Polyurethane Slot Screen Plate - Muto Wire Screen Co., Ltd.|Industrial Sieving,Durable Filtration

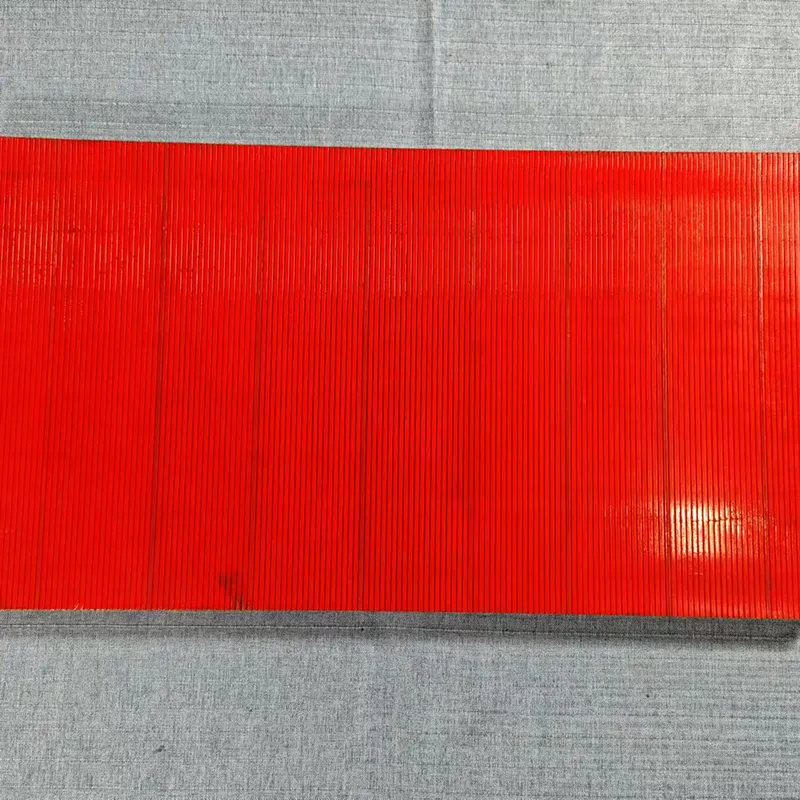

Polyurethane Slot Screen Plate: Durable and Efficient Solution for Industrial Sieving

At Muto Wire Screen Co., Ltd., we specialize in providing high-quality industrial sieving solutions. Our Polyurethane Slot Screen Plate is engineered to meet the demanding requirements of modern manufacturing processes. This article explores the features, benefits, and applications of our polyurethane screen plates, highlighting how they can enhance your production efficiency and reduce operational costs.

Understanding Polyurethane Slot Screen Plates

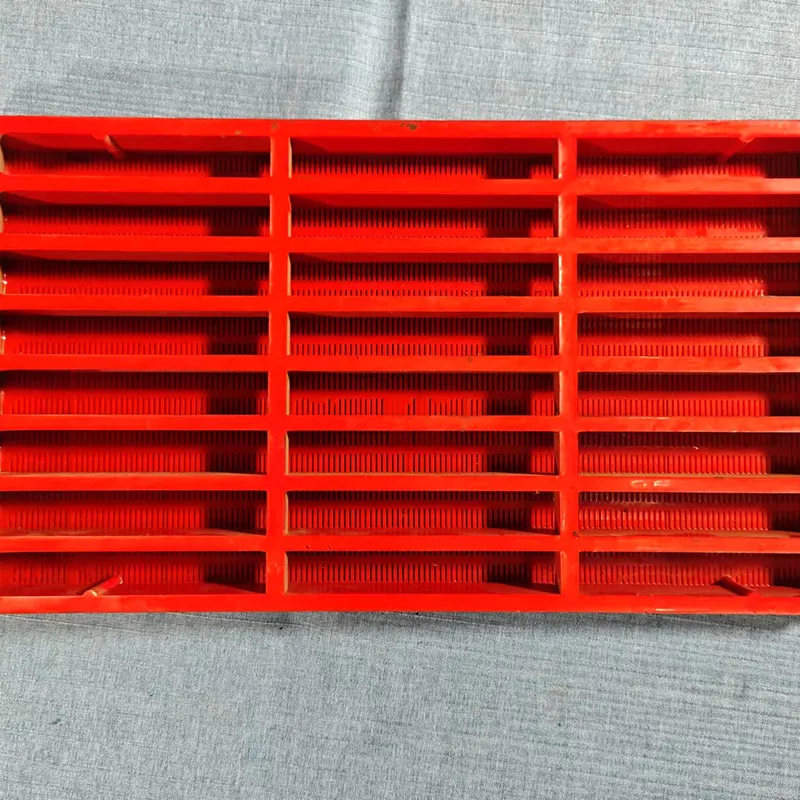

Polyurethane slot screen plates are specialized filtration components designed for industrial sieving applications. These plates are manufactured using advanced polyurethane materials, which offer exceptional durability, flexibility, and resistance to abrasion. The slot design allows for efficient material separation, making them ideal for use in industries such as mining, construction, and food processing.

