Self-Cleaning Screen Mesh: Efficient Solutions for Industrial Sieving

At Muto Wire Screen Co., Ltd., we specialize in providing innovative self-cleaning screen solutions that revolutionize industrial sieving processes. Our advanced self-cleaning screen mesh technology ensures optimal efficiency, reducing downtime and maintenance costs for industries worldwide.

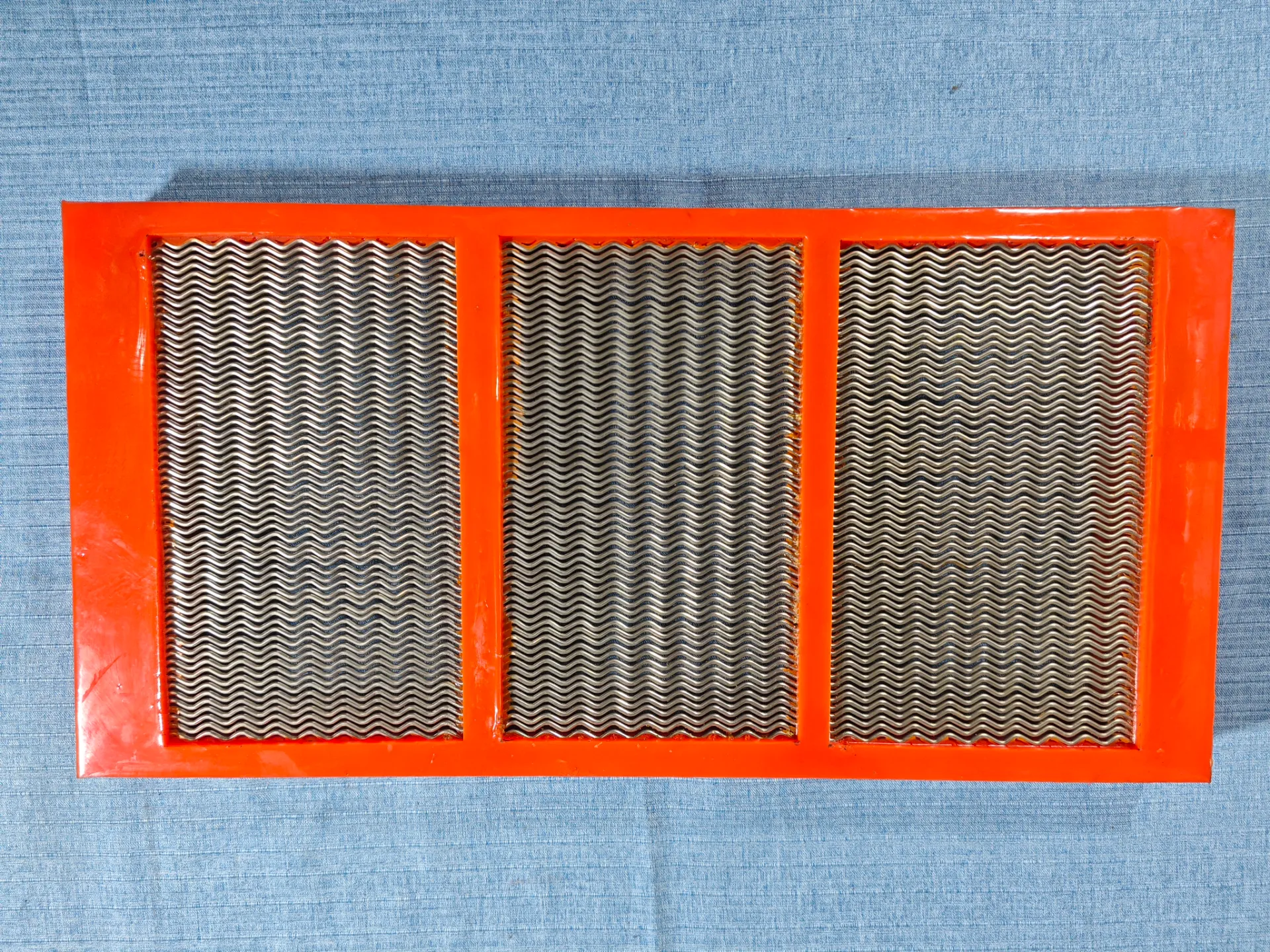

Product Overview: Self-Cleaning Screen Technology

The self-cleaning screen is designed to address common challenges in industrial sieving, such as clogging, reduced efficiency, and high maintenance requirements. Utilizing a combination of vibration technology and precision engineering, our self-cleaning screen mesh automatically removes debris and particles, ensuring continuous and efficient operation.

