The Unseen Revolution: Why Polyurethane Screens Dominate Modern Screening Applications

In the demanding world of mineral processing, aggregates, recycling, and various industrial applications, efficient and reliable screening is paramount. Traditionally, steel screens were the go-to solution, but their limitations in terms of wear, noise, and blinding issues have paved the way for a superior alternative: polyurethane screens. These advanced screening media are transforming operations worldwide, offering unprecedented durability, performance, and cost-effectiveness. Our focus today is on understanding the comprehensive benefits of these screens, including specialized components like the Polyurethane Rail Seat For Vibrating Screen, crucial for maximizing the efficiency of any vibrating screen or banana screen.

Industry Trends and the Imperative for High-Performance Screening

The global mining and aggregates industries are facing increasing pressure to enhance productivity, reduce operational costs, and minimize environmental impact. This drives a continuous search for materials and technologies that can withstand harsh operating conditions while improving efficiency. Old-school wire mesh or punched plate screens, while initially cheaper, succumb quickly to abrasive materials, leading to frequent downtime for replacement, increased labor costs, and significant production losses. The emerging trend unequivocally points towards high-performance polymer solutions. Specifically, the adoption of polyurethane screens is skyrocketing due to their exceptional resilience to abrasion, impact, and chemical degradation. This material's inherent flexibility also provides a self-cleaning effect, significantly reducing pegging and blinding, which are common headaches in screening processes, especially with damp or sticky materials.

Furthermore, the demand for finer separation and higher throughput rates, particularly in specialized applications like banana screens designed for high-capacity dewatering or sizing, necessitates materials that can maintain their integrity and aperture accuracy over extended periods. Polyurethane's mouldable nature allows for precise aperture designs, enhancing screening accuracy and overall plant performance. The integration of components like the Polyurethane Rail Seat For Vibrating Screen ensures a secure and durable attachment of these screening media to the main screening deck, further amplifying their performance benefits.

Unpacking the Technical Superiority of Polyurethane Screens

The core of polyurethane's success lies in its unique material properties. Polyurethane is an elastomeric polymer that can be engineered with varying degrees of hardness, flexibility, and resistance to environmental factors. Unlike metals, which are rigid and prone to fatigue and corrosion, polyurethane absorbs impact, resists wear from abrasive particles, and can withstand exposure to various chemicals, oils, and moisture.

Key Performance Indicators (KPIs) and Advantages:

- Superior Abrasion Resistance: Polyurethane far outperforms steel in resisting abrasive wear. In typical aggregate screening, polyurethane screens can last 3-10 times longer than wire mesh, significantly reducing replacement frequency and maintenance costs.

- Noise Reduction: The elastic nature of polyurethane significantly dampens noise generated by material impact, contributing to a safer and more compliant working environment. Noise levels can be reduced by as much as 8-10 dB compared to steel screens.

- Reduced Blinding and Pegging: The flexibility and tapered apertures of polyurethane panels, especially when combined with a specific vibrating screen action, minimize the accumulation of near-size particles, maintaining open areas and maximizing screening efficiency.

- Corrosion Resistance: Polyurethane is inherently resistant to rust and many chemical corrosives, making it ideal for wet screening applications or environments with high humidity or chemical exposure, common in mining or chemical processing.

- Lighter Weight: Compared to steel, polyurethane panels are considerably lighter, simplifying installation, reducing structural load on the screen machine, and improving safety during handling.

- Impact Absorption: Polyurethane's elastic properties allow it to absorb impact energy from large falling particles, protecting both the screen media and the vibrating screen structure from damage.