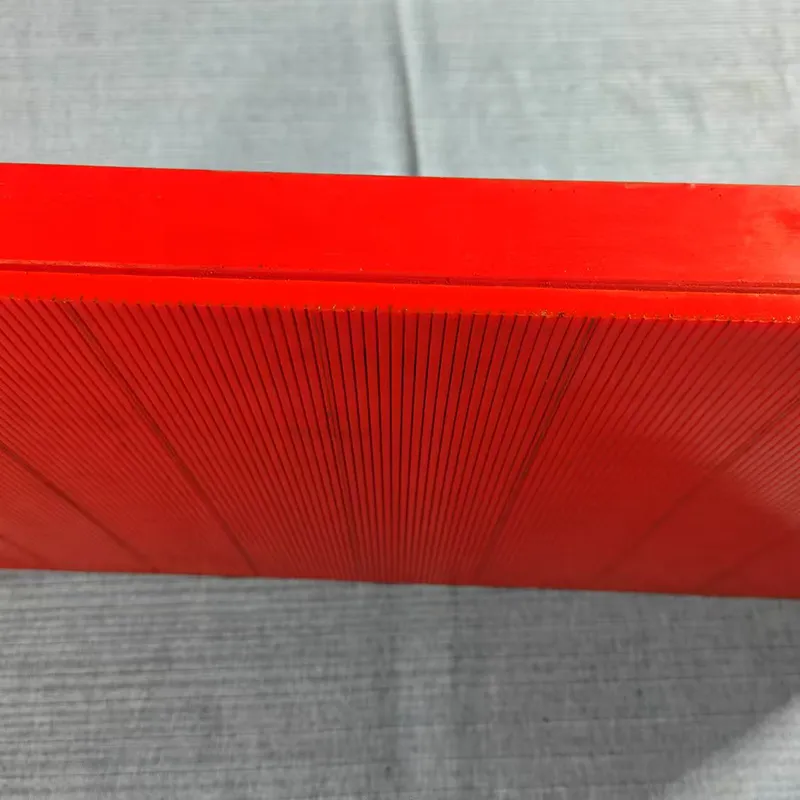

Unlike traditional metal screens, polyurethane slot plates are lightweight yet robust, capable of withstanding high-impact environments. Their unique structure ensures minimal material clogging, which translates to reduced downtime and maintenance costs. This makes them a preferred choice for industries seeking reliable and long-lasting sieving solutions.

Key Features and Technical Specifications

- Material Composition: High-performance polyurethane with enhanced wear resistance.

