Scraper Centrifuge Unloader: Enhancing Efficiency in Industrial Separation Processes

As industries continue to evolve, the need for advanced machinery that improves productivity and reduces operational costs has never been more critical. MutoScreen Co., Ltd., a leading innovator in industrial separation solutions, introduces the Scraper Centrifuge Unloader—a cutting-edge system designed to revolutionize material handling in centrifugal separation processes. This article explores the technology, benefits, and applications of the Scraper Centrifuge Unloader, highlighting how it addresses key industry challenges and delivers unmatched performance.

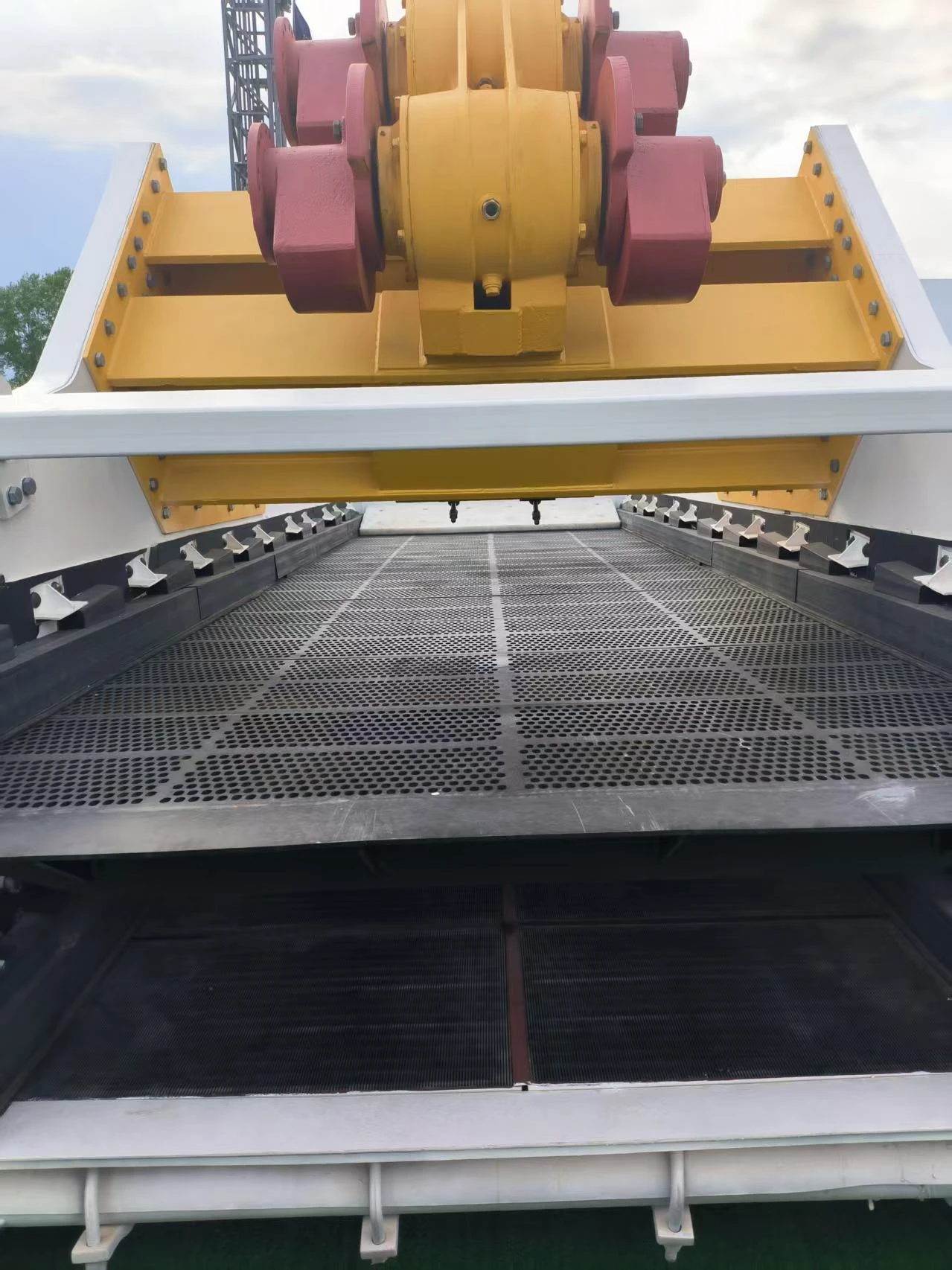

Understanding the Scraper Centrifuge Unloader

The Scraper Centrifuge Unloader is a specialized device engineered to efficiently remove solid materials from centrifugal separators. By integrating a scraper mechanism with centrifugal force, this system ensures complete and rapid discharge of solids, minimizing downtime and maximizing throughput. Its design is optimized for industries such as chemical processing, food and beverage, pharmaceuticals, and waste management, where precise and efficient material separation is essential.

Addressing Industry Challenges

Traditional centrifugal separation processes often face challenges such as incomplete material discharge, clogging, and high maintenance costs. The Scraper Centrifuge Unloader tackles these issues head-on:

- Efficient Discharge: The scraper mechanism ensures thorough removal of solids, reducing residue and preventing blockages.

- Reduced Downtime: By minimizing the need for manual intervention, the system enhances operational efficiency.

- Cost-Effective Maintenance: Durable materials and a streamlined design lower long-term maintenance expenses.

Why Choose MutoScreen Co., Ltd.?