Polyurethane vs. Steel Screens: A Performance Snapshot

| Feature | Polyurethane Screens | Steel Wire Mesh / Punched Plate | Advantage of Polyurethane |

|---|---|---|---|

| Wear Life | Excellent (3x-10x longer) | Moderate to Poor | Significantly Extended |

| Abrasion Resistance | Superior | Low to Moderate | Excellent |

| Noise Level | Low (Vibration Dampening) | High | Substantial Reduction |

| Blinding/Pegging | Minimal (Self-cleaning) | Frequent | Greatly Reduced Downtime |

| Impact Resistance | High (Elasticity) | Low (Brittle) | Superior Protection |

| Weight | Lightweight | Heavy | Easier Handling & Installation |

| Maintenance Frequency | Very Low | High | Dramatic Reduction |

| Corrosion Resistance | Excellent | Poor (Rusts) | Full Resistance |

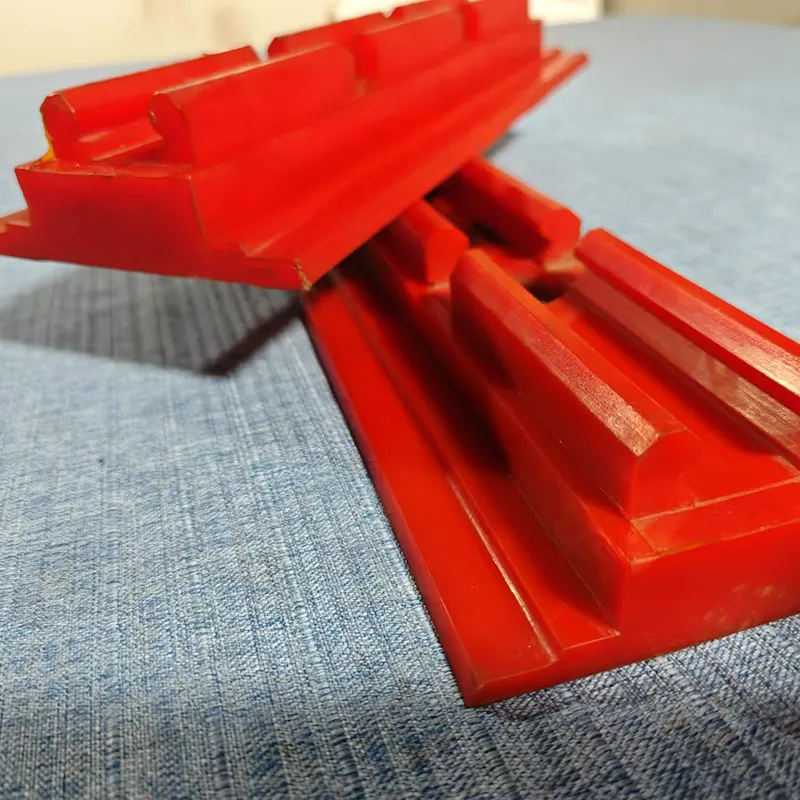

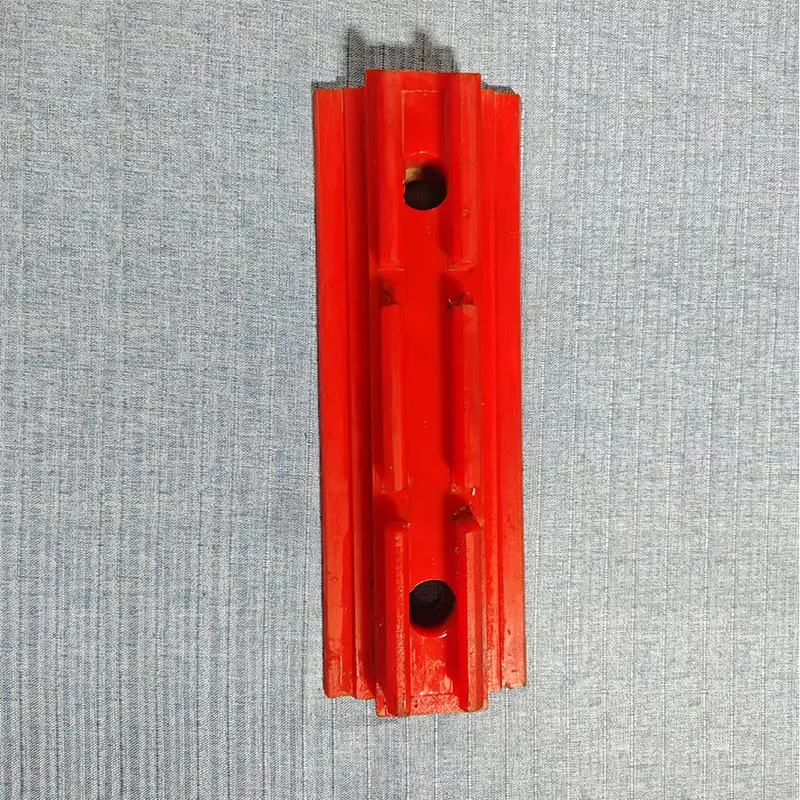

Product Spotlight: Polyurethane Rail Seat For Vibrating Screen

While the polyurethane screens themselves are the stars, their efficacy is deeply reliant on the components that integrate them into the screening machine. The Polyurethane Rail Seat For Vibrating Screen is a critical, yet often overlooked, element that ensures the secure, stable, and long-lasting installation of screen panels. This product, found at https://www.mutoscreen.com/polyurethane-rail-seat-for-vibrating-screen.html, plays a pivotal role in optimizing the performance and lifespan of the entire screening deck.

The Meticulous Manufacturing Process of Polyurethane Screening Components

The production of high-quality polyurethane screens and their ancillary components like rail seats is a sophisticated process demanding precision and expertise. Here's a detailed look into the typical manufacturing workflow:

- Material Selection & Preparation: The journey begins with selecting premium-grade polyurethane elastomers, often a blend of prepolymers, polyols, and curative agents. These raw materials are chosen based on the desired final properties, such as hardness (Shore A/D), tear strength, abrasion resistance, and temperature range. For the Polyurethane Rail Seat, emphasis is placed on high compression set resistance and excellent adhesion properties if it's bonded to metal.

- Precision Mold Design & Fabrication: Highly durable and precisely engineered molds, typically made from steel or aluminum, are designed using CAD software. These molds dictate the final dimensions, shape, and surface finish of the polyurethane part. For complex profiles like screen panels or rail seats, multi-part molds are often used to ensure intricate details are captured accurately.

