- Understanding the Fundamentals of Dewatering Screen Technology

- Technical Advantages Driving Modern Dewatering Screen Efficiency

- Critical Selection Criteria for Dewatering Screen Panels

- Manufacturer Comparison: Performance Metrics Analysis

- Custom Engineering Solutions for Specific Applications

- Industry-Specific Implementation Case Studies

- Maximizing ROI with Dewatering Screen Panel Optimization

(dewatering screen panels)

Understanding Dewatering Screen Technology Fundamentals

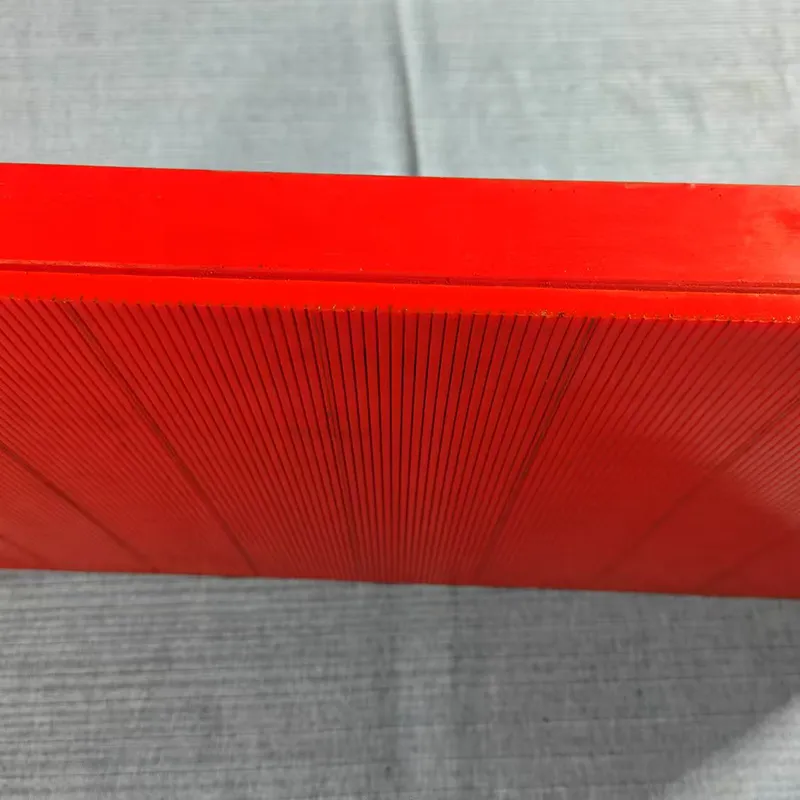

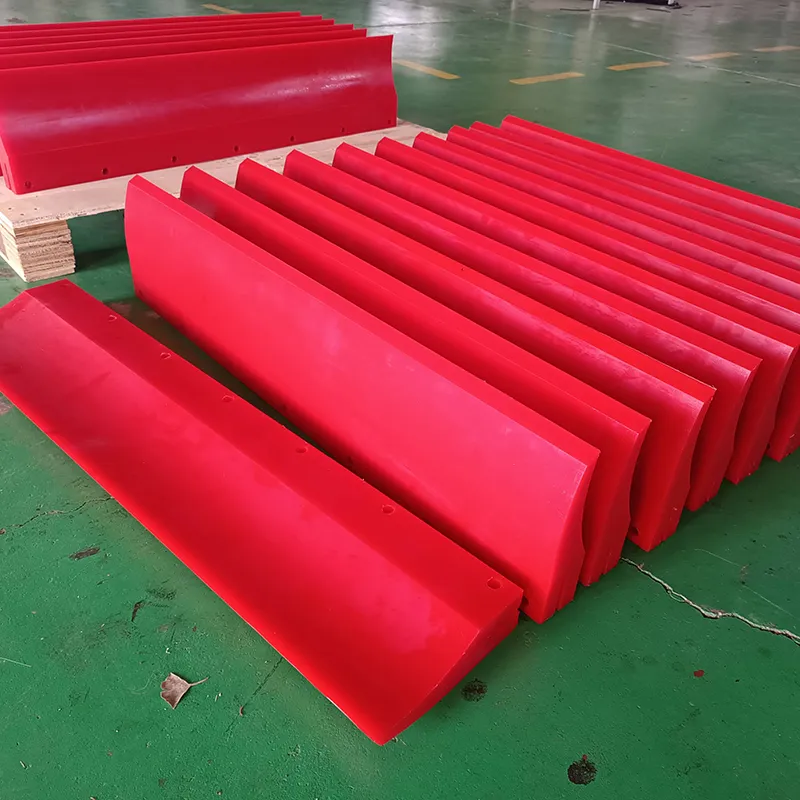

Dewatering screen panels serve as critical components in solid-liquid separation processes across multiple industries. These specialized screening surfaces enable efficient water removal from materials like sand, coal, and minerals through precise aperture designs. The mechanics involve high-frequency vibration combined with upward deck inclination (typically 3-5°) to accelerate drainage while retaining solid particles. Properly functioning dewatering screens can reduce moisture content by 40-70% compared to static drainage methods, immediately impacting downstream processing efficiency.

Modern dewatering vibrating screens operate at frequencies between 700-1000 RPM with G-forces of 4-6g to optimize particle stratification. Polyurethane panels with dual-hardness compositions (60-95 Shore A) now dominate premium installations due to their 300-500% longer service life versus conventional rubber variants. Progressive operations utilize multi-stage configurations featuring primary drainage zones (1-1.5mm slots) followed by polishing sections (0.2-0.6mm) to achieve final moisture levels of 8-15% in sand and 15-22% in mineral concentrates.

Technical Advantages Driving Modern Dewatering Screen Efficiency

Advanced panel designs incorporate hydrodynamic principles to overcome common dewatering limitations. Tapered slot technology prevents blinding by expanding inlet openings 20-30% wider than outlet dimensions. Polymer-infused urethane compounds with hydrophobic additives accelerate water drainage by up to 40% compared to standard formulations. Leading manufacturers now embed wear indicators within panel substrates that signal replacement thresholds before catastrophic failure occurs.

