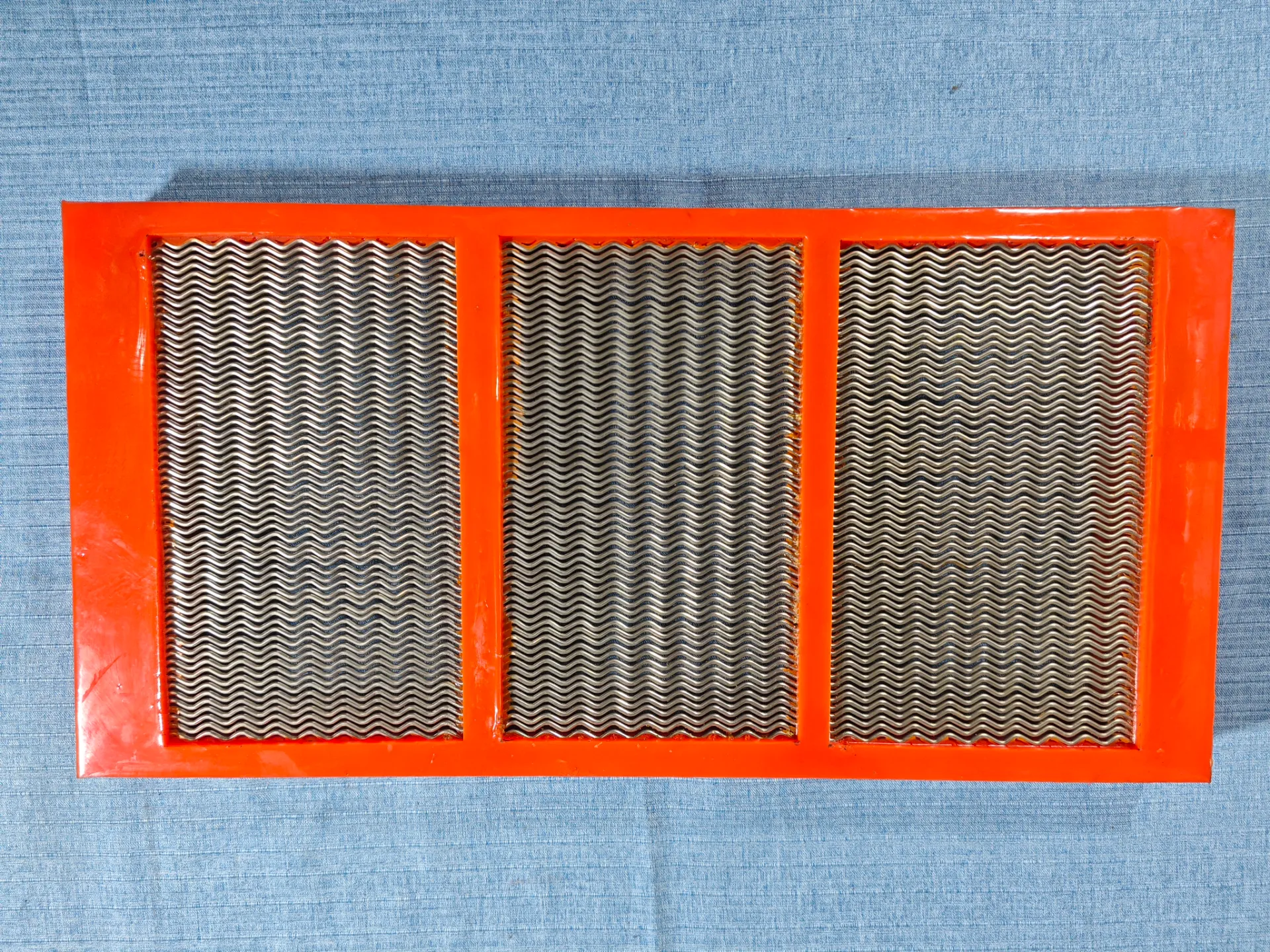

Self-Cleaning Screen: Enhancing Efficiency and Durability for Industrial Applications

At Muto Wire Screen Co., Ltd., we specialize in providing innovative self-cleaning screen solutions that revolutionize industrial filtration and separation processes. Our self-cleaning screen mesh and self-cleaning wire mesh are engineered to address the challenges of traditional screening systems, offering unmatched efficiency, durability, and cost-effectiveness. Whether you're in the aggregate solutions industry or require advanced aggregate screens, our products are designed to meet your unique needs. Discover how our self-cleaning mesh can transform your operations and elevate your productivity.