- Mixing & Degassing: The liquid polyurethane components are carefully measured and mixed according to a precise formula. This mixing process is often carried out under vacuum conditions to eliminate air bubbles (degassing), which can compromise the material's structural integrity and performance. This step is crucial for achieving a uniform, defect-free product.

- Casting/Pouring: The degassed liquid polyurethane mixture is then poured or injected into the preheated molds. For the Polyurethane Rail Seat, this might involve casting directly onto a steel insert or a bonding surface to create a composite part. The preheating of molds ensures optimal flow and adhesion.

- Curing & Post-Curing: Once cast, the polyurethane undergoes a curing process, often at elevated temperatures in specialized ovens. This initiates the polymerization reaction, transforming the liquid mixture into a solid elastomer. A subsequent post-curing phase might be required for several hours or days to achieve the material's full physical properties, ensuring maximum hardness, strength, and durability. This controlled thermal process is vital for dimensional stability and long-term performance, adhering to standards like ASTM D2240 for hardness testing.

- Demolding & Finishing: After curing, the parts are carefully demolded. Excess material (flash) is trimmed, and components may undergo additional finishing processes such as grinding, deburring, or drilling to meet exact specifications and ensure smooth, clean edges.

- Quality Control & Inspection: Rigorous quality control is paramount at every stage. Finished products, including the Polyurethane Rail Seat, undergo a battery of tests:

- Dimensional Inspection: Using calipers, gauges, and laser scanners to ensure compliance with engineering drawings (e.g., ISO 2768-1 for general tolerances).

- Hardness Testing: Measuring Shore A or Shore D hardness to confirm material consistency (e.g., ASTM D2240, ISO 7619).

- Visual Inspection: Checking for surface defects, air bubbles, or inconsistencies.

- Performance Testing: For screen panels, this might involve abrasion resistance tests (e.g., DIN 53516) or tensile strength tests (e.g., ASTM D412). For rail seats, load-bearing tests or compression set tests are vital.

- Packaging & Shipping: Finally, the finished products are carefully packaged to prevent damage during transit and dispatched to clients worldwide.

