Vibrating Screen Backing Plate: Enhancing Efficiency and Durability in Industrial Screening

Industrial screening processes rely heavily on the performance of critical components like vibrating screen backing plates. As a leading manufacturer in the metal wire mesh industry, Muto Wire Screen Co., Ltd. specializes in producing high-quality vibrating screen backing plates that address common challenges in screening operations. This article explores the technical specifications, applications, and benefits of our backing plates, while highlighting our commitment to innovation and customer satisfaction.

Product Overview and Core Functionality

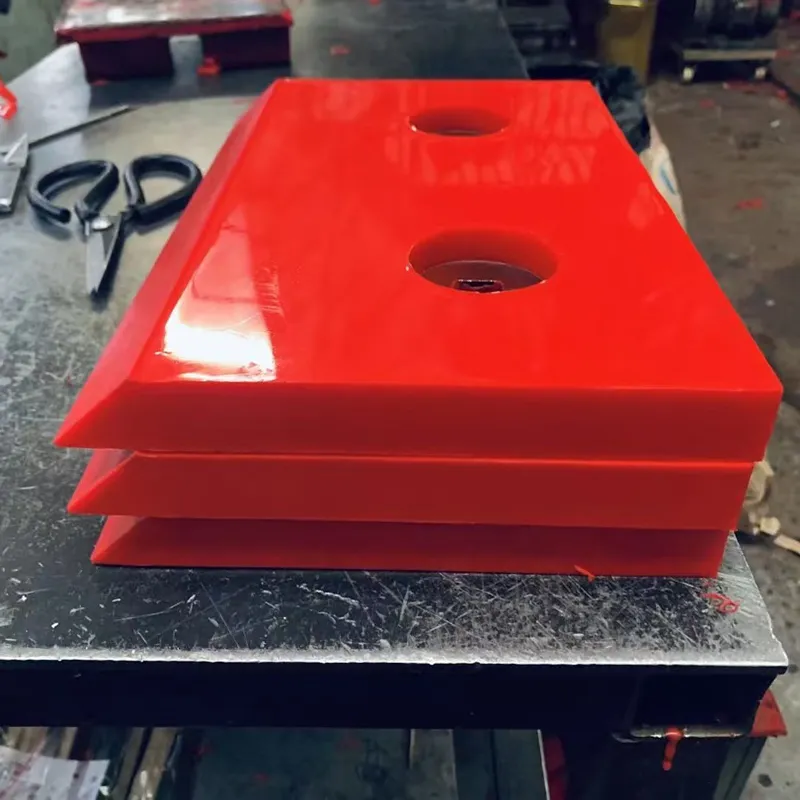

The vibrating screen backing plate serves as a critical structural component in screening equipment, providing support for the screen mesh while minimizing material wear. Our backing plates are engineered to withstand high-impact forces and abrasive materials, ensuring long-term reliability in demanding industrial environments.

Constructed from premium-grade materials, these backing plates feature a robust design that enhances the overall efficiency of screening operations. Their unique geometry allows for optimal material flow, reducing clogging and improving separation accuracy. Whether handling raw minerals, agricultural products, or construction materials, our backing plates deliver consistent performance across diverse applications.

Key Technical Specifications

Our vibrating screen backing plates are manufactured to meet rigorous industry standards, with specifications including:

- Material: High-strength steel or polyurethane (customizable based on application requirements)

- Surface Treatment: Corrosion-resistant coating for extended service life

- Dimensions: Customizable to fit various screen frame configurations

- Load Capacity: Designed to handle heavy-duty operations without deformation

- Surface Texture: Optimized for improved material adhesion and reduced wear

These technical features ensure that our backing plates maintain structural integrity even under extreme operating conditions, making them ideal for continuous industrial use.

Applications Across Industries

The versatility of vibrating screen backing plates makes them essential in multiple sectors, including:

- Mineral Processing: Efficient separation of ores, coal, and sand in mining operations.

- Agri-Food Industry: Sorting and grading of grains, seeds, and processed food products.

- Construction Materials: Screening of aggregates, cement, and asphalt components.

- Recycling Facilities: Sorting of plastics, metals, and other recyclable materials.

