In the vast landscape of industrial filtration and separation, the efficiency and reliability of screening media are paramount. The global market for industrial filtration is projected to reach USD 49.3 billion by 2028, growing at a CAGR of 6.2%, a trend driven by stringent environmental regulations and the increasing need for process optimization. Within this market, the wedge wire screen for sale stands out as a superior technology. This comprehensive guide delves into every facet of the wedge wire screen, also known as a `wedge wire mesh` or `sieve bend screen`, exploring its technical intricacies, vast applications, manufacturing excellence, and how to source the perfect customized solution for your needs.

What is a Wedge Wire Screen? A Deep Dive into the Technology

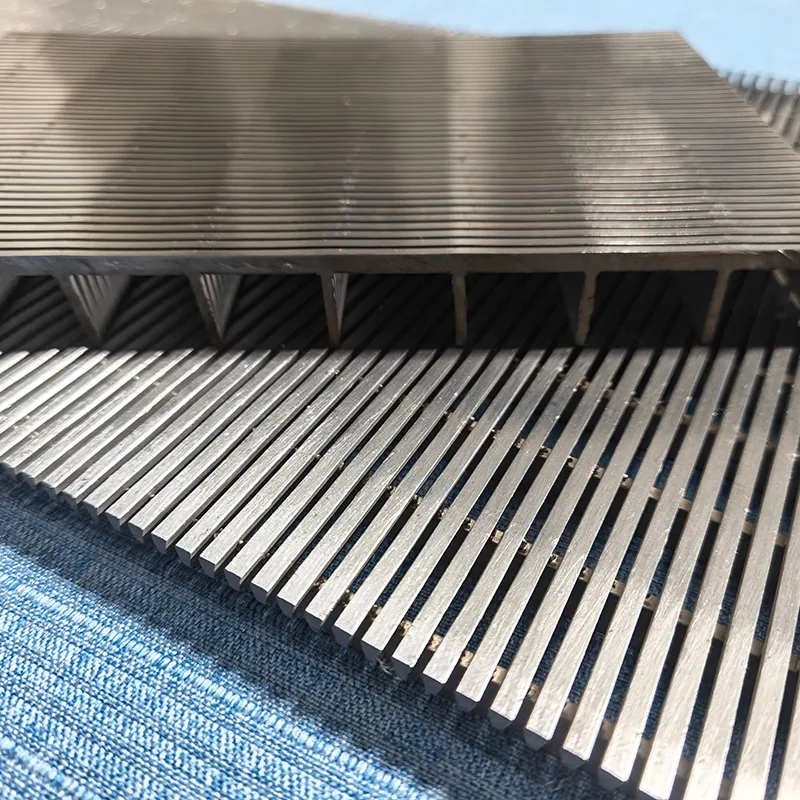

A `wedge wire screen`, at its core, is a sophisticated mechanical filter element constructed from V-shaped profile wires (surface profiles) that are resistance-welded onto support rods at regular intervals. Unlike traditional woven wire mesh or perforated plates, the geometry of a `wedge wire filter screen` offers unique advantages.