This intricate process ensures that each Polyurethane Rail Seat For Vibrating Screen delivers exceptional performance, reliability, and an extended service life, typically exceeding that of traditional materials by severalfold, often lasting 3-5 years or more under demanding conditions. These components are specifically designed for industries such as mining (coal, iron ore, copper), aggregates (crushed stone, sand & gravel), metallurgy, chemical processing, and even recycling plants where corrosive environments or high abrasion are prevalent.

Application Scenarios and Real-World Impact (Experience)

The versatility of polyurethane screens allows them to excel across a multitude of industries and applications. Their unique properties address critical pain points, leading to significant operational improvements.

Key Application Industries:

- Mining & Minerals Processing: From iron ore and coal to copper and gold, polyurethane panels are used for sizing, scalping, dewatering, and desliming across primary, secondary, and tertiary screening stages. Their abrasion resistance is invaluable in handling highly abrasive ore.

- Aggregates & Quarrying: In the production of crushed stone, sand, and gravel, polyurethane screens handle abrasive rocks and provide precise sizing for construction materials. They are particularly effective in wet screening applications.

- Chemical Processing: Where corrosive liquids or abrasive slurries are present, polyurethane's chemical resistance makes it a preferred choice for separation and dewatering processes.

- Recycling: Sorting and separating various waste materials, including C&D (construction and demolition) debris, requires robust and resilient screening media that can withstand impact and irregular shapes.

- Fertilizer Production: Screening of granular fertilizers, often involving corrosive elements, benefits greatly from polyurethane's durability and chemical inertness.

Benefits in Typical Screening Systems:

- Vibrating Screens: Whether it's a linear vibrating screen, circular, or high-frequency screen, polyurethane screens provide a robust, long-lasting screening surface. The Polyurethane Rail Seat ensures that these panels are securely fastened, withstanding intense vibrations and preventing premature wear at the mounting points. This synergy enhances the overall stability and efficiency of the screening deck.

- Banana Screens: Known for their high-capacity and efficient dewatering capabilities, banana screens greatly benefit from polyurethane's self-cleaning properties and high wear resistance. The changing angles of the deck on a banana screen maximize stratification and throughput, and polyurethane panels are ideally suited to maintain efficiency in this dynamic environment.

Client Success Story: Reducing Downtime in a Coal Washing Plant

A major coal washing plant in South Africa faced persistent challenges with premature wear and frequent blinding of their traditional wire mesh screens on their primary vibrating screens, leading to an average of 12 hours of unscheduled downtime per month for screen changes. After consulting with MutuScreen and implementing our custom polyurethane screens combined with Polyurethane Rail Seats, the plant observed a dramatic improvement. The service life of the screening media extended from 3 months to over 18 months, reducing screen change downtime by over 80%. Furthermore, the self-cleaning effect of the polyurethane virtually eliminated blinding, leading to a consistent 5% increase in throughput. This case exemplifies the tangible benefits of investing in high-quality polyurethane screening solutions, translating directly into enhanced productivity and significant cost savings over time.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

When investing in polyurethane screens and related components like the Polyurethane Rail Seat For Vibrating Screen, the choice of manufacturer is as critical as the product itself. Not all polyurethane products are created equal. Key differentiators include material quality, manufacturing precision, R&D capabilities, and commitment to customer support.

Why MutuScreen Stands Out:

- Uncompromising Quality Control: At MutuScreen, our commitment to quality is ingrained in every step of the manufacturing process, from raw material sourcing (ensuring compliance with international standards) to final inspection. Our internal testing procedures often exceed industry benchmarks.

- Expertise and R&D: With years of dedicated research and development in polyurethane technology, our engineers possess deep knowledge of material science and application demands. This allows us to innovate and tailor solutions for the most challenging screening environments. We understand the nuances of various vibrating screen types, including banana screens and different screening deck configurations.

- Customization Capabilities: We recognize that every operation has unique requirements. MutuScreen excels in providing bespoke solutions. Whether it's specific aperture sizes and shapes, panel dimensions, different polyurethane hardness (Shore A 30 to Shore D 70) to handle varying material types (e.g., fine powders vs. coarse aggregates), or unique fastening systems for the Polyurethane Rail Seat, our engineering team works closely with clients to design optimal solutions. We can adapt to existing screen frames and design new ones for enhanced performance.

