Self-Cleaning Screen-Muto Wire Screen Co., Ltd.|advanced filtration solutions&automatic cleaning technology

Self-Cleaning Screen: Advanced Filtration Solutions for Industrial Efficiency

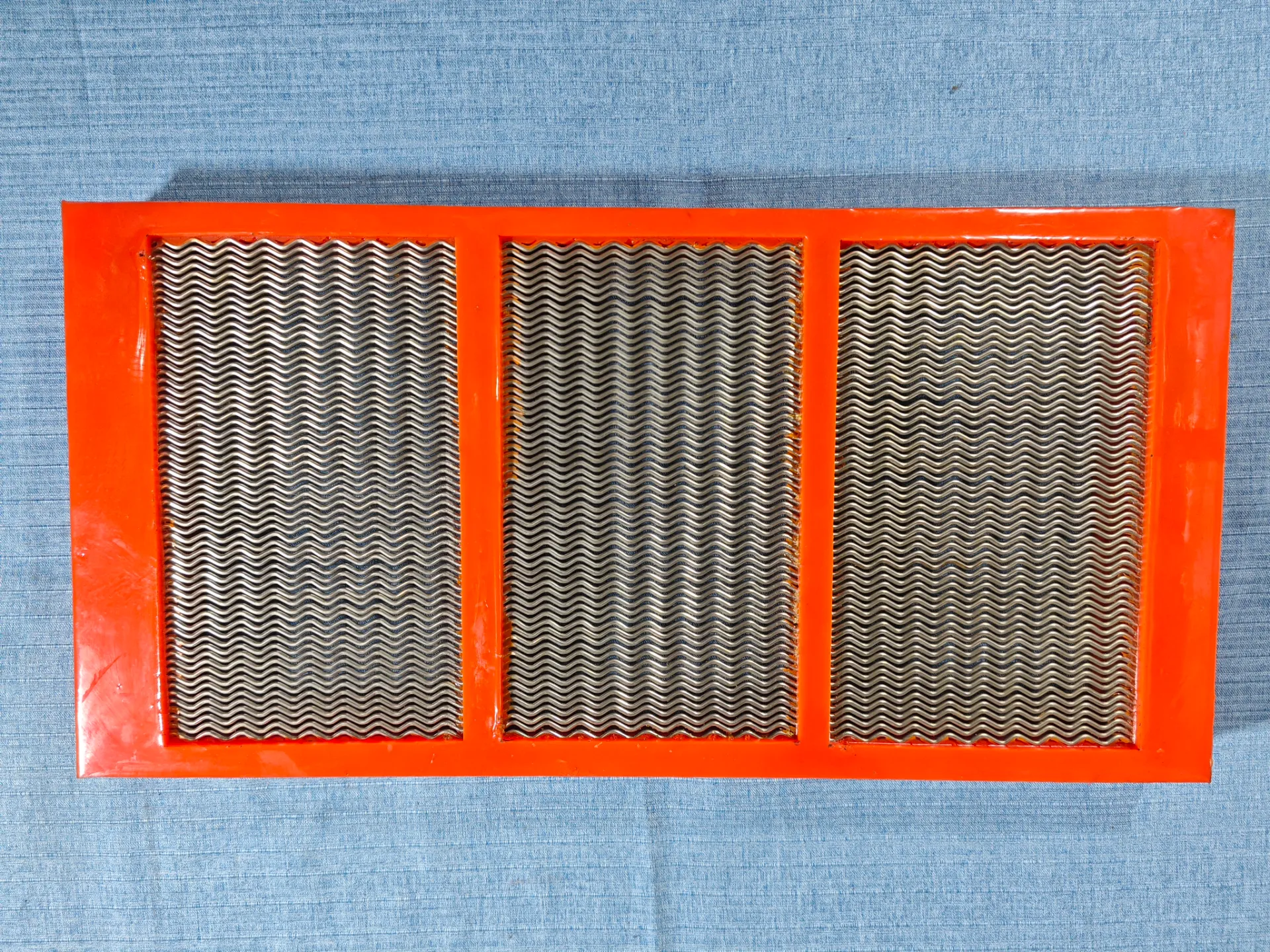

At Muto Wire Screen Co., Ltd., we specialize in providing innovative filtration solutions that address the evolving needs of modern industries. Our Self-Cleaning Screen is a prime example of our commitment to quality, efficiency, and sustainability. Designed to revolutionize the filtration process, this advanced technology eliminates the need for manual cleaning, reduces downtime, and enhances operational productivity. Whether you're in the mining, construction, or chemical industry, our self-cleaning screen offers a reliable and cost-effective solution to meet your specific requirements.

Understanding the Self-Cleaning Screen: A Game-Changer in Filtration Technology

The Self-Cleaning Screen is a cutting-edge filtration system engineered to maintain optimal performance with minimal human intervention. Unlike traditional screening methods that require frequent manual cleaning, our self-cleaning technology uses a combination of mechanical and hydraulic systems to automatically remove debris and clogging particles. This ensures continuous operation, reduces maintenance costs, and prolongs the lifespan of the screen.

Key features of the Self-Cleaning Screen include:

- Automatic Cleaning Mechanism: Utilizes rotating brushes or backwashing systems to clear clogged particles without shutting down the process.

- High Efficiency: Maintains consistent flow rates and filtration accuracy, even under heavy load conditions.

- Durability: Constructed with high-quality materials like stainless steel or corrosion-resistant alloys to withstand harsh industrial environments.

- Customizable Design: Tailored to fit specific application requirements, including mesh size, screen dimensions, and flow rates.

Addressing Industry Challenges: Why Self-Cleaning Screens Are Essential

The modern industrial landscape faces numerous challenges, including the need for energy-efficient processes, reduced labor costs, and compliance with environmental regulations. Traditional screening systems often fall short in these areas, leading to frequent downtime, higher operational costs, and suboptimal performance. Our Self-Cleaning Screen directly addresses these pain points by offering a smarter, more sustainable solution.