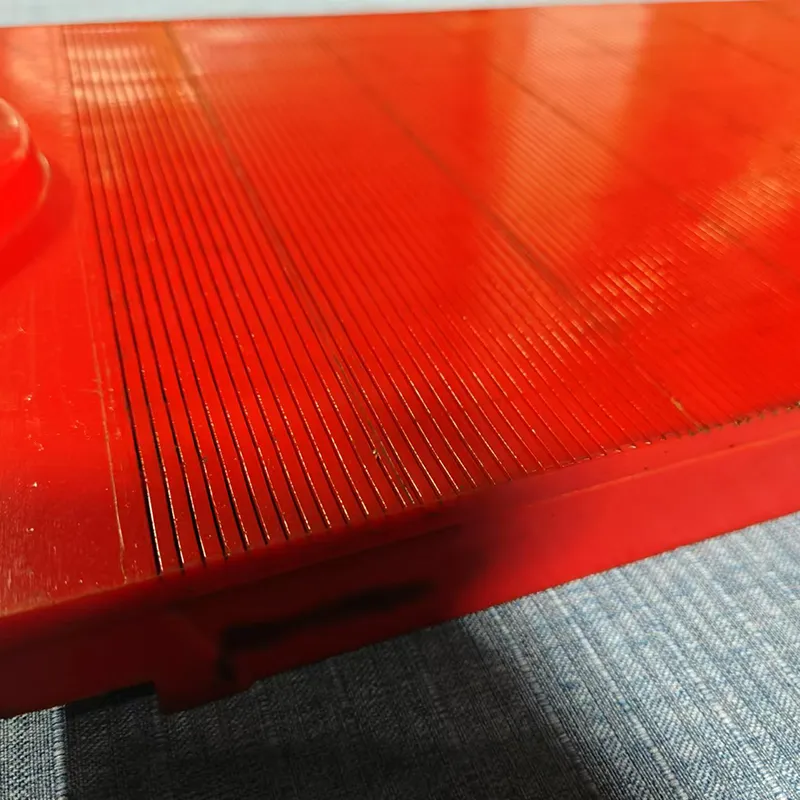

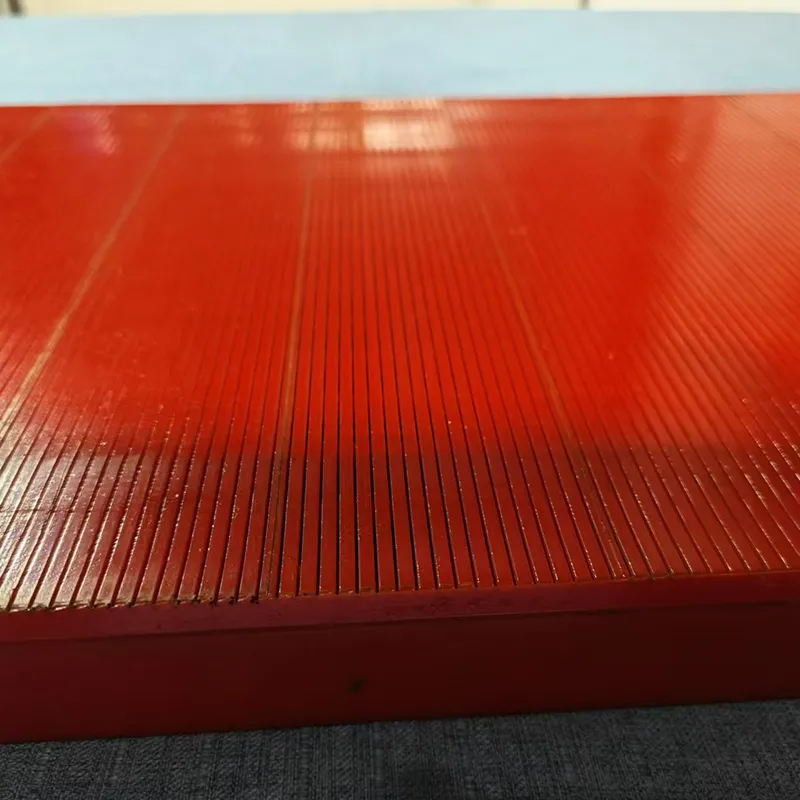

- Slot Design: Precision-engineered slots for optimal material flow and separation efficiency.

- Durability: Resists abrasion, chemicals, and extreme temperatures, ensuring a long service life.

- Flexibility: Can be customized to fit various screening equipment and industrial requirements.

- Lightweight: Easier to handle and install compared to traditional metal screens.

Our polyurethane slot screen plates are available in a range of thicknesses and slot widths to accommodate different screening needs. Whether you require fine particle separation or coarse material handling, our products are designed to deliver consistent performance. The advanced manufacturing process ensures uniformity in slot dimensions, minimizing the risk of material leakage or inefficiency.

Applications in Industrial Sieving

These polyurethane screens are widely used across various industries due to their versatility and reliability. Key applications include:

- Mineral Processing: Efficient separation of ore particles, reducing contamination and improving recovery rates.

- Construction Materials: Sieving of sand, gravel, and aggregates to ensure quality control.

- Food Processing: Safe and hygienic screening of ingredients, complying with food safety standards.

- Pharmaceuticals: Precise particle separation for drug formulation and packaging.

- Recycling: Sorting of waste materials to enhance recycling efficiency.

The adaptability of polyurethane slot screen plates makes them suitable for both dry and wet screening processes. Their resistance to corrosion and chemical degradation ensures they perform reliably even in harsh environments, such as those involving acidic or alkaline substances.

Addressing Industry Challenges

Traditional metal screens often face issues such as frequent wear, material clogging, and high maintenance costs. Our polyurethane solutions address these challenges by offering superior durability and reduced downtime. For example, in mining operations, where abrasive materials are common, polyurethane screens outlast conventional metal alternatives, significantly lowering replacement frequency and associated expenses.

Moreover, the flexibility of polyurethane allows the screens to absorb shocks and vibrations, reducing the risk of structural damage. This feature is particularly beneficial in high-speed screening applications where mechanical stress is a concern.

Company Background and Expertise

Muto Wire Screen Co., Ltd. (安平县慕图金属丝网制品有限公司) has been a trusted name in the industrial filtration industry for over a decade. With a focus on innovation and quality, we have established ourselves as a leading manufacturer of polyurethane screen plates and other industrial sieving solutions. Our state-of-the-art facilities and dedicated R&D team ensure that we stay at the forefront of technological advancements.

As a manufacturer, we understand the unique demands of different industries and tailor our products to meet these requirements. Our commitment to excellence is reflected in our ISO certifications and extensive customer base, which includes leading companies in mining, construction, and manufacturing sectors. By combining cutting-edge technology with customer-centric service, we deliver solutions that drive operational efficiency and cost savings.

