Vibrating Screen Backing Plate - Muto Wire Screen Co., Ltd.|Enhancing Efficiency&Durability

Vibrating Screen Backing Plate: Enhancing Efficiency in Industrial Sieving Systems

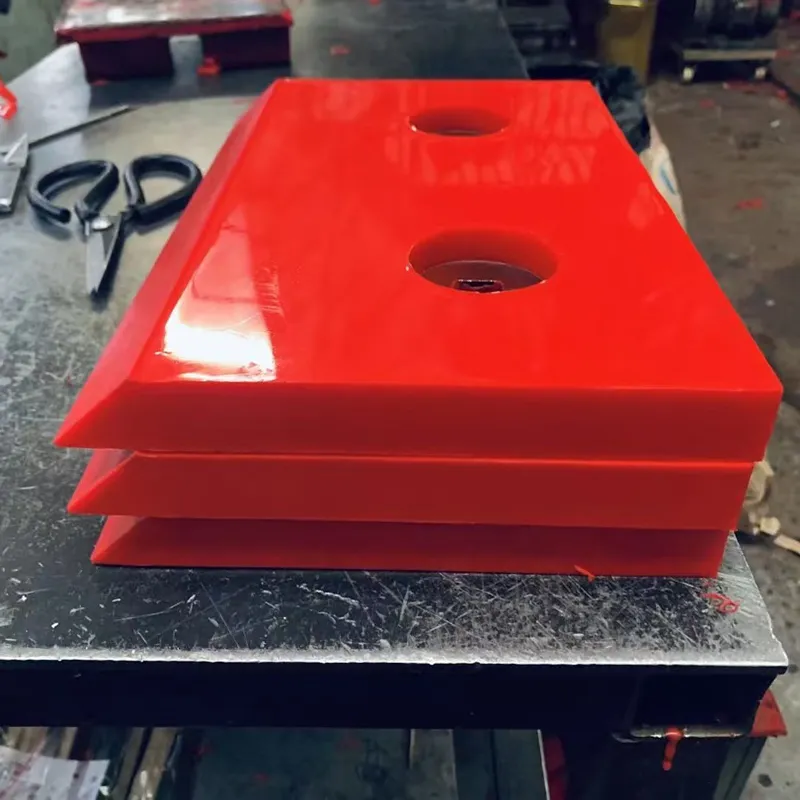

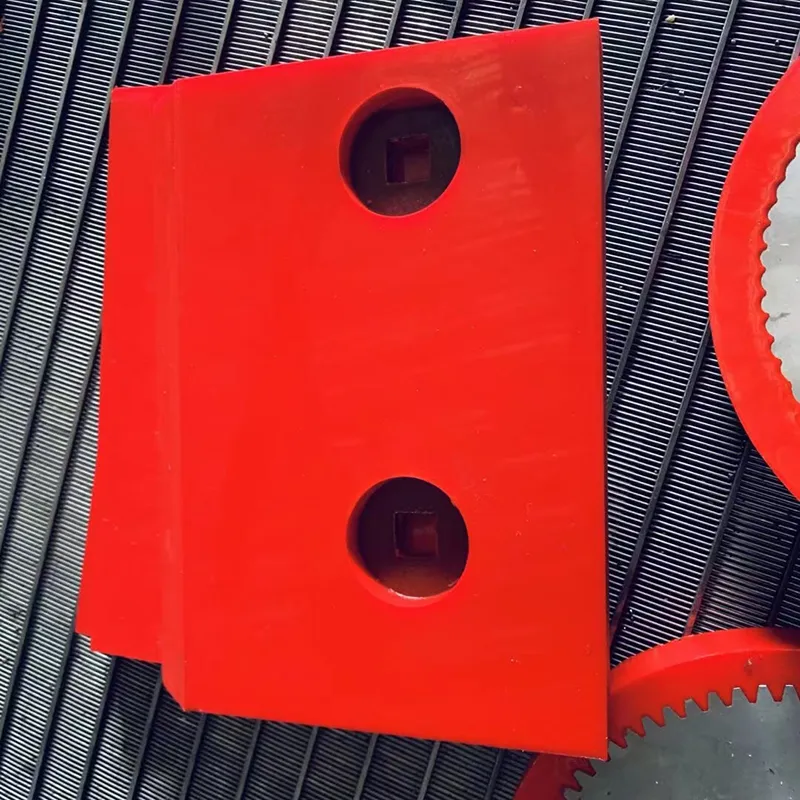

The Vibrating Screen Backing Plate is a critical component in industrial sieving systems, designed to optimize performance and durability. Manufactured by Muto Wire Screen Co., Ltd., this product addresses the challenges of high-stress screening environments while ensuring long-term reliability.

Understanding the Role of Vibrating Screen Backing Plates

Vibrating screen backing plates serve as the structural foundation for screening media, providing support and stability during high-frequency vibrations. These plates are engineered to withstand abrasive materials, extreme temperatures, and continuous operation, making them indispensable in industries such as mining, agriculture, and chemical processing.

