Vibrating Screen Backing Plate-Muto Wire Screen Co., Ltd.|Durability, Efficiency, Customization

Vibrating Screen Backing Plate: Enhancing Efficiency in Industrial Sieving

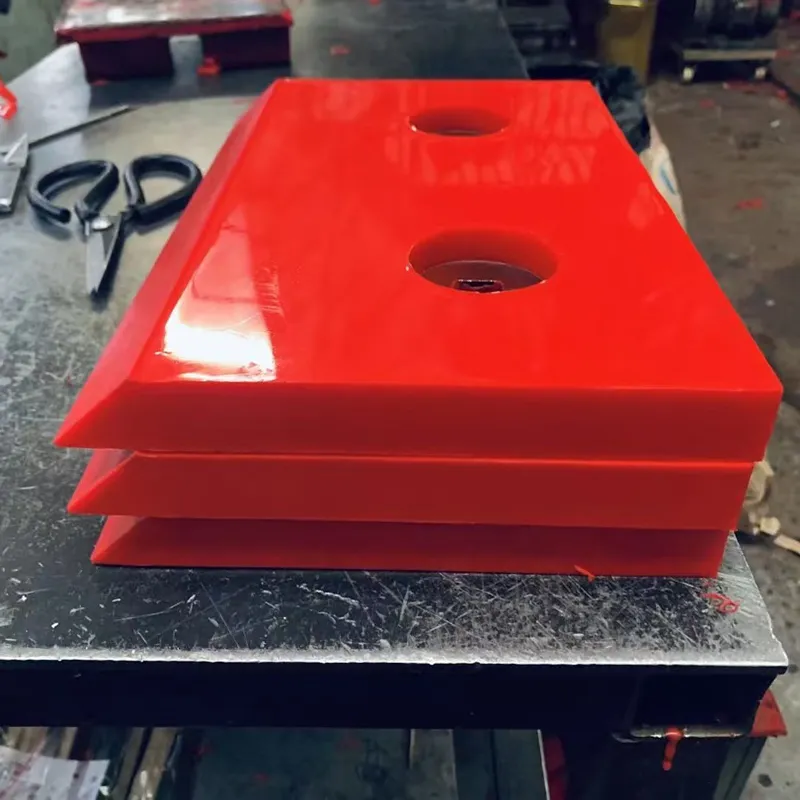

For industries reliant on precise material separation, the vibrating screen backing plate is a critical component that ensures optimal performance. Developed by Muto Wire Screen Co., Ltd., this advanced solution combines durability with precision engineering to meet the demands of modern industrial sieving applications.

Understanding the Function and Benefits

The vibrating screen backing plate serves as the foundational support structure for polyurethane screens, providing stability and ensuring even distribution of material across the screening surface. Its primary function is to enhance the efficiency of vibration systems by maintaining consistent contact between the screen mesh and the material being processed. This results in improved screening accuracy, reduced wear and tear, and extended service life for industrial sieving equipment.

Key advantages of the polyurethane screen backing plate include:

- High Durability: Crafted from high-quality polyurethane, these backing plates resist abrasion, impact, and chemical exposure, making them ideal for harsh industrial environments.

- Enhanced Efficiency: The design minimizes energy consumption while maximizing screening capacity, ensuring consistent performance even under heavy workloads.

- Easy Maintenance: The corrosion-resistant properties of polyurethane reduce the need for frequent replacements, lowering long-term operational costs.

- Customizable Solutions: Muto Wire Screen Co., Ltd. offers tailored backing plates to fit a wide range of vibrating screen models and application requirements.

Technical Specifications and Applications

The vibrating screen backing plate is engineered to meet rigorous industrial standards. Key technical specifications include:

- Material: High-density polyurethane (PU) with exceptional wear resistance.

- Thickness: 15-30mm, optimized for different screening applications.

- Load Capacity: Up to 500kg/m², ensuring stability during high-intensity operations.

- Surface Texture: Micro-roughened design for improved material adhesion and screening accuracy.

These backing plates are widely used in industries such as:

- Mineral Processing: For separating ores and aggregates with high precision.

- Agri-Food: In grain and seed sorting to maintain product quality.

- Chemical Manufacturing: For isolating powders and granules with minimal contamination risk.

