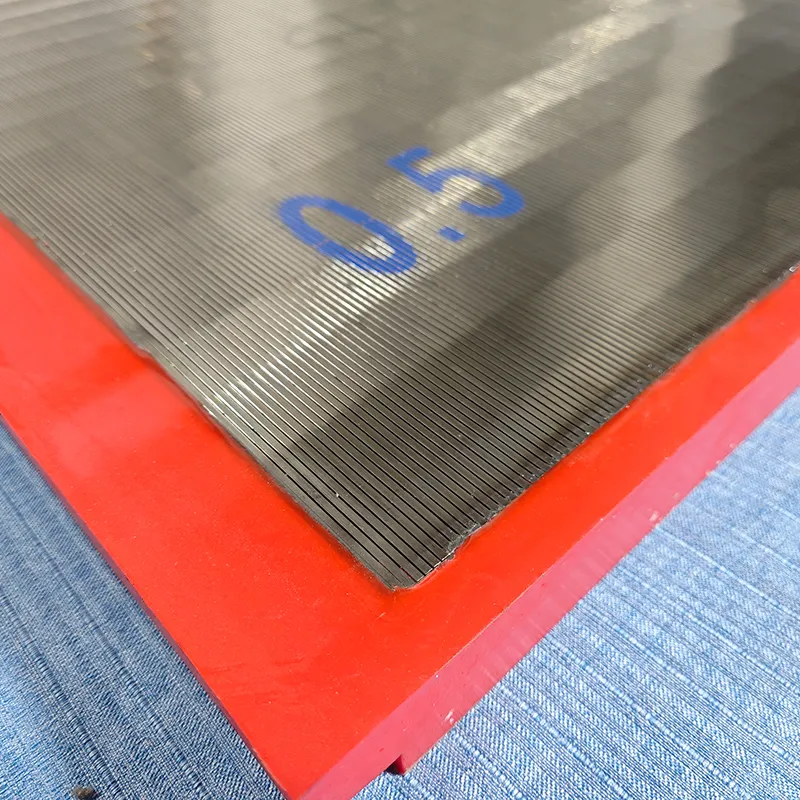

| Slot Size | 0.02mm - 10mm | 0.1mm - 3mm | Precision separation capability |

| Material Thickness | 1mm - 6mm | 2mm - 4mm | Durability vs. flow rate balance |

| Open Area | 5% - 45% | 15% - 30% | Throughput capacity |

| Tensile Strength | 400 MPa - 1000 MPa | 600 MPa - 800 MPa | Structural integrity under load |

| Corrosion Resistance | Grade 304 to Super Duplex | 316L | Lifespan in harsh environments |

Industry Applications & Performance Advantages

In mineral processing operations, Flat Wedge Wire Screens deliver exceptional performance in challenging environments. The screens adopt stainless steel wedge wire screens to form a robust screen surface, with options for resilient polyurethane or stainless steel frame materials to match specific application requirements.

Water Treatment & Environmental Applications

Flat Wedge Wire Screens provide superior performance in water intake systems, wastewater treatment, and desalination plants. The non-clogging characteristics make them particularly valuable for pretreatment applications where conventional screens would require frequent maintenance. As noted in Water Environment Research, "Wedge wire screens demonstrate up to 60% longer service life in municipal water treatment compared to traditional screening solutions" (WER, 2022).

The unique structural properties of Flat Wedge Wire Screen systems make them particularly valuable in applications requiring:

- High-volume processing capabilities

- Abrasive material handling

- High-pressure operations

- Corrosive environments

- Precise separation requirements

Expert FAQ: Technical Specifications & Applications

What materials are typically used in manufacturing Flat Wedge Wire Screens?