Key features include:

- High wear resistance due to advanced material composition

- Customizable designs to fit various screen models

- Enhanced vibration transmission efficiency

- Corrosion-resistant coatings for extended lifespan

Market Demand and Industry Challenges

The global screening equipment market is projected to grow significantly due to increasing demand for efficient material separation solutions. However, traditional backing plates often face issues such as:

- Fracture under prolonged heavy-duty use

- Reduced screening accuracy due to material deformation

- High maintenance costs from frequent replacements

Muto Wire Screen Co., Ltd. addresses these challenges through innovative engineering. Our Vibrating Screen Backing Plate combines advanced polymer technology with precision manufacturing to deliver superior performance in demanding environments.

Technical Specifications and Material Advantages

Key technical parameters of the Vibrating Screen Backing Plate include:

| Parameter | Specification |

|---|---|

| Material | Polyurethane composite with stainless steel reinforcement |

| Thickness | 8-12mm (customizable) |

| Load Capacity | Up to 500kg/m² |

| Operating Temperature Range | -20°C to 80°C |

The polyurethane composition offers exceptional abrasion resistance, while the stainless steel framework ensures structural integrity. This combination reduces maintenance frequency by up to 60% compared to conventional metal plates.

Applications Across Industries

Our Vibrating Screen Backing Plate is widely used in:

- Mineral Processing: Enhancing efficiency in ore screening operations

- Agri-Food Industry: Ensuring precise particle separation in grain and seed processing

- Chemical Manufacturing: Maintaining product purity in powder and granule screening

- Recycling Facilities: Improving material sorting accuracy in waste management

Case Study: A leading mining company reported a 35% increase in screening efficiency after replacing standard backing plates with Muto's solution, reducing downtime by 25%.

Company Expertise and Innovation

With over 15 years of experience in wire mesh and screening solutions, Muto Wire Screen Co., Ltd. has established itself as a leader in industrial screening technology. Our R&D team continuously innovates to meet evolving industry demands, resulting in:

- Patented vibration-damping design

- ISO 9001-certified manufacturing processes

- Customizable solutions for unique application requirements

Our commitment to quality is reflected in our rigorous testing procedures, which include:

- 24/7 vibration stress testing

- Corrosion resistance evaluation

- Material hardness and tensile strength analysis

Performance Benefits and Customer Testimonials

Users of our Vibrating Screen Backing Plate consistently report:

- Extended service life of 3-5 years under heavy usage

- Improved screening accuracy by 20-30%

- Reduced operational costs through minimal maintenance

"Since implementing Muto's backing plates, our production efficiency has increased by 40%. The durability and precision have exceeded our expectations."

- John D., Plant Manager at XYZ Mining Co.

Implementation and Customization Options

We offer comprehensive solutions tailored to your specific requirements:

- Custom plate dimensions and shapes

- Special coatings for extreme environments

- Integration with existing screening systems

- Technical support for installation and optimization

Our team works closely with clients to analyze their screening processes and recommend the optimal backing plate configuration. This includes:

- Vibration frequency analysis

- Material flow pattern simulation

- Cost-benefit evaluation

Environmental and Safety Compliance

All Vibrating Screen Backing Plates comply with international safety standards, including:

- OSHA compliance for industrial equipment

- RoHS directive for hazardous substance restrictions

- CE certification for European market access

The polyurethane material is also environmentally friendly, with recyclable components and low VOC emissions during manufacturing.

Logistics and Packaging Solutions

We provide robust packaging designed for industrial shipping:

- Custom wooden crates for large quantities

- Moisture-proof inner packaging

- Clear labeling for easy identification

Our logistics partners ensure timely delivery worldwide, with options for:

- Sea freight for bulk orders

- Air freight for urgent shipments

- Customized delivery schedules

Comprehensive Customer Support

Muto Wire Screen Co., Ltd. offers dedicated support throughout the product lifecycle:

- 24/7 technical assistance

- On-site installation guidance

- Regular maintenance check-ups

- Warranty coverage for 12-24 months

Our customer service team is available via:

- Email: sales@mutoscreen.com

- Phone: +86-312-555-6666

- Online Chat: Visit our website

Conclusion

The Vibrating Screen Backing Plate from Muto Wire Screen Co., Ltd. delivers unmatched performance and reliability for industrial screening applications. With its advanced design, durable materials, and comprehensive support services, this product is an essential investment for any business seeking to optimize operational efficiency and reduce maintenance costs.

Frequently Asked Questions

What materials are used in the Vibrating Screen Backing Plate?

The backing plate is made from a high-performance polyurethane composite reinforced with stainless steel, offering excellent wear resistance and structural integrity.

Can the backing plates be customized?

Yes, we offer customized solutions for specific dimensions, shapes, and special requirements to match your screening equipment.

What is the typical lifespan of the backing plate?

Under normal operating conditions, the backing plate can last 3-5 years, depending on usage intensity and material characteristics.

Are there any environmental certifications?

Our products comply with RoHS and CE standards, ensuring they meet international environmental and safety regulations.

How can I get technical support?

Contact our technical team via email at sales@mutoscreen.com or use the live chat feature on our website.