- Global Service and Support: Our dedicated after-sales support team provides technical assistance, installation guidance, and troubleshooting to ensure maximum uptime for our clients worldwide.

Building Trust: Certifications, Warranty & Support (Authoritativeness & Trustworthiness)

Our commitment to excellence is underpinned by rigorous standards and a client-first approach. MutuScreen operates under a stringent quality management system, ensuring consistency and reliability across our product range, including our acclaimed polyurethane screens and the Polyurethane Rail Seat For Vibrating Screen.

Industry Certifications & Partnerships:

MutuScreen is proud to be ISO 9001:2015 certified, affirming our adherence to internationally recognized quality management principles. This certification is a testament to our robust processes for design, development, production, installation, and service. We maintain strong partnerships with leading research institutions and material suppliers to stay at the forefront of polyurethane technology, ensuring our products, from vibrating screen panels to specialized screening deck components, are always of the highest standard.

Transparent Policies & Customer Support:

Quality Assurance & Warranty:

We stand behind the quality of our polyurethane screens and all related products. MutuScreen offers a comprehensive warranty against manufacturing defects and premature wear under normal operating conditions. Specific warranty periods and terms are provided with each quotation and product delivery, reflecting our confidence in our products' durability and performance. Our products undergo third-party testing for key properties such as abrasion resistance (e.g., per ASTM G65) and tensile strength (e.g., per ISO 37), with data available upon request to substantiate claims of superior performance.

Delivery Cycle:

Understanding the critical nature of lead times in industrial operations, MutuScreen employs efficient manufacturing processes and robust supply chain management. Standard products typically have a delivery cycle of 3-4 weeks from order confirmation, while custom solutions may require slightly longer depending on complexity. We work closely with clients to meet urgent deadlines where possible, ensuring minimal disruption to their operations.

Comprehensive Customer Support:

Our commitment extends beyond product delivery. MutuScreen provides ongoing technical support, including assistance with product selection, installation guidance, and troubleshooting. Our global network of service professionals is accessible via multiple channels—phone, email, and online support—to ensure prompt and effective resolution of any queries or challenges. We believe in building long-term partnerships based on mutual trust and sustained performance.

Data Insights: Typical Polyurethane Screen Parameters

To provide a clear understanding of the technical specifications and capabilities of polyurethane screens, the following table outlines typical parameters that manufacturers aim for and that users can expect from high-quality products. These values can vary based on the specific formulation and application requirements (e.g., fine screening vs. heavy scalping).

| Property | Typical Range | Measurement Standard (Example) | Significance in Application |

|---|---|---|---|

| Hardness (Shore A) | 60A - 95A | ASTM D2240 / ISO 7619 | Resistance to indentation, influences wear life and blinding. Higher A for general screens, lower A for flexibility/self-cleaning. |

| Hardness (Shore D) | 40D - 70D | ASTM D2240 / ISO 7619 | For rigid sections like rail seats or thicker panel backings. Higher D indicates greater stiffness. |

| Tensile Strength | 30 - 60 MPa | ASTM D412 / ISO 37 | Resistance to breaking under tension; critical for panel integrity under vibration. |

| Elongation at Break | 300% - 600% | ASTM D412 / ISO 37 | Ability to stretch before breaking; indicates flexibility and impact absorption. |

| Tear Strength | 60 - 150 kN/m | ASTM D624 / ISO 34 | Resistance to tearing when notched; important for panel edges and fastening points. |

| Abrasion Loss (Volumetric) | DIN 53516 (with 10mg loss steel reference) | Indicates wear resistance; lower value means better wear performance against abrasive materials. | |

| Temperature Range (Continuous) | -30°C to +80°C | Manufacturer Specific | Operating temperature limits without degradation of properties. |

| Specific Gravity | 1.15 - 1.25 g/cm³ | ASTM D792 | Lightweight nature compared to steel (approx. 1/7th the density). |

| Typical Mesh/Aperture Sizes | 0.1 mm to 150 mm | Custom / Industry Standard | Highly customizable to precise separation needs. |

| Panel Dimensions | Up to 1.5m x 3.0m (Modular) | Custom / Industry Standard | Modular design allows for easy replacement and scalability for various screening deck sizes. |

| Expected Lifespan | 12 - 60 months | Application Dependent | Significantly longer than traditional materials, reducing replacement frequency. |

