Self-Cleaning Screen-Muto Wire Screen Co., Ltd.|Industrial Filtration&Automatic Cleaning

Self-Cleaning Screen: Revolutionizing Industrial Filtration and Separation

Discover how Self-Cleaning Screen is transforming industrial filtration and separation processes. Developed by Muto Wire Screen Co., Ltd., a leader in metal wire mesh solutions, our self-cleaning screens offer advanced technology to enhance efficiency, reduce maintenance, and improve productivity across various industries. Explore the innovative features and benefits of this cutting-edge filtration solution.

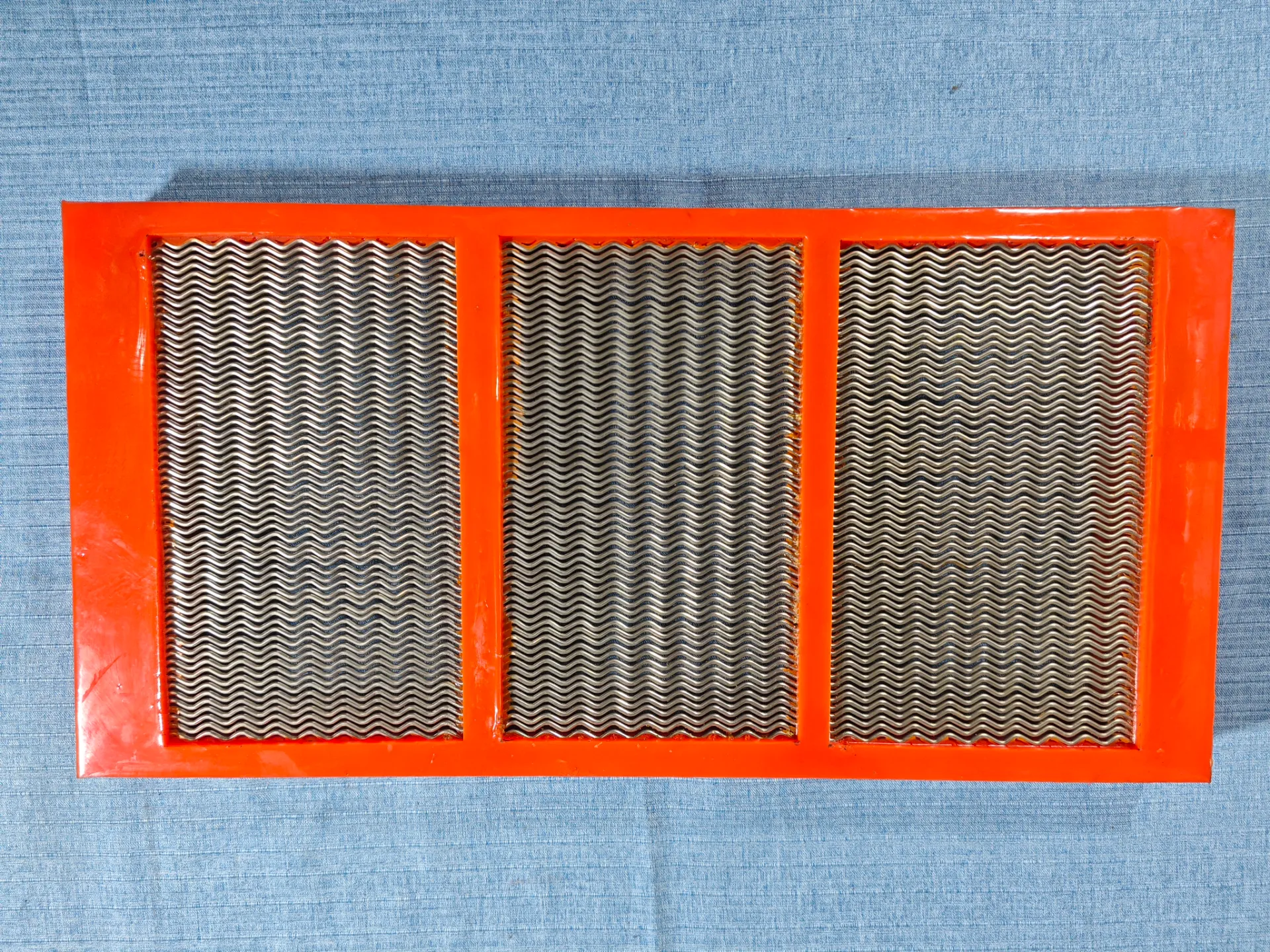

What is a Self-Cleaning Screen?

A Self-Cleaning Screen is an advanced filtration system designed to automatically remove debris and contaminants from the screen surface without manual intervention. Unlike traditional screens that require frequent shutdowns for cleaning, our self-cleaning technology ensures continuous operation, significantly improving efficiency and reducing downtime. This innovation is particularly valuable in industries where uninterrupted processing is critical, such as agriculture, mining, and wastewater treatment.