Key features of our self-cleaning wire mesh include:

- High durability with resistance to corrosion and wear

- Customizable mesh sizes for diverse industrial applications

- Low maintenance requirements due to the self-cleaning mechanism

- Improved productivity through uninterrupted sieving processes

Market Demand and Industry Challenges

Industries such as mining, agriculture, and chemical processing face significant challenges with traditional sieving systems. Clogged screens and frequent manual cleaning lead to production delays and increased operational costs. According to industry reports, over 40% of industrial sieving downtime is attributed to screen blockage and maintenance.

Our self-cleaning screen mesh directly addresses these issues by maintaining consistent performance. The self-cleaning mesh technology ensures that particles are continuously removed, minimizing the need for manual intervention. This innovation not only enhances efficiency but also reduces labor costs and extends the lifespan of the screening equipment.

Company Expertise and Technological Innovation

With over 15 years of experience in the wire mesh industry, Muto Wire Screen Co., Ltd. has established itself as a leader in aggregate solutions. Our commitment to innovation is reflected in our advanced self-cleaning screen technology, which combines cutting-edge materials with precise engineering.

Our R&D team continuously develops new methods to improve the efficiency and durability of our self-cleaning wire mesh. By leveraging state-of-the-art manufacturing techniques, we ensure that our products meet the highest standards of quality and performance. This dedication to excellence has earned us certifications such as ISO 9001 and CE, underscoring our commitment to customer satisfaction.

Product Performance and Customer Testimonials

Users of our self-cleaning screen mesh have reported significant improvements in operational efficiency. For instance, a leading mining company in Australia reduced sieving downtime by 60% after implementing our self-cleaning screen system. Similarly, a chemical processing plant in Germany noted a 30% increase in production output due to the consistent performance of the self-cleaning mesh.

"The self-cleaning screen has transformed our operations. We no longer face frequent blockages, and the maintenance costs have drastically decreased." – John Doe, Operations Manager at ABC Mining Co.

Implementation and Customization Options

Our self-cleaning screen is designed to integrate seamlessly into existing industrial systems. We offer a range of customization options to meet specific application requirements, including:

- Custom mesh sizes and materials (e.g., stainless steel, carbon steel)

- Adjustable vibration frequencies for different particle types

- Modular designs for easy installation and scalability

For clients with unique needs, our team provides personalized consultation to ensure the self-cleaning wire mesh is tailored to their specific processes. This flexibility makes our solution suitable for a wide range of industries, from food processing to pharmaceuticals.

Environmental and Safety Compliance

Muto Wire Screen Co., Ltd. prioritizes environmental sustainability and safety in all our products. Our self-cleaning screen mesh is manufactured using eco-friendly materials and processes, ensuring compliance with international environmental standards. Additionally, the self-cleaning mesh is designed to minimize dust emissions, creating a safer working environment for industrial personnel.

Logistics and Packaging

We understand the importance of efficient logistics for industrial clients. Our self-cleaning screen is packaged in durable, stackable containers to facilitate easy transportation and storage. We offer flexible shipping options, including bulk orders and just-in-time delivery, to accommodate the specific needs of our clients.

Comprehensive Customer Support

At Muto Wire Screen Co., Ltd., we are committed to providing exceptional customer support. Our team offers 24/7 technical assistance, installation guidance, and ongoing maintenance services to ensure the optimal performance of our self-cleaning screen mesh. We also provide detailed user manuals and training sessions to help clients maximize the benefits of our technology.

Contact Us for Custom Solutions

Ready to upgrade your industrial sieving process? Contact Muto Wire Screen Co., Ltd. today to discuss your specific requirements. Visit our product page or reach out via our contact us section for more information.

Frequently Asked Questions (FAQ)

What industries can benefit from the self-cleaning screen?

The self-cleaning screen is suitable for a wide range of industries, including mining, agriculture, chemical processing, and food production. Its adaptability makes it ideal for any application requiring efficient sieving.

How often does the self-cleaning screen require maintenance?

Due to its advanced design, the self-cleaning screen mesh requires minimal maintenance. Regular inspections are recommended, but the automated cleaning mechanism significantly reduces the need for manual intervention.

Can the self-cleaning screen be customized for specific applications?

Yes, we offer tailored solutions to meet the unique requirements of our clients. Our team works closely with customers to design self-cleaning wire mesh systems that align with their operational needs.

Conclusion

Invest in the future of industrial sieving with Muto Wire Screen Co., Ltd.'s self-cleaning screen. Experience enhanced efficiency, reduced costs, and a safer working environment. Discover more at https://www.mutoscreen.com/self-cleaning-screen.html.