By integrating our backing plates into screening systems, businesses can achieve higher throughput rates while maintaining product quality. The plates' durable design also reduces downtime caused by frequent replacements, contributing to overall operational efficiency.

Addressing Industry Challenges

Traditional screening systems often face challenges such as rapid wear, material blockages, and inconsistent performance. Our vibrating screen backing plates directly address these issues through innovative design and material selection:

- Reduced Maintenance: The plates' wear-resistant properties significantly lower the frequency of replacements.

- Improved Screening Accuracy: Optimized surface patterns ensure precise material separation, minimizing product loss.

- Enhanced Durability: Advanced manufacturing techniques create a product that withstands harsh industrial environments.

These advantages make our backing plates a cost-effective solution for companies seeking to optimize their screening processes.

Company Expertise and Innovation

With over two decades of experience in the metal wire mesh industry, Muto Wire Screen Co., Ltd. has established itself as a trusted provider of industrial screening solutions. Our facility in Anping County, Hebei Province, is equipped with state-of-the-art machinery and a team of skilled engineers who prioritize quality and innovation.

Our commitment to R&D has led to continuous improvements in product design and performance. By staying ahead of industry trends, we ensure that our vibrating screen backing plates meet the evolving needs of modern manufacturing and processing operations.

Proven Performance and Customer Feedback

Many of our clients have reported significant improvements in their screening operations after adopting our backing plates. For example:

- "Since implementing Muto's backing plates, our maintenance costs have decreased by 40% and production efficiency has increased by 25%." – Mineral Processing Plant Manager

- "The durability of these plates has exceeded our expectations, even in our toughest applications." – Construction Materials Supplier

These testimonials highlight the real-world benefits of our products and reinforce our dedication to customer satisfaction.

Implementation and Customization

We offer comprehensive support for integrating our vibrating screen backing plates into existing systems. Our technical team provides:

- Installation guidelines tailored to specific equipment models

- Customization options for size, material, and surface patterns

- On-site consultation services for complex screening requirements

By working closely with our clients, we ensure that our products are perfectly suited to their operational needs, maximizing performance and return on investment.

Environmental and Safety Compliance

Sustainability and safety are core principles in our manufacturing process. Our backing plates are produced using eco-friendly materials and adhere to international safety standards. The design minimizes material waste during operation, contributing to a more sustainable industrial process.

Logistics and Packaging

To accommodate bulk orders, we provide durable packaging solutions that protect the backing plates during transportation. Our logistics network ensures timely delivery to clients worldwide, with options for sea freight, air freight, and land transport depending on customer requirements.

Comprehensive Customer Support

We offer 24/7 technical support and a dedicated customer service team to address any questions or concerns. Our services include:

- Product training sessions for installation and maintenance

- Regular follow-up to ensure optimal performance

- Customized solutions for unique screening challenges

Our goal is to provide a seamless experience from purchase to long-term use, ensuring that clients receive maximum value from our products.

How to Get Started

For more information about our vibrating screen backing plates or to request a custom quote, please visit our website at www.mutoscreen.com or contact us directly at +86-312-8888888. Our sales team is available to discuss your specific requirements and provide expert guidance.

FAQ: Frequently Asked Questions

Q: What materials are used in the manufacturing of your vibrating screen backing plates?

A: We use high-strength steel and polyurethane materials, which offer excellent wear resistance and durability. The choice of material depends on the specific application requirements.

Q: Can the backing plates be customized to fit different screen sizes?

A: Yes, we offer customized solutions to ensure our products are compatible with various screen frame configurations. Please contact our technical team for detailed specifications.

Q: How do your backing plates improve screening efficiency?

A: Our plates are designed with optimized surface patterns that enhance material flow and reduce clogging. This leads to more efficient separation and higher throughput rates.

Q: What kind of after-sales support do you provide?

A: We offer comprehensive after-sales services, including technical consultations, installation guidance, and regular maintenance support to ensure long-term performance.

Conclusion

Investing in high-quality vibrating screen backing plates is essential for optimizing industrial screening processes. Muto Wire Screen Co., Ltd. provides durable, efficient, and customizable solutions that address the unique challenges faced by modern manufacturers. Contact us today to learn more about how our products can enhance your operations.