Frequently Asked Questions (FAQ) about Polyurethane Screens

1. What are polyurethane screens made of?

Polyurethane screens are made from high-grade polyurethane elastomers, which are polymers composed of organic units joined by carbamate (urethane) links. These materials are chosen for their exceptional abrasion resistance, elasticity, and chemical inertness, making them ideal for heavy-duty screening applications.

2. What are the main advantages of polyurethane over steel screens?

Polyurethane offers several key advantages: significantly longer wear life (3-10 times), substantial noise reduction, minimal blinding/pegging due to its flexible, self-cleaning nature, superior impact absorption, corrosion resistance, and lighter weight for easier handling and installation. These benefits lead to reduced downtime and lower operational costs.

3. How long do polyurethane screens typically last?

The lifespan of polyurethane screens varies depending on the specific application, material being screened, and operating conditions. However, under typical abrasive conditions, they can last anywhere from 12 months to 5 years or even longer, significantly outperforming traditional steel screens.

4. Can polyurethane screens be customized for specific applications?

Absolutely. Reputable manufacturers like MutuScreen offer extensive customization options. This includes varying aperture sizes (from fine mesh to large openings), different panel dimensions and configurations, a range of polyurethane hardness (Shore A or D) to suit material characteristics, and specialized designs for unique vibrating screen types or screening deck setups.

5. What are banana screens and how do polyurethane panels benefit them?

Banana screens are multi-slope vibrating screens designed for high-capacity and efficient separation, particularly in dewatering or fine sizing. Polyurethane screens greatly benefit banana screen performance due to their high abrasion resistance, ability to maintain precise apertures for accurate sizing, and their self-cleaning properties which prevent blinding even with high moisture content materials, ensuring continuous high throughput.

6. How is the Polyurethane Rail Seat For Vibrating Screen installed?

The Polyurethane Rail Seat For Vibrating Screen is designed for secure and efficient installation. It typically slots into or is bolted onto the main frame of the vibrating screen, providing a stable and durable base for the polyurethane screen panels. Its design ensures proper tensioning and support for the screen media, preventing premature wear and maintaining panel integrity under intense vibration.

7. What maintenance is required for polyurethane screens?

One of the significant advantages of polyurethane screens is their minimal maintenance requirements. Unlike steel screens that frequently need cleaning or replacement, polyurethane's self-cleaning properties reduce blinding, and its extended wear life means less frequent changes. Routine visual inspections for wear and tear, and ensuring proper tensioning (if applicable) are generally sufficient. The Polyurethane Rail Seat also contributes to reduced maintenance by providing a stable and long-lasting support structure.

Optimize Your Operations with MutuScreen Polyurethane Solutions

Ready to revolutionize your screening process? Experience the unparalleled durability, efficiency, and cost-effectiveness of MutuScreen's polyurethane screens and the essential Polyurethane Rail Seat For Vibrating Screen. Our expert team is here to provide tailored solutions that meet your specific operational needs, ensuring maximum uptime and profitability.

Discover Our Polyurethane Rail SeatReferences and Further Reading

- "Advances in Screening Technology for Mineral Processing" - Journal of Minerals Engineering, Volume 12, Issue 3, 2022. https://www.sciencedirect.com/journal/minerals-engineering

- "Polyurethane in Mining Applications: A Review" - International Journal of Mining Science and Technology, Volume 31, Issue 5, 2021. https://www.sciencedirect.com/journal/international-journal-of-mining-science-and-technology

- "Understanding Material Properties for Optimal Screen Media Selection" - Aggregates Manager Magazine, 2023. https://www.aggregatesmanager.com/