For example, in the aggregate industry, where large volumes of materials are processed, clogging is a common issue that disrupts production. Our self-cleaning technology ensures uninterrupted operation, while in the chemical industry, it maintains precise filtration standards to prevent contamination. By eliminating the need for manual cleaning, our product also reduces the risk of workplace injuries and lowers labor expenses.

Company Expertise: Muto Wire Screen Co., Ltd. – Pioneers in Filtration Innovation

With over two decades of experience in the wire mesh and filtration industry, Muto Wire Screen Co., Ltd. has established itself as a leader in developing advanced screening solutions. Our team of engineers and technicians continuously invests in research and development to create products that meet the highest standards of quality and performance. The Self-Cleaning Screen is a testament to our dedication to innovation and customer satisfaction.

Our state-of-the-art manufacturing facilities are equipped with precision machinery and quality control systems to ensure that every product meets exacting specifications. We also offer customized solutions tailored to the unique needs of our clients, whether they require a specific mesh size, material type, or design configuration.

Proven Results: Real-World Applications and Customer Testimonials

Our Self-Cleaning Screen has been successfully implemented across various industries, delivering measurable improvements in efficiency and cost savings. For instance, a leading mining company reported a 40% reduction in downtime after integrating our technology into their processing line. Similarly, a chemical manufacturer noted a significant decrease in maintenance costs and an increase in product quality due to the screen's consistent performance.

Customer feedback highlights the benefits of our product:

"The Self-Cleaning Screen has transformed our filtration process. It’s reliable, easy to maintain, and has saved us a lot of time and money." – John D., Production Manager, Mining Industry

"We were impressed by the customization options and the support from Muto Wire Screen. The screen performs flawlessly even under demanding conditions." – Emily R., Operations Director, Chemical Industry

How to Use the Self-Cleaning Screen: Step-by-Step Guide

Implementing the Self-Cleaning Screen requires careful planning to ensure optimal performance. Here’s a simplified guide to help you get started:

- Assess Your Needs: Determine the specific application requirements, including material type, flow rate, and desired mesh size.

