Self-Cleaning Screen-Muto Wire Screen Co., Ltd.-Self-Cleaning Screen Mesh&Self-Cleaning Wire Mesh

Self-Cleaning Screen: Enhancing Efficiency with Muto Wire Screen Co., Ltd.

Discover how Muto Wire Screen Co., Ltd. revolutionizes industrial filtration with its advanced Self-Cleaning Screen solutions. Designed for precision and durability, our self-cleaning screen mesh and self-cleaning wire mesh deliver unmatched performance across diverse applications. Explore how our aggregate solutions and aggregate screens optimize your operations.

Product Overview: The Power of Self-Cleaning Technology

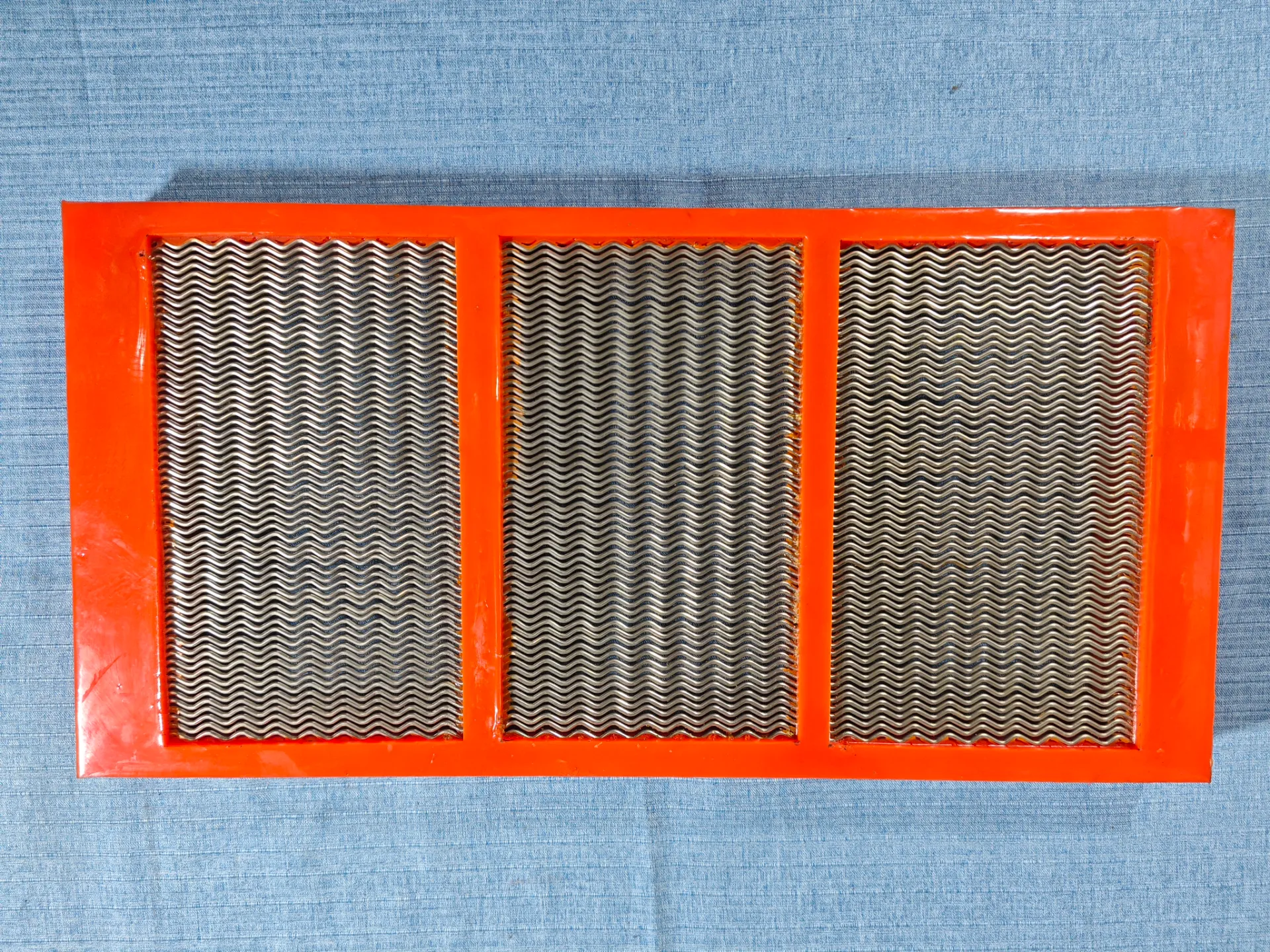

The Self-Cleaning Screen is a revolutionary filtration system engineered to maintain optimal performance without manual intervention. Utilizing self-cleaning screen mesh and self-cleaning wire mesh, our product automatically removes debris and contaminants, ensuring continuous efficiency. This innovation is ideal for industries requiring high-volume processing, such as mining, agriculture, and water treatment.

