Sieve Bend Screen: The Perfect Choice for Precision Separation in Industrial Filtration

In the world of industrial filtration and solid-liquid separation, the sieve bend screen has become an indispensable tool for companies aiming for higher efficiency and better product quality.

Differences Between Sieve Bend Screen and Linear Screen

When choosing between a sieve bend screen and a linear screen, understanding their core differences is crucial. The sieve bend screen operates on the principle of centrifugal action. As material flows over the curved screen surface, finer particles quickly separate from liquids, while larger particles are efficiently carried away. This action allows for a much higher dewatering efficiency in a smaller space compared to linear screens.

Linear screens, on the other hand, rely on horizontal vibration to move the material across a flat surface, using gravity and motion to achieve separation. Although effective in certain applications, linear screens generally have lower throughput and take up more space compared to a Static Sieve Bend Screen.

The compactness, low maintenance, and high throughput of a sieve bend make it the ideal solution for industries like mining, food processing, water treatment, and paper production, where efficiency and space-saving are critical.

Design Angle and Functional Relationship of Sieve Bend Screen

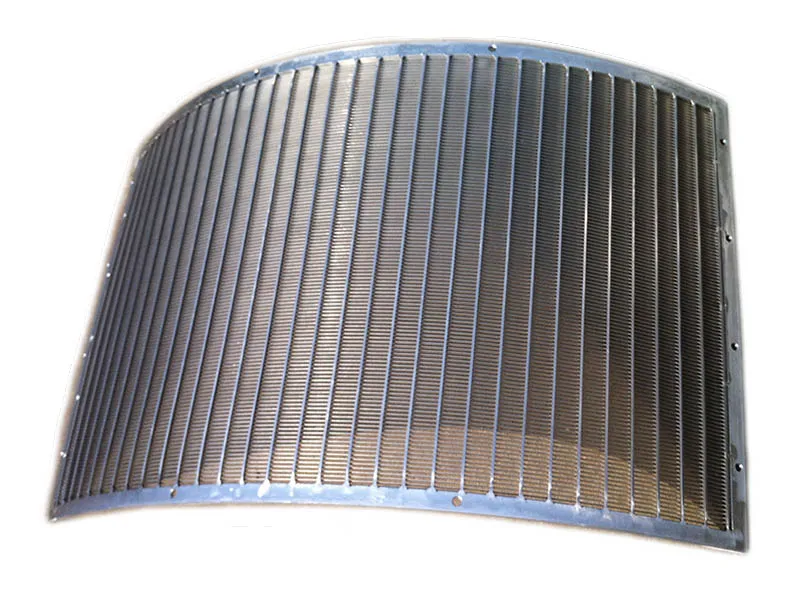

One of the most critical aspects of the sieve bend screen design is its unique curvature and the precise angle at which the screen is positioned. Typically, the screen is designed with a curve angle between 45° and 60°, depending on the specific application.

This curved design dramatically increases the screening area within a compact footprint, enhancing both the flow rate and the separation efficiency. The Static Sieve Bend Screen ensures that as material moves along the curved surface, it experiences increasing gravitational force, which accelerates particle separation without the need for external mechanical energy.

The functional relationship between the design angle and screening efficiency cannot be overstated. A steeper angle increases the dewatering efficiency, while a flatter angle provides finer particle separation. The ability to tailor the sieve bend design angle to specific operational needs offers unmatched versatility, allowing it to outperform traditional flat screens in both performance and economy.

Common Specifications of Sieve Bend Screen

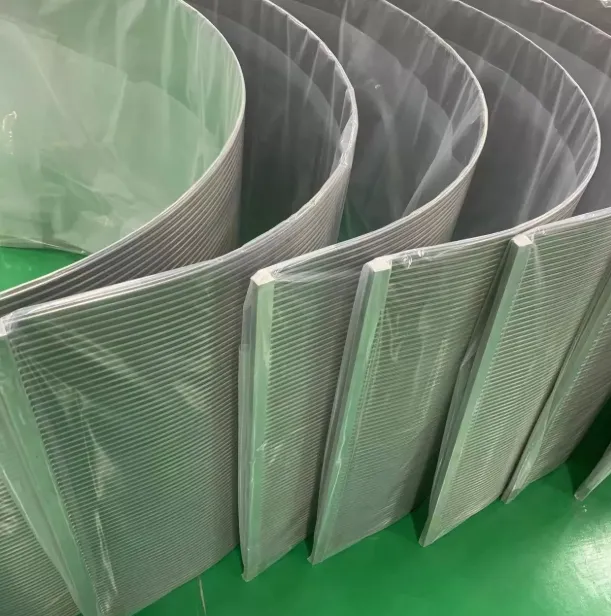

Choosing the right sieve bend screen involves understanding the common specifications offered by leading manufacturers. Generally, the screen width can range from 300mm to over 1500mm, while the arc length typically varies between 900mm and 1200mm, depending on application requirements.

The slot openings—the spaces between the screen wires—are another important specification. They usually range from 0.05mm to 2mm, allowing the Static Sieve Bend Screen to efficiently separate particles of different sizes. Screens can be manufactured using materials like stainless steel, offering excellent resistance to corrosion and abrasion, critical for operations in harsh chemical or mining environments.

Additionally, sieve bend options can include replaceable screen panels, modular construction, and customizable mounting frames to suit various industrial setups. The ability to customize these specifications ensures that the sieve bend screen fits perfectly into any processing line, providing maximum performance and longevity.

The Unmatched Advantages of Choosing Sieve Bend Screen

The sieve bend screen stands out for its simplicity, durability, and efficiency. Unlike mechanical screens that require regular maintenance and energy input, the Static Sieve Bend Screen works without any moving parts, greatly reducing operational costs and downtime.

Another significant advantage is the very high capacity to footprint ratio. Industries that struggle with limited installation space find the sieve bend particularly appealing because it can handle large volumes of material without requiring expansive equipment.

Moreover, the robust construction of the sieve bend screen, often using wedge wire profiles, ensures a long service life even under continuous heavy-duty operation. Whether separating fine solids from slurry in wastewater treatment or dewatering minerals in mining, the Static Sieve Bend Screen delivers consistent, reliable performance with minimal maintenance.

Customization is another strong point. Whether you need tighter slot openings, corrosion-resistant alloys, or specific design angles, top suppliers can tailor the sieve bend to meet your exact process requirements, ensuring the best fit and the best return on investment.

Sieve Bend Screen FAQs

What is the main difference between a sieve bend screen and a linear screen?

The sieve bend screen uses centrifugal force and gravity to separate particles on a curved surface, offering higher efficiency in a smaller space, while a linear screen relies on horizontal vibration and usually requires more space.

What is the ideal design angle for a Static Sieve Bend Screen?

The Static Sieve Bend Screen is typically designed at an angle between 45° and 60°, depending on the specific separation and dewatering needs of the application.

What are the typical slot openings available for sieve bend screens?

Sieve bend slot openings usually range from 0.05mm to 2mm, allowing for efficient separation of different particle sizes in a wide variety of industrial processes.

What materials are used to manufacture sieve bend screens?

Most sieve bend screens are made from stainless steel or specialized corrosion-resistant alloys, ensuring excellent durability and long-term performance in harsh operating environments.

Why should industries choose a sieve bend screen over other types of screening equipment?

The sieve bend screen offers higher throughput, lower maintenance, compact design, and greater separation efficiency compared to traditional screening equipment, making it the ideal choice for industries needing reliable solid-liquid separation solutions.