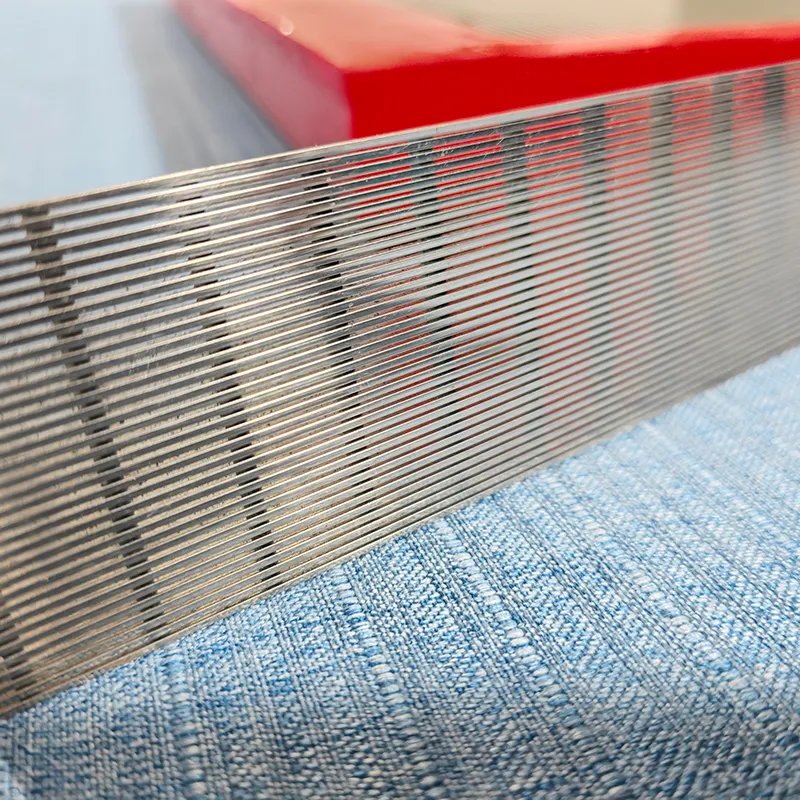

The key lies in its construction: the V-shaped wires form slots that widen inwardly. This design, known as V-profile or triangular wire, creates only two-point contact with particles, minimizing the risk of clogging or pegging. This continuous slot arrangement provides a massive open area, leading to significantly lower pressure drop and higher throughput compared to other screen types. This makes it an ideal choice for a multitude of separation, filtration, dewatering, and retention tasks.

Core Components & Terminology Explained

- Surface Wire (Profile Wire): The V-shaped wire on the screen's surface that performs the filtration. Its size and shape determine the slot opening and wear characteristics.

- Support Rods: The underlying rods that the surface wires are welded to. They provide structural integrity and strength to the screen assembly.

- Slot Size (Aperture): The precise distance between adjacent surface wires. This is the most critical parameter, as it dictates the particle size that will be retained or passed through. Slot sizes can be controlled with extreme precision, often down to microns.

- Open Area: The total area of the slots as a percentage of the total screen area. A higher open area generally translates to higher capacity and lower pressure drop. `Wedge wire screens` typically offer a significantly higher open area than perforated plates with equivalent separation capabilities.

The Manufacturing Journey: From Raw Material to High-Performance Screen

The performance of a `wedge screen` is directly tied to the quality of its manufacturing process. At MUTO Screen, we adhere to stringent `ISO 9001:2015` quality management standards throughout our production cycle. Here is a detailed look at how a high-quality wedge wire screen for sale is made:

1. Raw Material Inspection

Material verification (e.g., SS 304/316L/Duplex via PMI testing) per `ASTM A580/A580M` standards.

2. Wire Drawing & Shaping

High-grade wire is drawn and precisely shaped into the required V-profile.

3. CNC Automated Welding

V-wires are resistance-welded to support rods with robotic precision for consistent slot size.

