- Overview of Parabolic Screen Technology in Wastewater Management

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Applications

- Real-World Case Studies and Operational Impact

- Future Trends in Filtration Systems

- Why Parabolic Screens Are Essential for Modern Wastewater Treatment

(parabolic screen wastewater)

Optimizing Wastewater Treatment with Parabolic Screen Technology

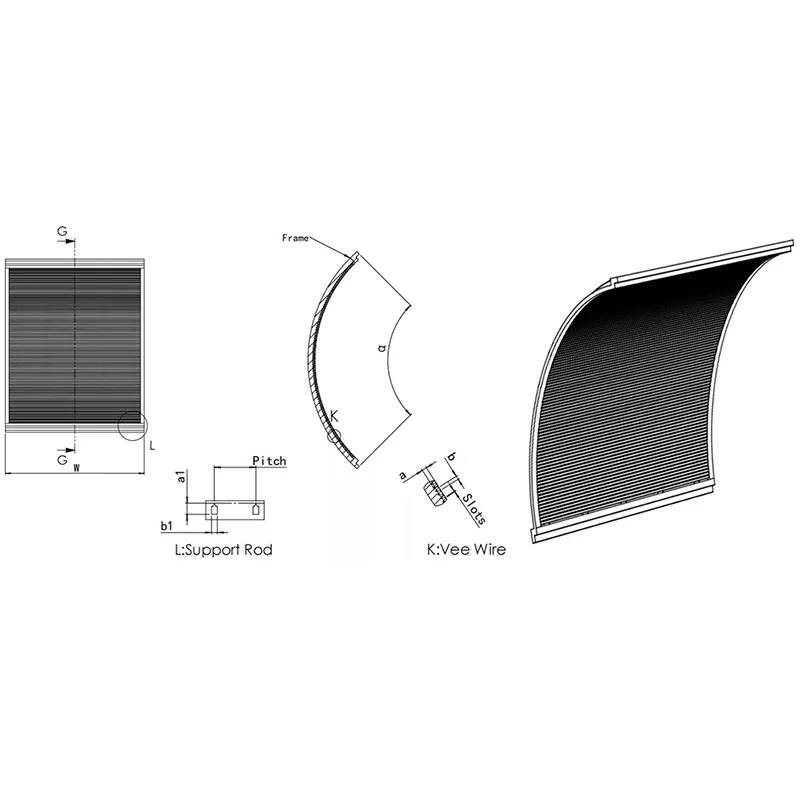

Parabolic screen systems have emerged as a critical innovation in wastewater management, addressing the escalating demand for efficient solid-liquid separation. These systems utilize a unique curved design to enhance flow dynamics, achieving up to 98% removal efficiency for suspended solids above 0.5mm. Industries ranging from municipal water plants to food processing facilities are adopting parabolic screens to reduce downstream equipment wear and operational costs.

Technical Advantages and Performance Metrics

Unlike traditional bar screens or drum filters, parabolic screens offer distinct benefits:

- 30-50% Higher Throughput: Curved geometry minimizes clogging, enabling continuous operation at 500–2,000 m³/h flow rates.

- Energy Savings: Reduced motor power (typically 1.5–5 kW) compared to vortex systems requiring 7–15 kW.

- Low Maintenance: Self-cleaning mechanisms extend service intervals to 6–12 months, cutting downtime by 40%.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Max Capacity (m³/h) | Screen Gap (mm) | Maintenance Cycle | Customization |

|---|---|---|---|---|

| EcoFilter Tech | 2,200 | 0.3–3.0 | 12 months | Material-grade options |

| HydroSep Solutions | 1,800 | 0.5–5.0 | 8 months | Variable curvature |

| AquaScreen Systems | 2,500 | 0.2–2.5 | 10 months | IoT integration |

Customization Options for Diverse Applications

Tailored parabolic screen configurations address specific challenges:

- Municipal Wastewater: 316L stainless steel screens with 0.6mm gaps for microplastic capture.

- Industrial Effluent: Abrasion-resistant polyurethane coatings extend lifespan in mining operations by 3×.

- Agricultural Runoff: Adjustable weir plates manage seasonal flow variations up to 300%.

Real-World Case Studies and Operational Impact

A dairy processing plant in Wisconsin implemented a parabolic screen filter, achieving:

- 72% reduction in BOD levels within 3 months

- Annual savings of $145,000 in pump maintenance

- 99.1% uptime since installation in 2022

Future Trends in Filtration Systems

Emerging innovations include AI-powered blockage prediction (reducing unplanned outages by 65%) and graphene-coated screens that resist biofouling for 18+ months. These advancements position parabolic screens as the backbone of next-generation circular water economies.

Securing Water Sustainability Through Parabolic Screen Wastewater Solutions

With global wastewater production projected to increase by 24% by 2030, parabolic screen technology delivers the scalability and reliability needed for sustainable water management. Facilities adopting these systems report 9–15 month ROI periods while meeting stringent EPA and EU Water Framework Directive standards.

(parabolic screen wastewater)

FAQS on parabolic screen wastewater

Q: What is the primary purpose of a parabolic screen in wastewater treatment?

A: A parabolic screen in wastewater treatment separates solids from liquids using its curved design, improving filtration efficiency. It handles high flow rates while minimizing clogging. This makes it ideal for municipal and industrial wastewater systems.

Q: How does a parabolic screen filter enhance wastewater processing?

A: A parabolic screen filter uses gravity and its curved surface to trap debris without mechanical parts, reducing energy consumption. Its self-cleaning design lowers maintenance needs. This ensures continuous, efficient wastewater treatment.

Q: What maintenance is required for a parabolic screen?

A: Parabolic screens require minimal maintenance due to their non-mechanical, self-cleaning operation. Periodic inspections for wear and debris buildup are recommended. Routine cleaning with water jets ensures long-term performance.

Q: Why choose a parabolic screen filter over traditional screening methods?

A: Parabolic screen filters outperform traditional methods with higher flow capacity and lower clogging risks. They eliminate the need for manual cleaning or frequent replacements. Their durability reduces operational costs over time.

Q: In which industries are parabolic screens commonly used?

A: Parabolic screens are widely used in municipal wastewater plants, food processing, and chemical manufacturing. They are also effective in agriculture and mining for solid-liquid separation. Their versatility suits high-volume, debris-heavy applications.