Key Features and Technical Specifications

- Self-Cleaning Mechanism: Utilizes a rotating brush or air jet system to remove blockages automatically.

- Durable Materials: Constructed from high-quality stainless steel or other corrosion-resistant metals for long-lasting performance.

- Customizable Mesh Sizes: Available in various mesh sizes (e.g., self cleaning wire mesh) to suit different filtration needs.

- High Flow Capacity: Optimized design allows for maximum throughput without compromising filtration efficiency.

- Low Maintenance: Minimizes the need for manual cleaning, reducing labor costs and maintenance frequency.

Applications Across Industries

Our Self-Cleaning Screen is widely used in diverse sectors, including:

- Agriculture: For sorting and cleaning seeds, fertilizers, and soil particles.

- Mineral Processing: To separate aggregates and minerals efficiently.

- Wastewater Treatment: Removing impurities and solids from water streams.

- Food and Beverage: Ensuring hygiene and quality by filtering liquids and ingredients.

- Chemical Industry: Filtering chemicals and suspensions with precision.

Why Choose Muto Wire Screen Co., Ltd.?

As a leading manufacturer of metal wire mesh solutions, Muto Wire Screen Co., Ltd. has established itself as a trusted name in the industry. With over 15 years of experience, we combine advanced technology with rigorous quality control to deliver products that meet the highest standards. Our commitment to innovation ensures that our self-cleaning screens are not only durable but also highly efficient, providing long-term value to our clients.

Benefits for Your Business

Investing in Self-Cleaning Screens offers numerous advantages for your operations:

- Increased Productivity: Continuous operation reduces downtime and boosts output.

- Cost Savings: Lower maintenance and labor costs compared to traditional systems.

- Improved Efficiency: Enhanced filtration accuracy and faster processing times.

- Environmental Compliance: Reduces waste and ensures sustainable practices.

Customer Testimonials

"Since implementing Muto's Self-Cleaning Screen, our production efficiency has increased by 30%. The reduction in maintenance time has allowed us to focus on other critical areas of our business." – John Doe, Production Manager at ABC Industries

How to Use and Maintain the Self-Cleaning Screen

Proper installation and regular maintenance are essential to maximize the performance of your Self-Cleaning Screen. Follow these guidelines:

- Installation: Ensure the screen is securely mounted in the designated location with proper alignment.

- Operation: Monitor the system for optimal performance and adjust settings as needed.

- Maintenance: Regularly inspect the brush or air jet system for wear and replace parts as required.

Custom Solutions for Your Needs

At Muto Wire Screen Co., Ltd., we understand that every business has unique requirements. Our team of experts works closely with clients to design custom self-cleaning screens tailored to specific applications. Whether you need a specialized self-cleaning mesh or an integrated filtration system, we provide solutions that meet your exact specifications.

Environmental and Safety Compliance

Our Self-Cleaning Screens are designed with environmental and safety standards in mind. All materials are non-toxic and meet international regulatory requirements. The automated cleaning process minimizes the risk of chemical exposure, ensuring a safer working environment for your team.

Ordering and Delivery

For bulk orders, we offer flexible packaging options to ensure the safe transport of our Self-Cleaning Screens. Our logistics team coordinates timely delivery to meet your production schedules. Contact us today to discuss your requirements and receive a personalized quote.

Support and Technical Assistance

We are committed to providing exceptional customer support. Our dedicated team offers 24/7 technical assistance, including installation guidance, troubleshooting, and maintenance advice. For more information, visit our company website or contact us directly.

Get in Touch

Ready to upgrade your filtration system? Contact Muto Wire Screen Co., Ltd. today to learn more about our Self-Cleaning Screens. Our sales representatives are available at +(86) 123-456-7890 or via online inquiry to assist you with your order.

Frequently Asked Questions (FAQ)

What industries benefit most from self-cleaning screens?

Self-cleaning screens are ideal for agriculture, mining, wastewater treatment, food processing, and chemical industries, where continuous filtration is essential.

How does the self-cleaning mechanism work?

The system uses a rotating brush or air jet to remove debris automatically, ensuring the screen remains unobstructed without manual intervention.

Can the mesh size be customized?

Yes, we offer a range of mesh sizes to suit different applications. Contact us for personalized recommendations.

What is the maintenance schedule for the screen?

Regular inspections are recommended, with part replacements as needed. Our team can provide a detailed maintenance plan based on your usage.

Is the product environmentally friendly?

Yes, our screens are made from non-toxic materials and are designed to reduce waste, supporting sustainable operations.

Conclusion: Self-Cleaning Screens from Muto Wire Screen Co., Ltd. are a game-changer for industrial filtration. With their advanced technology, durability, and custom solutions, they offer a reliable way to enhance efficiency and reduce costs. Discover the difference today!