4. Cutting & Fabrication

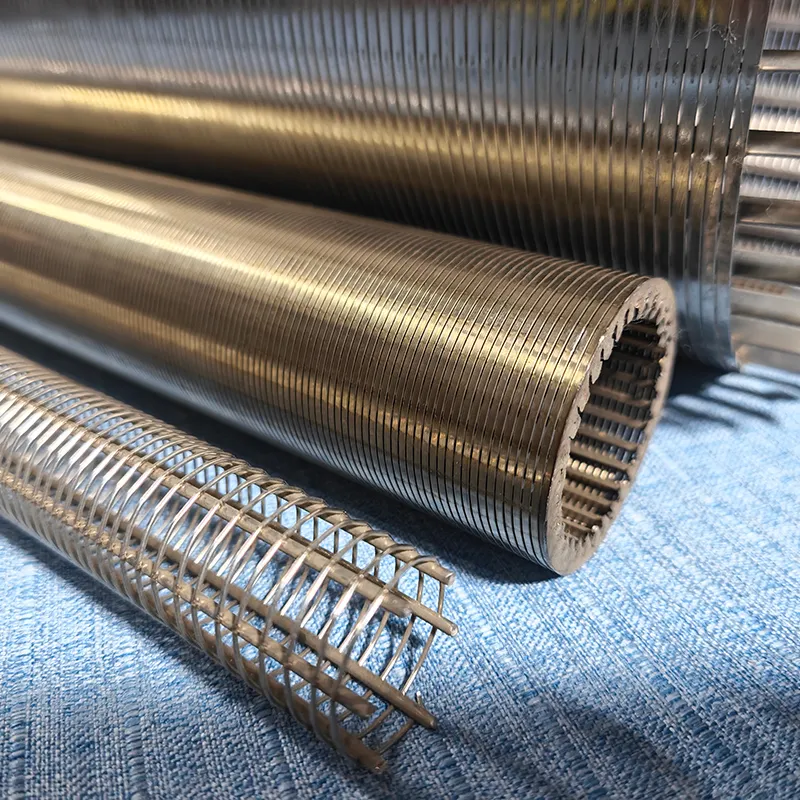

Screens are cut, rolled, or fabricated into cylinders, flat panels, or custom shapes.

5. Surface Treatment

Includes pickling and passivation to enhance corrosion resistance and ensure hygiene.

6. Final Quality Control

Dimensional checks, slot size verification, and weld integrity tests are performed.

This automated, precision-driven process ensures every screen we produce offers unparalleled consistency and durability, far exceeding the lifespan of screens made with inferior methods. The resistance welding technique creates a strong, integral bond between the profile wire and support rod, forming a single, robust unit that can withstand high pressures and abrasive materials.

Technical Specifications and Data-Driven Insights

When searching for a wedge wire screen for sale, understanding the technical parameters is crucial for selecting the right product. Below is a typical specifications table, followed by data visualizations illustrating market and performance metrics.

Wedge Wire Screen Standard Parameters

| Parameter | Typical Specification Range | Significance |

|---|---|---|

| Material Grade | AISI 304, 316L, 321, Duplex 2205, Hastelloy, Titanium | Determines corrosion resistance, temperature tolerance, and strength. 316L is common for its excellent corrosion resistance. |

| Slot Size | 0.025 mm (25 microns) to 10 mm | The most critical parameter for filtration efficiency. Must be selected based on the particle size to be separated. |

| Profile Wire (V-Wire) | Width: 1.0mm - 4.5mm; Height: 2.0mm - 7.0mm | Larger wires offer greater strength and wear life, while smaller wires can achieve finer slots and higher open areas. |

| Support Rod | Width: 2.0mm - 5.0mm; Height: 3.0mm - 8.0mm | Provides the structural backbone. The size and spacing determine the screen's overall strength and load-bearing capacity. |

| Open Area | 10% - 60% | A higher open area leads to greater flow capacity and less pressure drop. Varies based on slot size and wire profile. |

| Screen Type | Flat Panels, Cylinders (Tubes), Baskets, Sieve Bend Screens | The form factor is determined by the specific application and equipment design. |

Data Visualization: Performance and Market Analysis

Visual data helps contextualize the performance and market positioning of wedge wire technology.

Performance Comparison: Open Area vs. Strength

Chart illustrates how `wedge wire screens` offer a superior balance of high open area (for flow) and structural strength compared to alternatives.

Unmatched Technical Advantages of Wedge Wire Screens

The unique geometry and robust construction of a `wedge screen` translate into a host of operational benefits that drive efficiency and reduce costs across industries.

Non-Clogging Surface

The V-shaped profile creates a slot that widens inwardly, ensuring that any particle small enough to pass the surface is easily cleared. This significantly reduces downtime for cleaning and boosts operational continuity.

High Precision & Efficiency

Manufacturing allows for extremely precise slot openings, resulting in accurate and reliable particle separation. This is critical in applications like catalyst retention and fine particle filtration.

Superior Strength & Durability

The welded construction creates a very strong, rigid screen that can withstand high pressures, differential loads, and abrasive materials. This leads to a longer service life, with lifespans often exceeding 5-10 years even in harsh conditions.

High Open Area & Low Pressure Drop

The continuous slot design maximizes the open area, allowing for higher flow rates with minimal pressure loss. This translates to energy savings, as less pumping power is required.