- Recycling: To efficiently sort recyclable materials like plastics and metals.

Market Demand and Industry Challenges

The global demand for polyurethane screens and vibrating screens has surged due to their superior performance compared to traditional metal alternatives. However, industries face challenges such as:

- Wear and Tear: Metal screens often degrade quickly under continuous use, leading to frequent replacements.

- Energy Inefficiency: Outdated screening systems consume excessive power, increasing operational costs.

- Material Contamination: Poorly designed screens may introduce impurities into the final product.

Muto Wire Screen Co., Ltd. addresses these issues through its PU screen panel technology, which offers a combination of resilience, efficiency, and hygiene. By replacing conventional metal components with polyurethane backing plates, industries can achieve significant cost savings and operational improvements.

Company Expertise and Innovation

As a leading manufacturer in Anping County Muto Metal Wire Mesh Products Co., Ltd., Muto Wire Screen Co., Ltd. has established itself as a trusted provider of industrial screening solutions. With over two decades of experience, the company has developed a reputation for:

- Advanced R&D Capabilities: Dedicated to innovating materials and designs that meet evolving industry needs.

- Quality Assurance: Rigorous testing processes to ensure compliance with international standards like ISO 9001.

- Global Reach: Serving clients across 40+ countries with reliable, high-performance screening equipment.

Proven Results and Customer Testimonials

Companies that have adopted Muto's vibrating screen backing plate report measurable improvements in productivity. For instance:

"Since switching to Muto's polyurethane backing plates, our screening efficiency has increased by 30%, and maintenance costs have dropped by 40%." - John D., Mining Equipment Manager, Australia

Another user shared:

"The durability of these backing plates has exceeded our expectations. They've significantly reduced downtime in our food processing plant." - Emily R., Production Head, Germany

Implementation and Customization

Muto Wire Screen Co., Ltd. offers comprehensive support for integrating PU screen panels into existing systems. This includes:

- Technical Consultation: Expert guidance to select the optimal backing plate design for specific applications.

- Custom Manufacturing: Tailored solutions to match unique equipment dimensions and operational requirements.

- Installation Services: Professional assistance to ensure seamless integration with vibrating screens.

Safety and Environmental Compliance

Muto's vibrating screen backing plates are designed with safety and sustainability in mind. The polyurethane material is non-toxic, recyclable, and free from hazardous substances, ensuring compliance with global environmental regulations. Additionally, the plates' low friction properties reduce energy consumption, contributing to a smaller carbon footprint.

Packaging and Logistics

To accommodate bulk orders, Muto provides durable packaging that protects the backing plates during transportation. The company partners with trusted logistics providers to ensure timely delivery worldwide. For detailed shipping information, visit the Muto Wire Screen Co., Ltd. website.

Support and After-Sales Services

Muto Wire Screen Co., Ltd. stands behind its products with a robust after-sales support system, including:

- 24/7 Technical Support: Immediate assistance for troubleshooting and maintenance.

- Warranty Coverage: 12-month warranty on all backing plates to guarantee quality and performance.

- On-Site Training: Customized training sessions to optimize the use of screening equipment.

Get in Touch

For more information about the vibrating screen backing plate or to request a custom quote, contact Muto Wire Screen Co., Ltd. today:

- Phone: +86-312-6758888

- Email: sales@mutoscreen.com

- Website: https://www.mutoscreen.com

Conclusion

Invest in high-performance vibrating screen backing plates from Muto Wire Screen Co., Ltd. to enhance efficiency, reduce costs, and ensure sustainable operations. Experience the difference of premium polyurethane technology today.

Frequently Asked Questions (FAQ)

Q: What materials are used in Muto's vibrating screen backing plates?

A: The backing plates are made from high-density polyurethane (PU), known for its exceptional durability and resistance to wear and tear.

Q: Can these backing plates be customized for specific equipment?

A: Yes, Muto offers customized solutions to fit a wide range of vibrating screen models and application requirements.

Q: Are the backing plates environmentally friendly?

A: Absolutely. The polyurethane material is non-toxic, recyclable, and compliant with international environmental standards.

Q: What support is available after purchasing the product?

A: Muto provides 24/7 technical support, a 12-month warranty, and on-site training to ensure optimal performance and customer satisfaction.