- Customize the Screen: Work with our team to design a screen that meets your unique specifications. Options include different mesh configurations, materials, and frame designs.

- Install the System: Follow the provided guidelines to integrate the screen into your existing filtration setup. Our technical support team is available for on-site assistance.

- Monitor and Maintain: While the screen operates automatically, regular inspections are recommended to ensure long-term reliability. Our maintenance team can provide scheduled check-ups.

For detailed instructions, visit our product page or contact our sales team for personalized guidance.

Ensuring Safety and Compliance: Environmental and Regulatory Standards

Safety and environmental responsibility are at the core of our product design. The Self-Cleaning Screen is manufactured using eco-friendly materials and processes that comply with international standards such as ISO 9001 and RoHS. Our screens are also tested for durability, corrosion resistance, and chemical compatibility to ensure they meet the rigorous demands of industrial applications.

By choosing our product, you not only enhance your operational efficiency but also contribute to a safer and more sustainable work environment. We provide comprehensive documentation, including safety data sheets and compliance certifications, to support your regulatory requirements.

Shipping and Packaging: Reliable Delivery for Large-Scale Orders

We understand that ToB clients often require bulk orders, and our packaging and logistics solutions are designed to meet these needs. The Self-Cleaning Screen is packaged in sturdy, weather-resistant containers to protect against damage during transit. Our global shipping network ensures timely delivery, with options for expedited shipping and customized packaging based on your requirements.

For more details on our shipping and packaging services, contact our customer support team. We also offer bulk order discounts and long-term partnership programs to support your business growth.

Comprehensive Support: From Technical Consultation to After-Sales Service

At Muto Wire Screen Co., Ltd., we pride ourselves on delivering exceptional customer service. Our team of experts is available to provide technical consultations, product training, and on-site support to ensure a seamless integration of the Self-Cleaning Screen into your operations.

After purchase, we offer a range of after-sales services, including:

- Warranty Coverage: Comprehensive warranty for all components, ensuring peace of mind.

- 24/7 Technical Support: Immediate assistance for any issues or inquiries.

- Customization Services: Flexible options to adapt the screen to your evolving needs.

Our goal is to build long-term relationships with our clients, providing ongoing support and innovation to help them achieve their business objectives.

Take the Next Step: Contact Muto Wire Screen Co., Ltd. Today

Ready to experience the benefits of the Self-Cleaning Screen? Muto Wire Screen Co., Ltd. is here to help you make the switch. Whether you’re looking to upgrade your filtration system, reduce operational costs, or improve efficiency, our team is committed to delivering solutions that exceed your expectations.

For more information, visit our product page or reach out to us directly at +86 138 3120 0000. Let us help you achieve a more efficient, sustainable, and profitable operation.

Frequently Asked Questions (FAQ)

1. How often does the Self-Cleaning Screen require maintenance?

The self-cleaning mechanism significantly reduces the need for manual maintenance. However, periodic inspections are recommended to ensure optimal performance. Our team can provide a maintenance schedule tailored to your specific application.

2. What industries can benefit from the Self-Cleaning Screen?

The Self-Cleaning Screen is suitable for a wide range of industries, including mining, construction, chemical processing, food and beverage, and wastewater treatment. Its versatility makes it an ideal solution for any application requiring efficient filtration.

3. Can the screen be customized for specific mesh sizes or materials?

Yes, we offer customized solutions to meet your unique requirements. Our engineers can design screens with specific mesh sizes, materials (e.g., stainless steel, carbon steel), and configurations.

4. What certifications does the product have?

The Self-Cleaning Screen complies with international standards such as ISO 9001 and RoHS. We also provide safety data sheets and compliance documentation upon request.

5. How long does it take to receive the product after placing an order?

Delivery times vary depending on the order size and shipping destination. Our logistics team works efficiently to ensure timely delivery, and we offer expedited shipping options for urgent needs.