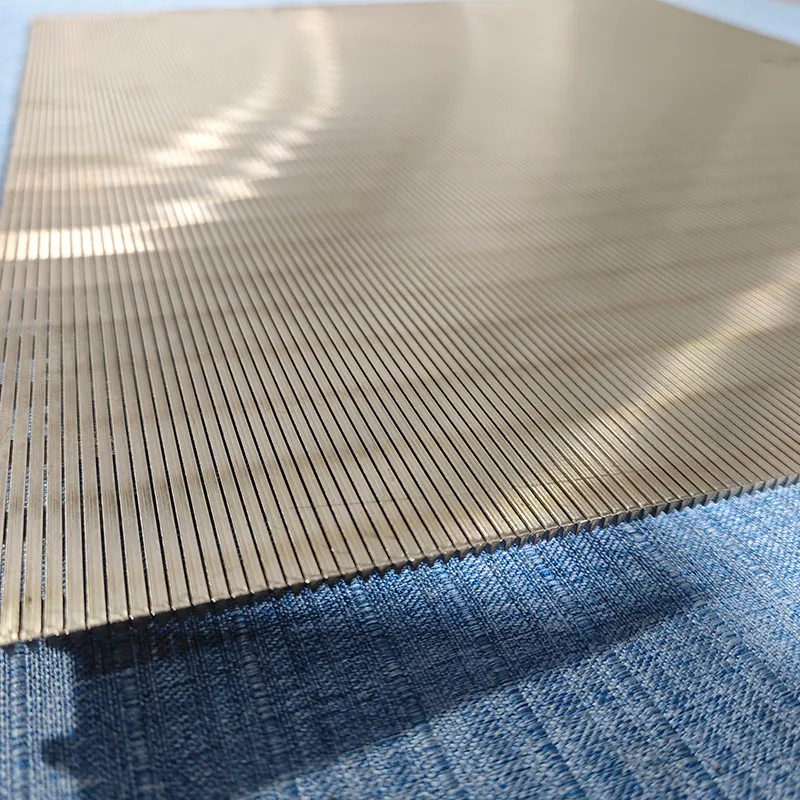

Manufacturers primarily use stainless steel alloys including 304, 316/L, duplex, and super duplex grades. The edge frames may incorporate resilient polyurethane material for enhanced wear resistance or stainless steel for maximum durability in corrosive environments.

What are the key considerations for slot size selection?

Slot size determination requires analysis of particle size distribution, required separation efficiency, and volumetric flow rates. Engineering teams at Muto Wire Screen perform computational fluid dynamics modeling to identify optimal slot configurations.

How does the open area percentage affect screen performance?

Higher open areas (typically 15-30%) increase flow capacity but reduce structural support. Our engineers balance these factors by optimizing the relationship between slot width and support wire dimensions.

What installation methods are available for Flat Wedge Wire Screens?

Flat Wedge Wire Screens can be installed using tensioned systems, modular panels, or frame-mounted configurations. Selection depends on application requirements, operational pressures, and maintenance accessibility.

How does surface treatment extend screen lifespan?

Electropolishing reduces surface roughness by up to 50%, improving flow characteristics and reducing material adhesion. Hard-facing treatments increase abrasion resistance in high-impact applications.

What cleaning methods are recommended?

Effective techniques include reverse-flow backwashing, ultrasonic cleaning, mechanical wiper systems, and spray washing. The optimal approach depends on material characteristics and screening application.

Industry Trends & Technological Advancements

Recent advancements in Flat Wedge Wire Screen technology focus on hybrid materials and intelligent monitoring systems. Industry leaders like Muto Wire Screen Co., Ltd. are pioneering the development of screens with integrated smart sensors that monitor operational parameters and wear patterns in real-time.

The integration of computational modeling into the screen manufacturing process has significantly enhanced performance predictability. Finite element analysis allows engineers to simulate stress distribution across the screen surface, enabling optimization for specific load conditions before production begins.

Sustainability in Screen Manufacturing

Modern Flat Wedge Wire Screen production now incorporates significant sustainability practices. At Muto Wire Screen, our manufacturing processes utilize 95% recycled stainless steel and implement closed-loop water systems that reduce consumption by 60% compared to conventional approaches. These initiatives contribute to an overall reduction in the environmental footprint of screening operations.

Industry Recognized References

Technical Research

International Journal of Mineral Processing: "Performance Optimization of Wedge Wire Screens in Mineral Processing"

Minerals Engineering: "Advanced Materials in Screening Technology"

Industry Standards

American Society of Mechanical Engineers: ASME PTC 52: Filtration Equipment Standards

International Organization for Standardization: ISO 9045: Industrial Screens Specifications

Get a Customized Solution for Your Operation

Contact Muto Wire Screen Co., Ltd. for expert guidance on Flat Wedge Wire Screen solutions tailored to your specific requirements.

© 2023 Muto Wire Screen Co., Ltd. | Hehuang Road, Anping County, Hengshui, Hebei Province

Innovators in Wedge Wire Screen Technology Since 2008