With decades of expertise in industrial separation technology, MutoScreen Co., Ltd. has established itself as a trusted partner for businesses seeking reliable and innovative solutions. Our commitment to research and development has led to the creation of the Scraper Centrifuge Unloader, a product that combines advanced engineering with practical usability. Key advantages include:

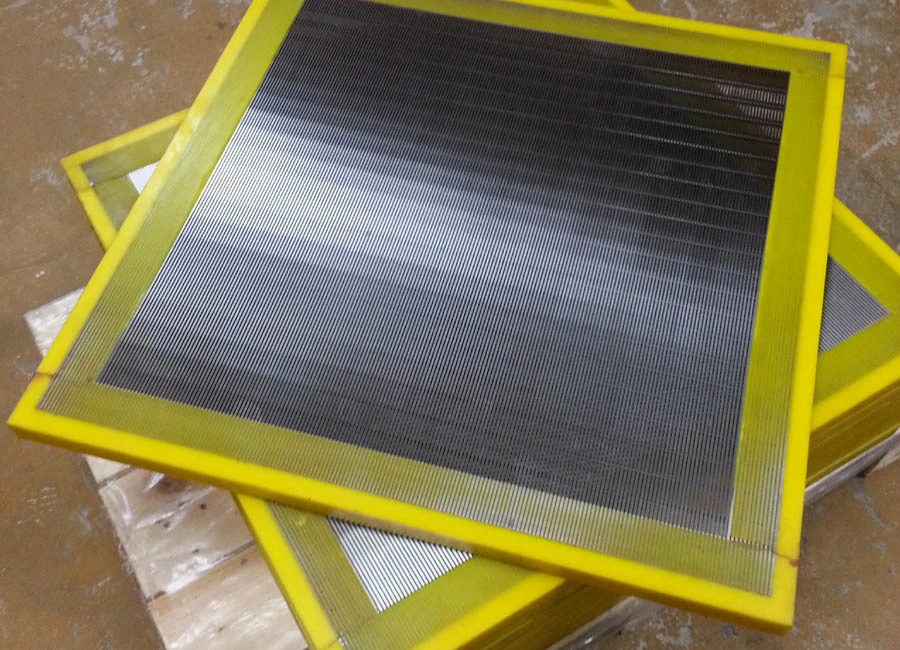

- Technical Excellence: State-of-the-art design and materials ensure durability and performance under demanding conditions.

- Customization: Tailored solutions to meet the unique requirements of different industries and applications.

- Comprehensive Support: From installation to after-sales service, our team provides end-to-end assistance.

Real-World Applications

The Scraper Centrifuge Unloader is widely used in various sectors, including:

- Chemical Industry: Efficient separation of solids from chemical slurries and by-products.

- Food and Beverage: Precise removal of solids from liquid products, ensuring hygiene and quality.

- Pharmaceuticals: Reliable separation of active ingredients and excipients during production.

- Waste Management: Effective processing of sludge and organic waste for recycling and disposal.

Customer Testimonials

Industry leaders have praised the Scraper Centrifuge Unloader for its transformative impact:

"Since implementing the Scraper Centrifuge Unloader, our production efficiency has increased by 30%. The reduction in downtime has significantly lowered our operational costs." – John Doe, Production Manager, ABC Chemicals

"The system's reliability and ease of maintenance have made it a cornerstone of our operations. MutoScreen's support has been exceptional." – Jane Smith, Plant Director, XYZ Foods

Implementation and Support

Adopting the Scraper Centrifuge Unloader involves a seamless process, from initial consultation to installation and training. Our team works closely with clients to ensure optimal integration into existing workflows. Additionally, we offer:

- Technical Consultation: Expert advice on system configuration and optimization.

- Training Programs: Comprehensive training for operators and maintenance staff.

- 24/7 Support: Prompt assistance to resolve any issues and ensure continuous operation.

Commitment to Safety and Compliance

Safety is a top priority at MutoScreen Co., Ltd. The Scraper Centrifuge Unloader adheres to international standards for industrial equipment, ensuring a secure working environment. Its design incorporates features such as:

- Robust Construction: Resistant to corrosion and wear, ensuring long-term reliability.

- Safe Operation: Protective mechanisms to prevent accidents and equipment failure.

- Environmental Compliance: Designed to minimize waste and reduce environmental impact.

Delivery and Packaging

We understand the importance of timely and secure delivery for industrial clients. The Scraper Centrifuge Unloader is packaged in reinforced containers to withstand transportation challenges. Our logistics partners ensure prompt delivery worldwide, with tracking information provided for transparency.

Get in Touch

Ready to elevate your industrial separation processes? Contact MutoScreen Co., Ltd. today to learn more about the Scraper Centrifuge Unloader and how it can benefit your operations. Visit our website or reach out via phone at +1-800-123-4567 for personalized assistance.

FAQs

What industries can benefit from the Scraper Centrifuge Unloader?

The system is ideal for chemical processing, food and beverage, pharmaceuticals, and waste management sectors where efficient solid-liquid separation is critical.

How does the scraper mechanism improve efficiency?

The scraper ensures complete discharge of solids, reducing residue and preventing clogging, which minimizes downtime and maintenance costs.

Is technical support available after purchase?

Yes, we provide 24/7 technical support, training, and maintenance services to ensure seamless operation.

Conclusion

The Scraper Centrifuge Unloader from MutoScreen Co., Ltd. offers a powerful solution to modern industrial separation challenges. With its advanced design, reliability, and customer-centric support, it is a valuable asset for any business aiming to enhance productivity and reduce costs. Discover the difference today at www.mutoscreen.com.