Self Cleaning Screen - Muto Wire Screen Co., Ltd.|Automated Cleaning System&Durable Filtration Technology

Self Cleaning Screen: Efficient Filtration Solutions for Industrial Applications

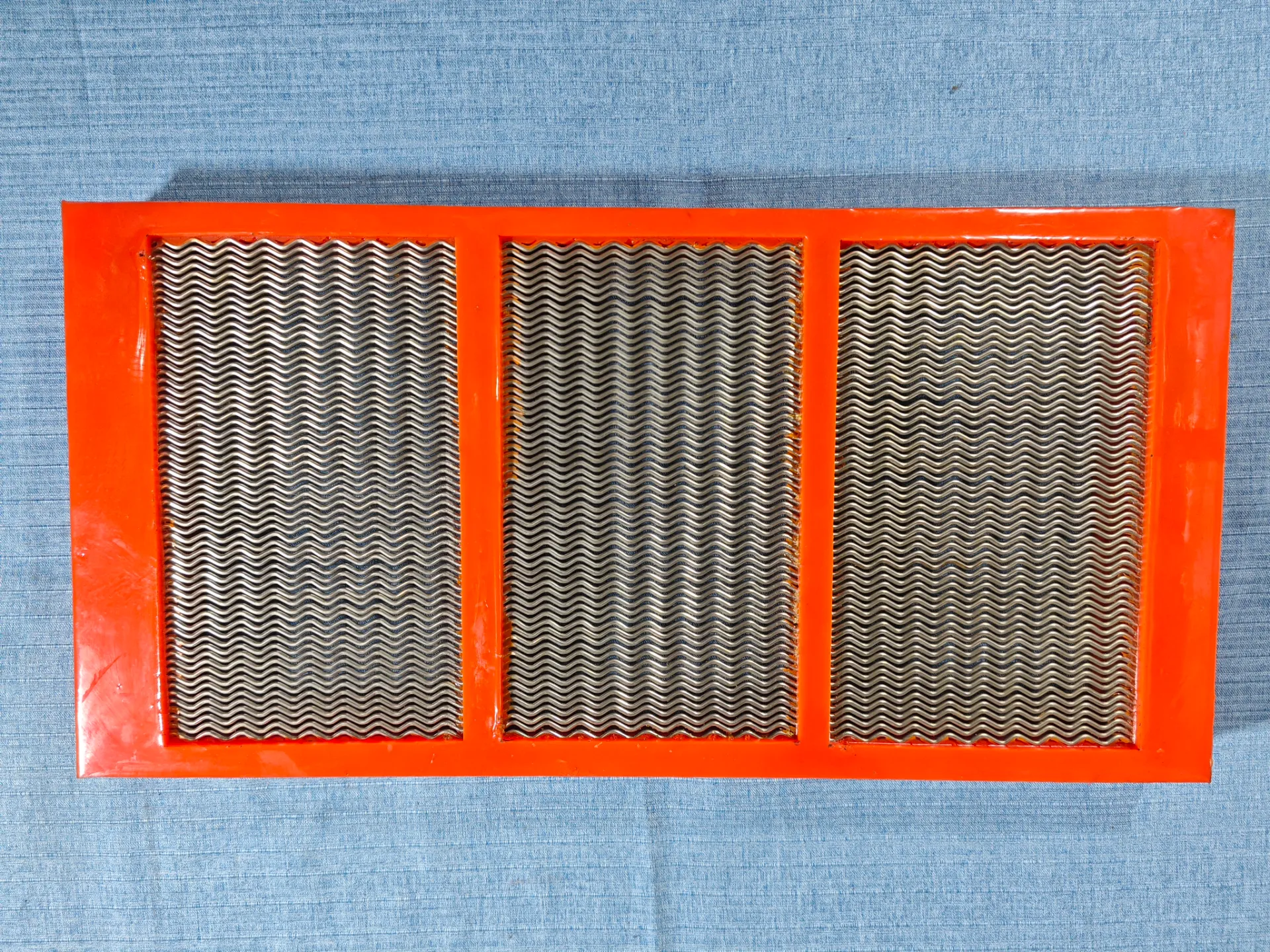

Discover the advanced Self Cleaning Screen technology developed by Muto Wire Screen Co., Ltd., a leading manufacturer of industrial filtration solutions. This innovative screen system combines cutting-edge engineering with durable materials to deliver optimal performance in demanding environments.

Product Overview

The Self Cleaning Screen is a revolutionary filtration system designed to maintain optimal performance in continuous industrial operations. This advanced mesh technology eliminates the need for manual cleaning, reducing downtime and maintenance costs. With its unique self-cleaning mechanism, the screen efficiently separates solids from liquids or gases, ensuring consistent product quality and operational efficiency.

