Self-Cleaning Screen - Muto Wire Screen Co., Ltd.|automated filtration&industrial efficiency

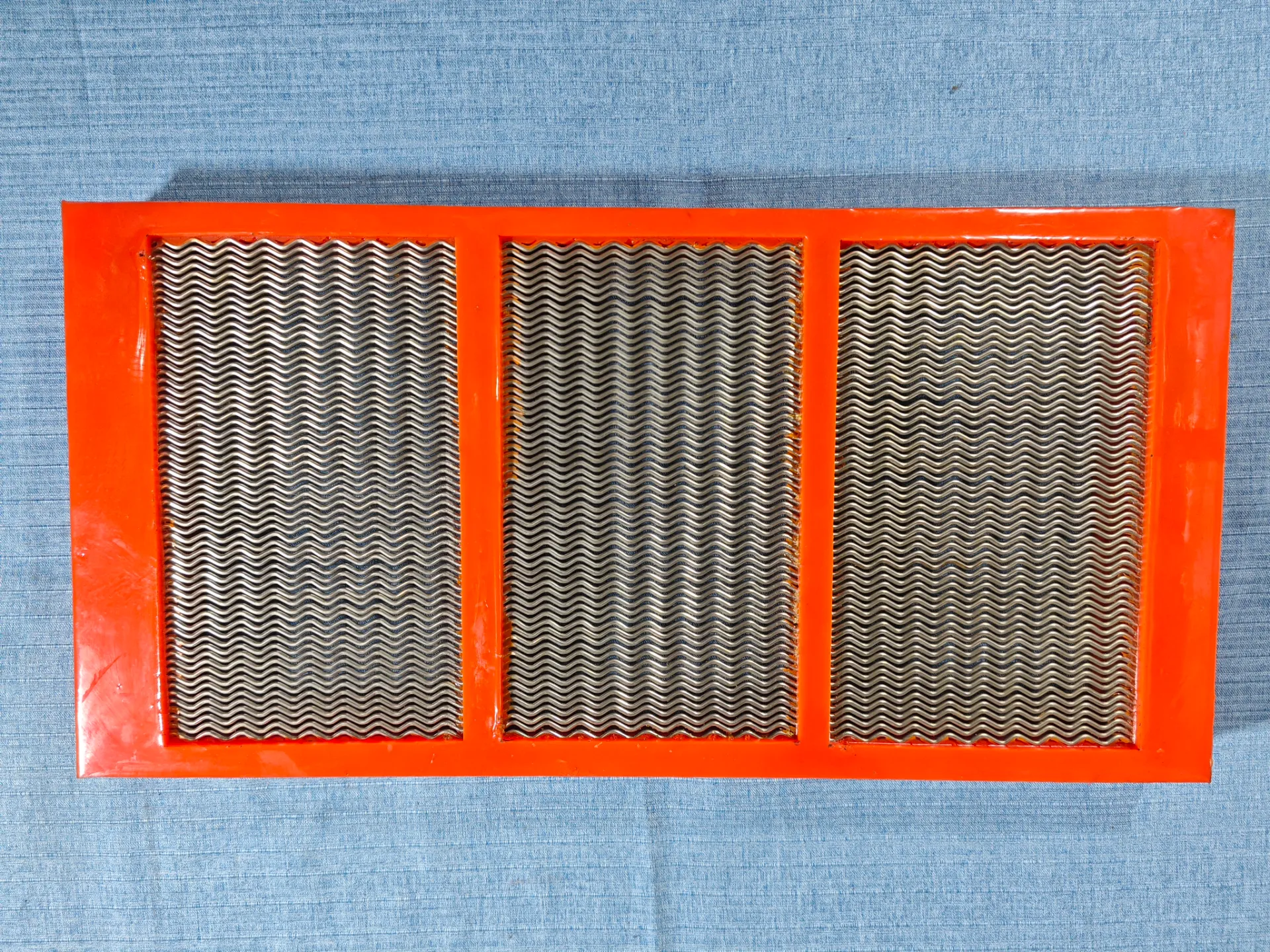

Self-Cleaning Screen: Revolutionizing Industrial Filtration Efficiency

At Muto Wire Screen Co., Ltd., we specialize in innovative filtration solutions that redefine industrial efficiency. Our Self-Cleaning Screen represents the pinnacle of engineering excellence, offering a smart, automated solution for demanding filtration applications. This advanced technology eliminates manual cleaning, reduces maintenance costs, and ensures consistent performance in critical processes.