Excellent Corrosion Resistance

Fabricated from materials like Stainless Steel 316L or Duplex, `wedge wire filter screens` offer exceptional resistance to chemical corrosion and high temperatures, making them suitable for the most demanding environments like petrochemical plants and desalination facilities.

Versatility in Design

Can be fabricated into nearly any shape or size—flat, curved, cylindrical, or conical. This adaptability allows them to be integrated into a wide range of new and existing equipment, from well screens to architectural grilles.

Sourcing Excellence: Manufacturer Comparison

Not all providers of wedge wire screen for sale are equal. Choosing the right manufacturer is as critical as selecting the right specifications. Here’s a comparison to highlight what you should look for.

| Feature | Generic Supplier | MUTO Screen (Specialist) |

|---|---|---|

| Material Certification | May be unavailable or basic. | Provided for every batch (e.g., MTRs for SS 316L), full traceability. |

| Customization Capability | Limited to standard sizes. | Fully customizable: slot, wire, rods, material, and end fittings. |

| Technical Support | Basic sales support. | Expert engineering support for design, material selection, and optimization. |

| Quality Assurance | Basic visual inspection. | ISO 9001:2015 certified; multi-point inspection including weld and slot checks. |

| Lead Time & Delivery | Variable, often long. | Transparent lead times (e.g., standard 2-4 weeks), reliable logistics. |

| Warranty & After-Sales | Limited or no warranty. | Comprehensive warranty and dedicated customer support for installation and maintenance. |

The Power of Customization: Tailoring Your Wedge Wire Solution

Off-the-shelf solutions rarely provide optimal performance. A key advantage of working with a specialist manufacturer is the ability to fully customize your `wedge wire screen`. This ensures the product is perfectly engineered for your specific process conditions, maximizing efficiency and lifespan.

Customization options include:

- Material Selection: Choosing the ideal alloy for your specific chemical, temperature, and abrasive environment.

- Slot Size and Wire Profile: Engineering the perfect combination to achieve the desired filtration efficiency, flow rate, and strength.

- Structural Design: Adding reinforcements, frames, or special end fittings for easy integration into your existing equipment.

- Surface Finish: Options like electropolishing are available for sanitary applications (e.g., food and beverage) to improve cleanability and reduce biofouling.

By investing in a custom solution, you are not just buying a part; you are investing in process optimization. Find your ideal wedge wire screen for sale by discussing your unique needs with our engineering team.

Application Showcase: Where Wedge Wire Screens Excel

The versatility of `wedge wire mesh` allows it to be a cornerstone technology in numerous industries. Its robust and efficient nature solves critical separation challenges.

Case Study 1: Mineral Processing (Sieve Bend Screen)

Industry: Mining & Aggregates

Challenge: A coal processing plant was using polyurethane panels for dewatering fine coal slurry. The panels suffered from frequent clogging and rapid wear, leading to high maintenance costs and significant operational downtime.

Solution: A custom-designed `sieve bend screen` from MUTO Screen was installed. Made from abrasion-resistant stainless steel with a precise 0.5mm slot, the screen utilized the Coandă effect for highly efficient static dewatering.

Outcome: The plant reported a 40% reduction in screen maintenance downtime and a 15% increase in dewatering efficiency. The screen's lifespan was over three times that of the previous polyurethane panels, providing a rapid return on investment.

Case Study 2: Municipal Water Intake

Industry: Water & Wastewater Treatment

Challenge: A municipal water treatment facility's raw water intake was struggling with debris and aquatic life, causing frequent pump blockages and violating environmental standards for fish protection (`316(b) Clean Water Act`).

Solution: Passive intake screens made from `wedge wire` were installed. The T-shape design and low through-slot velocity (

Outcome: Pump maintenance was reduced by over 80%. The facility achieved full compliance with environmental regulations. The system has operated flawlessly for over 5 years with minimal manual intervention, ensuring a reliable supply of raw water.

Case Study 3: Food & Beverage (Lauter Tun Screens)

Industry: Brewing

Challenge: A craft brewery was experiencing inconsistent wort clarity and slow lautering times with their traditional perforated false bottom.