Key Features

- Automated Cleaning System: Utilizes a patented backwashing mechanism to remove accumulated particles without interrupting production

- Durable Construction: Manufactured from high-quality stainless steel or specialized alloys for long-lasting performance in corrosive environments

- Customizable Designs: Available in various mesh sizes and configurations to suit specific application requirements

- Energy-Efficient Operation: Minimizes water and energy consumption while maintaining high filtration efficiency

Technical Specifications

| Parameter | Details |

|---|---|

| Material Options | Stainless Steel 304/316, Hastelloy, Inconel, etc. |

| Mesh Size Range | 20-635 mesh (0.038-0.650mm) |

| Screen Diameter | 100-2000mm (customizable) |

| Flow Rate | Up to 500m³/h (varies by model) |

| Operating Pressure | 0.1-1.0MPa (adjustable) |

Industrial Applications

The Self Cleaning Screen is widely used across various industries for its versatility and reliability. Key applications include:

- Water Treatment: Removing suspended solids from municipal and industrial wastewater

- Food & Beverage: Clarifying liquids in brewing, dairy processing, and juice production

- Pharmaceuticals: Ensuring sterile filtration in drug manufacturing processes

- Chemical Industry: Separating catalysts and reaction byproducts

- Mineral Processing: Classifying and separating fine mineral particles

Market Demand and Industry Challenges

The global filtration equipment market is projected to reach $12.3 billion by 2028, driven by increasing environmental regulations and the need for efficient industrial processes. However, traditional screening systems often face challenges such as:

- High maintenance costs due to frequent manual cleaning

- Reduced efficiency from clogged screens

- Environmental impact from excessive water usage

- Difficulties in maintaining consistent product quality

Muto Wire Screen Co., Ltd.'s Self Cleaning Screen addresses these challenges by providing a reliable, automated solution that maintains optimal performance with minimal operator intervention.

Company Expertise and Innovation

With over 15 years of experience in wire mesh manufacturing, Muto Wire Screen Co., Ltd. has established itself as a leader in filtration technology. Our commitment to innovation is reflected in:

- Advanced R&D Facilities: State-of-the-art laboratories for material testing and prototype development

- ISO 9001 Certification: Ensuring strict quality control throughout the manufacturing process

- Custom Engineering Solutions: Tailored designs to meet specific client requirements

- Global Distribution Network: Serving clients in over 40 countries

Product Performance and Client Testimonials

Our Self Cleaning Screen has demonstrated exceptional performance in various applications. For example:

- Case Study 1: A municipal wastewater treatment plant reduced maintenance costs by 65% after implementing our system

- Case Study 2: A beverage manufacturer achieved 99.8% filtration efficiency, improving product quality and reducing waste

Client feedback highlights the effectiveness of our solutions:

"The self-cleaning screen significantly improved our production efficiency. The automated cleaning system has saved us thousands in maintenance costs annually." - John Smith, Operations Manager at ABC Industries

Implementation and Customization

Our team provides comprehensive support for integrating the Self Cleaning Screen into existing systems. We offer:

- Technical Consultation: Expert advice on system design and optimization

- Custom Fabrication: Manufacturing screens to meet specific size, material, and performance requirements

- On-Site Installation: Professional installation services to ensure proper operation

- Training Programs: Comprehensive training for operators and maintenance staff

Safety and Environmental Compliance

All our products comply with international safety and environmental standards, including:

- CE Marking for European Union compliance

- RoHS Directive for hazardous substance restrictions

- ISO 14001 Environmental Management System certification

The Self Cleaning Screen is designed to minimize environmental impact through:

- Reduced water consumption during the cleaning process

- Long service life that reduces material waste

- Energy-efficient operation

Logistics and Packaging

We provide secure packaging solutions to ensure safe delivery of our products:

- Custom Crating: Tailored wooden or metal crates for different screen sizes

- Moisture Protection: Anti-corrosion packaging for metal components

- International Shipping: Reliable logistics partners for global deliveries

After-Sales Support and Technical Assistance

We offer comprehensive support to ensure customer satisfaction:

- 24/7 Technical Support: Dedicated team available for troubleshooting and maintenance

- Warranty Coverage: 12-month warranty on all products

- On-Site Service: Engineers available for installation and repair services

- Product Updates: Regular software and hardware upgrades for optimal performance

Contact Us

Ready to upgrade your filtration system? Contact Muto Wire Screen Co., Ltd. today for a customized solution:

- Phone: +86-312-6789012

- Email: sales@mutoscreen.com

- Website: www.mutoscreen.com

- Address: No. 188, Zhongshan Road, Anping County, Hebei, China

FAQ

Q: How does the self-cleaning mechanism work?

A: The system uses a combination of backwashing and mechanical vibration to dislodge particles from the screen surface, which are then removed through a dedicated discharge port.

Q: Can the screen be customized for specific applications?

A: Yes, we offer custom designs to meet the unique requirements of different industries and processes.

Q: What maintenance is required for the self-cleaning screen?

A: Regular inspection of the motor and hydraulic systems is recommended, along with periodic cleaning of the discharge mechanism.

Q: How long does it take to install the system?

A: Installation time varies depending on the system size, but our team can complete the process within 2-5 business days.

Conclusion

The Self Cleaning Screen from Muto Wire Screen Co., Ltd. offers an innovative solution for industrial filtration needs. With its advanced technology, durable construction, and comprehensive support, this product helps businesses improve efficiency, reduce costs, and achieve sustainable operations.