Why Choose Polyurethane Slot Screen Plates?

There are several compelling reasons to opt for our polyurethane slot screen plates over traditional alternatives:

- Cost-Effectiveness: Reduced maintenance and replacement costs due to extended service life.

- Improved Efficiency: Enhanced screening performance with minimal material loss and clogging.

- Environmental Compliance: Non-toxic and recyclable materials, aligning with sustainable manufacturing practices.

- Customization: Flexible design options to suit specific industrial requirements.

Our products are not only designed for performance but also for sustainability. The use of polyurethane reduces the environmental impact of industrial sieving, making it an ideal choice for eco-conscious businesses.

Customer Testimonials and Success Stories

Our clients consistently praise the reliability and performance of our polyurethane slot screen plates. One of our long-term customers, a major mining company, reported a 40% reduction in screening downtime after switching to our products. Another user in the food processing industry highlighted the ease of cleaning and compliance with hygiene standards.

These success stories underscore the value our products bring to industries worldwide. By choosing Muto Wire Screen Co., Ltd., you gain access to a partner committed to your operational success.

Implementation and Support

Implementing our polyurethane slot screen plates is straightforward, with comprehensive support available from our team of experts. We provide detailed installation guides and on-site technical assistance to ensure seamless integration into your existing systems. Our customized solutions are designed to optimize performance for your specific applications.

For clients requiring specialized configurations, we offer tailored design services. Whether you need a unique slot size, thickness, or material composition, our engineers work closely with you to develop the perfect solution.

Environmental and Safety Standards

Safety and environmental responsibility are core to our manufacturing process. Our polyurethane screen plates are produced using non-toxic materials that meet international safety standards. They are free from harmful chemicals, ensuring a safe working environment for your employees.

In addition, our products are designed to minimize waste and energy consumption during operation. This commitment to sustainability aligns with global efforts to reduce the environmental footprint of industrial activities.

Packaging and Delivery

We ensure that our polyurethane slot screen plates are delivered in optimal condition, with robust packaging that protects against damage during transit. Our logistics partners are experienced in handling industrial goods, guaranteeing timely and secure delivery to your facility.

For bulk orders, we offer cost-effective packaging solutions that reduce transportation costs while maintaining product integrity. Our team works closely with you to plan the most efficient delivery schedule, minimizing disruptions to your operations.

After-Sales Support and Technical Assistance

At Muto Wire Screen Co., Ltd., we are committed to providing exceptional after-sales support. Our dedicated customer service team is available to address any inquiries or issues you may encounter. We offer technical consultations, on-site training, and warranty services to ensure your satisfaction.

Our goal is to build long-term partnerships with our clients, offering continuous support and innovation. Whether you need assistance with product installation, maintenance, or performance optimization, we are here to help.

Get in Touch with Muto Wire Screen Co., Ltd.

Ready to experience the benefits of our polyurethane slot screen plates? Contact us today to learn more about our products and how we can tailor solutions to meet your needs. Visit our company website to explore our full range of industrial sieving products or reach out to our sales team via phone at +86-138-0000-0000.

For immediate assistance, use our online inquiry form to request a quote or schedule a consultation. Let us help you achieve greater efficiency and cost savings in your industrial operations.

Frequently Asked Questions (FAQ)

1. What are the main advantages of polyurethane slot screen plates?

Polyurethane slot screen plates offer superior durability, resistance to abrasion, and reduced maintenance requirements compared to traditional metal screens. They are lightweight, flexible, and designed to minimize material clogging, enhancing overall efficiency.

2. Are these screens suitable for wet and dry applications?

Yes, our polyurethane slot screen plates are designed to perform effectively in both dry and wet screening environments. They are resistant to corrosion and chemical degradation, making them ideal for diverse industrial applications.

3. Can the screens be customized to specific requirements?

Yes, we offer customized solutions to meet your unique needs. Our engineers can design screens with specific slot sizes, thicknesses, and material compositions to optimize performance for your operations.

4. What kind of after-sales support do you provide?

We provide comprehensive after-sales support, including technical consultations, on-site training, and warranty services. Our team is available to assist with installation, maintenance, and performance optimization.

5. How long does the delivery take?

Delivery times vary depending on your location and order quantity. We work with reliable logistics partners to ensure timely and secure delivery. For specific timelines, please contact our sales team.

Conclusion

Our polyurethane slot screen plates are a reliable and cost-effective solution for industrial sieving applications. With their advanced design, durability, and environmental benefits, they help businesses improve efficiency and reduce operational costs. Contact Muto Wire Screen Co., Ltd. today to explore how our products can enhance your operations. Learn more about our polyurethane screens.