Solution: The old system was replaced with a custom-fabricated `wedge wire` false bottom. The precise slot control and high open area allowed for a more uniform grain bed, better extraction, and faster runoff without pulling grain particles through.

Outcome: Lautering time was reduced by 25%, increasing brewhouse turnover. The brewery saw a measurable improvement in wort clarity and a 2% increase in brew house yield, directly boosting profitability.

Frequently Asked Questions (FAQ)

1. How do I determine the correct slot size for my application?

The correct slot size is typically determined by the size of the smallest particle you need to retain. A general rule is to select a slot size that is 50-70% of the D85 particle size of the media to be retained (meaning 85% of the particles are larger than this size). However, factors like particle shape, desired flow rate, and fluid viscosity are also crucial. We highly recommend consulting with our engineers for a detailed analysis of your process to ensure optimal selection.

2. What is the difference between Stainless Steel 304 and 316L for a wedge wire screen?

SS 304 is a great general-purpose stainless steel with good corrosion resistance. SS 316L, however, contains molybdenum, which significantly enhances its resistance to chlorides and other corrosive agents. SS 316L is the preferred choice for marine environments, chemical processing, wastewater, and food/pharmaceutical applications where pitting corrosion is a concern. For highly corrosive environments, we may recommend Duplex steels or other exotic alloys.

3. How do you clean a wedge wire screen?

Cleaning is straightforward due to the non-clogging design. Methods include backwashing (reversing the flow), scraping with a non-abrasive tool, high-pressure water jetting, or chemical cleaning (CIP). For passive intake screens, an automated airburst or water-jet system is often integrated. The best method depends on the screen type and the nature of the foulant.

4. What is the typical lifespan of a wedge wire screen?

Lifespan is highly dependent on the application's abrasiveness, corrosiveness, and operating pressure. However, thanks to their robust, all-welded construction, `wedge wire screens` are exceptionally durable. In non-abrasive applications like water treatment, they can last for over 15-20 years. In highly abrasive mining applications, a 3-5 year lifespan is common, which is still significantly longer than most alternative screen media.

5. Can a wedge wire screen be used for gas filtration?

Absolutely. While commonly used for liquid-solid separation, `wedge wire screens` are also effective for solid-gas separation. They are used as support grids for catalyst beds in reactors, as internals in gas scrubbers, and for filtering particulates from gas streams, offering high strength and temperature resistance.

6. What information is needed to get a quote for a custom wedge wire screen?

To provide an accurate quote for a custom wedge wire screen for sale, we need the following details: dimensions (diameter, length, width), required slot size, material of construction (e.g., SS316L), flow direction (e.g., FOTI - Flow Out to In), any required end fittings or frames, and a description of the application (fluid type, temperature, pressure, and particle characteristics).

7. How does a sieve bend screen work?

A `sieve bend screen` is a curved, static `wedge wire screen`. Slurry is fed tangentially onto the upper surface. As the slurry flows down the curve, the thin layer of water closest to the screen surface is "shaved" off through the slots due to the Coandă effect, while the solids continue down the screen surface. This makes it an incredibly efficient, low-energy dewatering device.

Conclusion & Authoritative References

Choosing the right wedge wire screen for sale is a critical decision that impacts operational efficiency, maintenance costs, and final product quality. From understanding the nuances of V-wire construction and precision welding to leveraging customization for specific industrial challenges, the wedge wire screen proves itself to be a superior technology. By partnering with a knowledgeable manufacturer like MUTO Screen, you gain access not only to a high-quality product but also to the expertise required to optimize your separation and filtration processes for years to come.

For further reading and industry standards, we recommend the following resources:

- Svarovsky, L. (2000). Solid-Liquid Separation. Butterworth-Heinemann. This text provides a fundamental understanding of the principles behind screen filtration.

- Water & Wastes Digest. (2021). "The Importance of Intake Screen Selection for Water Treatment Plants." www.wwdmag.com - A publication often featuring articles on filtration technology and best practices.

- American Society for Testing and Materials (ASTM) International. Standard A580/A580M - 20, "Standard Specification for Stainless Steel Wire." www.astm.org - The defining standard for the quality of stainless steel wire used in manufacturing.