Industry testing confirms that directional elastomer panels outperform rigid screens in high-abrasion applications. In iron ore processing trials, urethane variants maintained flow capacity for 3,100 operational hours versus metal screens' 900-hour average before significant efficiency degradation. Enhanced durability translates to 28% lower annual replacement costs according to aggregate industry metrics. The combination of strategic panel angulation and variable vibration frequencies allows operators to fine-tune processes for materials with fines content exceeding 25% without sacrificing throughput.

Critical Selection Criteria for Dewatering Screen Panels

Panel specification requires consideration of seven key parameters: material abrasion index (0-100 Ai), particle size distribution curve, solids concentration, target moisture percentage, throughput requirements, chemical compatibility, and installation geometry. For silica sand applications, manufacturers typically recommend 75-85 Shore A urethane with 0.3mm slots, while coal processing demands 65-75 Shore A with wider 1.25mm openings to handle variability.

Modular panel systems have largely superseded monolithic designs due to their replaceable wear zones and elimination of unscreened dead areas. Leading installations utilize tapered wedge systems allowing individual panel replacement within 8 minutes without specialized tools. Proper tensioning methodology prevents premature failure - under-tensioned panels develop harmonic oscillations causing fatigue cracks, while over-tensioning accelerates slot deformation.

Manufacturer Comparison: Performance Metrics Analysis

| Manufacturer | Slot Tolerance (±mm) | Abrasion Resistance (cu.m/kg) | Max Temp (°C) | Open Area (%) | Warranty Period |

|---|---|---|---|---|---|

| Premium Polyurethane Systems | 0.03 | 150 | 110 | 32 | 18 months |

| Global Screening Solutions | 0.05 | 90 | 85 | 28 | 12 months |

| Industrial Screening Technologies | 0.08 | 65 | 75 | 25 | 9 months |

| Standard OEM Panels | 0.12 | 45 | 65 | 18 | 6 months |

Field studies demonstrate premium urethane panels achieving 23% higher throughput retention at 6-month intervals compared to economy alternatives. Operations processing 500 tonnes/hour typically realize payback periods under 5 months when upgrading to precision-engineered panels.