What is a Self-Cleaning Screen?

A self-cleaning screen is a specialized filtration system designed to automatically remove debris and contaminants without manual intervention. Unlike conventional screens that require frequent shutdowns for cleaning, our self-cleaning wire mesh utilizes advanced mechanisms such as vibration, air jets, or water flushing to maintain optimal performance. This technology ensures continuous operation, reduces downtime, and minimizes labor costs, making it an ideal solution for industries that demand high productivity and efficiency.

Key Features and Benefits of Our Self-Cleaning Screen

1. Enhanced Efficiency

Our self-cleaning screen mesh is designed to maintain a consistent flow rate by preventing clogging and blockages. This ensures that your production processes remain uninterrupted, even in demanding environments. The automated cleaning system reduces the need for manual cleaning, saving time and labor costs while improving overall operational efficiency.

2. Durable Construction

Constructed from high-quality materials, our self-cleaning wire mesh is built to withstand harsh conditions. The robust design ensures long-term performance, even in applications involving abrasive materials or high-temperature environments. This durability translates to lower maintenance requirements and extended service life, offering excellent value for money.

3. Versatile Applications

Our self-cleaning screen is suitable for a wide range of industries, including mining, food processing, chemical manufacturing, and water treatment. The aggregate screens we provide are tailored to meet the specific needs of each application, ensuring optimal performance and reliability. Whether you need to separate fine particles or filter liquids, our products deliver consistent results.

Industry Challenges and How Our Self-Cleaning Screen Addresses Them

Traditional screening systems often face several challenges that can impact productivity and operational costs. These include:

- Blockages and Clogging: Conventional screens are prone to clogging, leading to reduced efficiency and frequent shutdowns for cleaning.

- High Maintenance Costs: Manual cleaning and replacement of worn-out screens can be labor-intensive and expensive.

- Short Lifespan: Standard screens may degrade quickly under harsh conditions, requiring frequent replacements.

Our self-cleaning mesh is engineered to overcome these challenges. By incorporating advanced cleaning mechanisms, our products eliminate the need for manual intervention, reduce maintenance requirements, and extend the lifespan of the screens. This results in significant cost savings and improved operational efficiency for your business.

Why Choose Muto Wire Screen Co., Ltd.?

As a leading manufacturer of self-cleaning screen solutions, Muto Wire Screen Co., Ltd. has established itself as a trusted name in the industry. With years of experience and a commitment to innovation, we provide cutting-edge self-cleaning screen mesh and aggregate solutions that meet the highest standards of quality and performance.

1. Advanced Technology and R&D Capabilities

We invest heavily in research and development to stay at the forefront of filtration technology. Our team of experts continuously innovates to improve the efficiency, durability, and versatility of our products. This commitment to innovation ensures that our self-cleaning wire mesh remains competitive in the ever-evolving industrial landscape.

2. Customized Solutions for Your Industry

We understand that every industry has unique requirements. That's why we offer tailored aggregate screens and self-cleaning mesh solutions designed to meet your specific needs. Whether you need a solution for fine particle separation or large-scale filtration, our team works closely with you to develop the perfect system.

3. Global Reputation and Customer Satisfaction

Our products are trusted by businesses worldwide, and we take pride in our reputation for delivering reliable and high-performance solutions. Customer satisfaction is at the core of our operations, and we strive to exceed expectations with every project we undertake.

Technical Specifications of Our Self-Cleaning Screen

Our self-cleaning screen is available in a variety of configurations to suit different applications. Key specifications include:

- Material Options: Stainless steel, carbon steel, and other corrosion-resistant materials to ensure longevity in harsh environments.