Technical Specifications: Precision Engineering for Industrial Demands

Our Self-Cleaning Screen is crafted with high-quality materials, including stainless steel and carbon steel, to withstand harsh environments. The self-cleaning wire mesh features a mesh size range of 100 to 800, allowing for customizable filtration. The advanced self-cleaning screen mesh incorporates a rotating or vibrating mechanism to dislodge particles, ensuring minimal downtime and maintenance.

Applications: Versatile Solutions for Diverse Industries

From aggregate screens in mining to self-cleaning screen mesh in agricultural processing, our product adapts to various needs. In water treatment, the self-cleaning wire mesh efficiently filters impurities, while in food processing, it maintains hygiene standards. The aggregate solutions provided by Muto Wire Screen Co., Ltd. ensure seamless integration into existing systems.

Company Background: A Leader in Wire Mesh Innovation

Established with over 15 years of expertise, Muto Wire Screen Co., Ltd. specializes in self-cleaning screen mesh and self-cleaning wire mesh solutions. Our commitment to quality is reflected in our ISO-certified production processes and partnerships with global industries. As a trusted provider of aggregate screens, we deliver reliable performance and customer satisfaction.

Key Advantages: Why Choose Muto Wire Screen Co., Ltd.?

- Enhanced Efficiency: The self-cleaning screen reduces manual labor and downtime, boosting productivity.

- Cost Savings: With minimal maintenance requirements, our self-cleaning wire mesh lowers operational costs.

- Customization: Tailored aggregate solutions to meet specific industry needs.

- Durability: High-grade materials ensure longevity in challenging environments.

Customer Testimonials: Real-World Success Stories

"Muto's self-cleaning screen mesh transformed our mining operations. The efficiency gains are remarkable!" – John D., Mining Industry Client

"We rely on their self-cleaning wire mesh for water treatment. The reliability and performance are unmatched." – Sarah L., Environmental Services Manager

Implementation and Support: Seamless Integration and Expert Guidance

Our team provides comprehensive aggregate screens installation support, ensuring optimal performance. With 24/7 technical assistance and customizable self-cleaning screen configurations, we guarantee a hassle-free experience. Explore our product page for detailed specifications and application guides.

Safety and Compliance: Built for Reliability

All self-cleaning wire mesh products meet international safety and environmental standards. The self-cleaning screen mesh is designed to minimize waste and reduce chemical usage, aligning with sustainable practices. Our aggregate solutions prioritize both operator safety and regulatory compliance.

Packaging and Delivery: Efficient Logistics for Global Clients

Our self-cleaning screen is packaged with protective layers to ensure safe transit. We offer flexible shipping options, including international delivery, to accommodate your requirements. Visit our company site to learn more about our logistics services.

Conclusion: Elevate Your Operations with Muto Wire Screen Co., Ltd.

Transform your industrial processes with Muto Wire Screen Co., Ltd.'s Self-Cleaning Screen. Experience the benefits of self-cleaning wire mesh and self-cleaning screen mesh today. Contact us for a consultation and discover how our aggregate solutions can optimize your workflow.

Frequently Asked Questions (FAQ)

Q: How does the self-cleaning mechanism work?

A: The self-cleaning screen mesh uses a rotating or vibrating system to automatically remove debris, ensuring continuous operation without manual intervention.

Q: Can the mesh size be customized?

A: Yes, our self-cleaning wire mesh is available in a range of mesh sizes (100 to 800) to suit your specific filtration needs.

Q: What industries benefit most from this product?

A: The aggregate screens and self-cleaning screen are ideal for mining, agriculture, water treatment, and food processing industries.

Q: Is technical support available?

A: Absolutely. Our team provides 24/7 technical assistance and on-site support to ensure seamless integration of our aggregate solutions.

Q: What certifications do your products hold?

A: All products are ISO-certified and comply with international safety and environmental standards.

Explore our product page for more details or contact us at info@mutoscreen.com for personalized assistance.