Understanding Self-Cleaning Screens: A Technological Breakthrough

Self-cleaning screens are engineered to maintain optimal filtration performance through automated cleaning cycles. These systems use advanced mechanisms like reverse air pulses, water jets, or mechanical brushes to remove accumulated debris without interrupting the production process. The Self-Cleaning Screen from Muto Wire Screen Co., Ltd. incorporates precision-engineered self-cleaning screen mesh that combines high tensile strength with exceptional durability.

Key technical specifications include:

- Material: Stainless steel, carbon steel, or specialized alloys

- Mesh Sizes: 20-200 mesh (customizable)

- Operating Pressure: 0.1-1.5 MPa

- Cleaning Frequency: Adjustable 1-60 minutes

- Flow Capacity: 50-500 m³/h

Addressing Industry Challenges with Smart Filtration

Traditional filtration systems often face critical challenges that impact productivity and costs:

- Manual cleaning processes lead to downtime and labor expenses

- Clogged screens reduce throughput and energy efficiency

- Regular maintenance requires system shutdowns

- Contamination risks from inconsistent filtration

Our self-cleaning wire mesh technology directly addresses these issues through:

- Automated cleaning cycles that maintain optimal performance

- Continuous operation without production interruptions

- Reduced labor costs through minimal manual intervention

- Consistent filtration quality across all applications

Why Choose Muto Wire Screen Co., Ltd.?

With over 15 years of experience in the metal wire mesh industry, Muto Wire Screen Co., Ltd. has established itself as a leader in filtration technology. Our commitment to innovation is evident in our advanced manufacturing processes and rigorous quality control systems.

Key advantages include:

- Patented self-cleaning mechanisms for enhanced efficiency

- Customizable solutions for diverse industrial applications

- ISO 9001-certified production facilities

- Comprehensive technical support and after-sales service

Our aggregate screens are designed to meet the highest industry standards, ensuring reliable performance in even the most demanding environments.

Proven Performance in Real-World Applications

Customers across various industries have reported significant improvements with our self-cleaning screen systems:

Case Study 1: Mining Industry

One leading mining company implemented our self-cleaning screen mesh in their mineral processing line. The result: 40% reduction in maintenance costs and 25% increase in throughput.

Case Study 2: Food Processing

A food manufacturing plant reported a 60% decrease in product contamination incidents after upgrading to our self-cleaning wire mesh solution.

Implementation and Customization Options

Our self-cleaning screen systems are designed for seamless integration into existing processes. We offer:

- Modular designs for easy installation

- Customized screen configurations

- Integration with automated control systems

- Scalable solutions for different production volumes

For specific applications, we provide:

- Stainless steel self-cleaning screen mesh for corrosive environments

- High-temperature resistant options for industrial ovens

- Food-grade materials for pharmaceutical and food processing

Compliance and Safety Standards

All our self-cleaning wire mesh products meet international safety and quality standards. Features include:

- RoHS compliance for environmental safety

- CE certification for European markets

- Food-grade materials for pharmaceutical and food applications

- Anti-corrosion treatments for extended lifespan

Logistics and Packaging Solutions

We provide robust packaging solutions to ensure safe delivery of our self-cleaning screen systems:

- Custom wooden crates for heavy-duty components

- Moisture-proof packaging for sensitive materials

- Labeling for easy identification and handling

- Global shipping options with tracking capabilities

Comprehensive Customer Support

Our commitment to customer success includes:

- 24/7 technical support for installation and operation

- On-site training for maintenance personnel

- Warranty coverage for 12-24 months

- Regular maintenance and performance audits

For all inquiries, please contact us at:

- Phone: +86-312-6789012

- Email: sales@mutoscreen.com

- Website: www.mutoscreen.com

Conclusion

Invest in the future of industrial filtration with Muto Wire Screen Co., Ltd.'s Self-Cleaning Screen. Experience unparalleled efficiency, reduced operational costs, and reliable performance across all applications. Discover how our innovative solutions can transform your production processes today.

Frequently Asked Questions

Q1: How does the self-cleaning mechanism work?

A: Our system uses automated reverse air pulses to dislodge debris from the screen surface, ensuring continuous operation without manual intervention.

Q2: Can the cleaning frequency be adjusted?

A: Yes, the cleaning cycle can be customized between 1-60 minutes based on specific application requirements.

Q3: What materials are available for the screen mesh?

A: We offer stainless steel, carbon steel, and specialized alloys, with options for food-grade and corrosion-resistant treatments.

Q4: Is technical support available after installation?

A: Absolutely. Our team provides 24/7 technical assistance, on-site training, and regular maintenance services to ensure optimal performance.