Custom Engineering Solutions for Specific Applications

Adaptation of dewatering screens requires calculated modifications to standard configurations. For brine crystallization processes, corrosion-resistant compounds incorporating nitrile additives are essential. Petrochemical applications utilize carbon-infused urethane with 65±5 IRHD hardness to mitigate hydrocarbon swelling effects. Mining installations facing high-impact loading now implement reinforced steel inserts that increase fatigue resistance by 300%.

Recent innovation includes radial slot arrays for complex ores requiring multi-vector drainage. Directional slot technology achieves 22% greater efficiency in flake material processing versus linear patterns. For facilities with confined footprints, vertical dewatering systems with static screens augmented by pneumatic vibrators have proven effective in tailings operations where inclination angles exceed spatial allowances.

Industry-Specific Implementation Case Studies

A Florida phosphate operation increased production capacity by 17% after transitioning to directional flow panels, reducing screen blinding events from weekly to quarterly occurrences. The customized solution combined three panel zones with progressively tighter apertures (1.2mm→0.4mm) while maintaining 600 tonne/hour throughput, ultimately decreasing moisture content from 18% to 13.5%.

Canadian oil sands extraction facilities recorded a 31% reduction in maintenance costs after installing hydrolysis-resistant panels with embedded temperature sensors. The monitoring system alerts operators to abnormal friction build-up before critical failures occur, extending mean service life from 8 to 14 months. Similarly, municipal wastewater plants report significant operational improvements with dual-durometer panels that resist biological fouling while maintaining 98% screening efficiency through storm events.

Maximizing ROI Through Dewatering Screen Panel Optimization

Strategic panel management delivers measurable financial returns. Progressive operations conduct quarterly wear mapping to identify high-impact replacement zones rather than complete system overhauls. This approach decreases material costs by 35-50% while maintaining performance standards. Automated tension monitoring systems represent another advancement, with installations reporting 29% fewer unplanned downtime hours.

Leading mineral processors now correlate panel specifications to specific ore characteristics. One copper concentrator implemented variable panel designs throughout their screening circuit, resulting in an 11% increase in recovery rates. When evaluating dewatering vibrating screen investments, factor replacement costs per tonne processed rather than absolute panel expense. Premium systems typically demonstrate costs below $0.09/tonne at optimal operational levels compared to $0.22/tonne for budget alternatives requiring more frequent changes. Ongoing panel performance analysis provides actionable insights for continuous process enhancement.

(dewatering screen panels)

FAQS on dewatering screen panels

Q: What are dewatering screen panels used for?

Q: What are dewatering screen panels used for?A: Dewatering screen panels separate solids from liquids in materials like sand, coal, or minerals. They enable efficient water removal while retaining fine particles. Their high open area and durability suit demanding industries like mining and wastewater treatment.

Q: How does a dewatering vibrating screen work?

Q: How does a dewatering vibrating screen work?A: A dewatering vibrating screen uses high-frequency vibrations to shake excess water from materials. The vibrations force liquids through the screen panels while moving solids forward for discharge. This process reduces moisture content and improves material handling.

Q: What materials are dewatering screen panels made from?

Q: What materials are dewatering screen panels made from?A: Dewatering screen panels are typically made from polyurethane, rubber, or stainless steel. Polyurethane panels offer wear resistance and flexibility, while stainless steel suits heavy-duty applications. Material choice depends on abrasion levels and operational conditions.

Q: How to maintain a dewatering screen?

Q: How to maintain a dewatering screen?A: Regularly inspect screen panels for wear or clogging and clean them with water or brushes. Check vibration motors and bearings for proper lubrication. Replace damaged panels promptly to maintain efficiency and prevent downtime.

Q: Where are dewatering screens commonly applied?

Q: Where are dewatering screens commonly applied?A: Dewatering screens are used in mining, aggregate production, and wastewater treatment. They also serve in recycling, chemical processing, and food production. Their ability to handle slurry makes them ideal for moisture reduction in bulk materials.