- Screen Mesh Sizes: Available in a wide range of mesh sizes to accommodate various particle separation requirements.

- Cleaning Mechanisms: Vibration, air jets, or water flushing systems for automatic debris removal.

- Customizable Designs: Tailored to fit existing systems or integrated into new installations.

Applications of Self-Cleaning Screens in Various Industries

Our self-cleaning wire mesh is widely used across multiple industries, including:

- Mineral Processing: Efficient separation of ores and minerals, reducing downtime and maintenance costs.

- Food and Beverage: Ensuring hygienic and efficient filtration of liquids and semi-liquids, complying with strict food safety standards.

- Chemical Manufacturing: Filtering and separating chemical solutions with high precision and reliability.

- Water Treatment: Removing impurities from water sources, improving the quality of treated water.

Customer Success Stories

Our self-cleaning screen has been instrumental in helping businesses achieve operational excellence. Here are a few examples:

Case Study 1: Mining Industry

A leading mining company faced frequent clogging issues with their traditional screening systems, leading to significant production delays. By implementing our self-cleaning mesh, they reduced downtime by 40% and improved overall efficiency, resulting in substantial cost savings.

Case Study 2: Food Processing

A food processing facility needed a reliable solution for filtering liquid ingredients. Our self-cleaning wire mesh provided continuous operation with minimal maintenance, ensuring compliance with hygiene standards and reducing labor costs by 30%.

How to Implement Our Self-Cleaning Screen

Implementing our self-cleaning screen is a straightforward process, and our team provides comprehensive support to ensure a seamless integration into your operations:

- Consultation: Our experts will assess your specific requirements and recommend the most suitable solution.

- Design and Customization: We tailor the self-cleaning mesh to fit your existing systems or design a new solution.

- Installation: Our technicians ensure proper installation and provide on-site training for your team.

- Support and Maintenance: We offer ongoing technical support and maintenance services to keep your system running smoothly.

Ensuring Safety and Compliance

At Muto Wire Screen Co., Ltd., we prioritize safety and environmental compliance. Our self-cleaning screen is manufactured to meet international safety standards, ensuring a secure working environment for your employees. Additionally, the eco-friendly design of our products minimizes waste and reduces the environmental impact of your operations.

Packaging and Delivery

We understand the importance of reliable logistics for bulk orders. Our self-cleaning wire mesh is packaged in durable, protective containers to ensure safe transportation. We offer flexible delivery options to meet your schedule, with dedicated support from our logistics team to ensure timely and efficient delivery.

Comprehensive Customer Support

We are committed to providing exceptional customer support to ensure your satisfaction. Our team is available to address any inquiries or technical issues you may encounter. Whether you need assistance with installation, maintenance, or product customization, we are here to help. Contact us today to learn more about how our self-cleaning screen can benefit your business.

FAQ: Frequently Asked Questions

Q1: How long does the self-cleaning screen last?

A: With proper maintenance, our self-cleaning mesh can last for several years, depending on the operating conditions and usage frequency.

Q2: What is the maintenance requirement for the self-cleaning wire mesh?

A: The automated cleaning system significantly reduces maintenance needs. However, periodic inspections and minor adjustments may be required to ensure optimal performance.

Q3: Can the self-cleaning screen be customized for specific applications?

A: Yes, we offer tailored solutions to meet the unique requirements of your industry. Our team will work closely with you to design the perfect system.

Conclusion

Invest in a self-cleaning screen from Muto Wire Screen Co., Ltd. and experience the difference in efficiency, durability, and cost savings. Our self-cleaning mesh and aggregate solutions are designed to meet the highest standards of performance, ensuring your operations run smoothly and profitably. Contact us today to learn more about how we can help you achieve your goals.

Explore Our Products

For more information about our self-cleaning screen and other industrial solutions, visit our company website. Discover how our self-cleaning wire mesh can transform your production processes and deliver exceptional value to your business.