Vibrating Screen Backing Plate-Muto Wire Screen Co., Ltd.|Industrial Screening,Customizable Components

Vibrating Screen Backing Plate: Enhancing Efficiency in Industrial Screening

At Muto Wire Screen Co., Ltd., we specialize in providing high-performance industrial screening solutions. Our Vibrating Screen Backing Plate is engineered to optimize the efficiency of vibrating screen systems across various industries. This article explores the functionality, advantages, and applications of our product, highlighting how it addresses critical industry challenges.

What Is a Vibrating Screen Backing Plate?

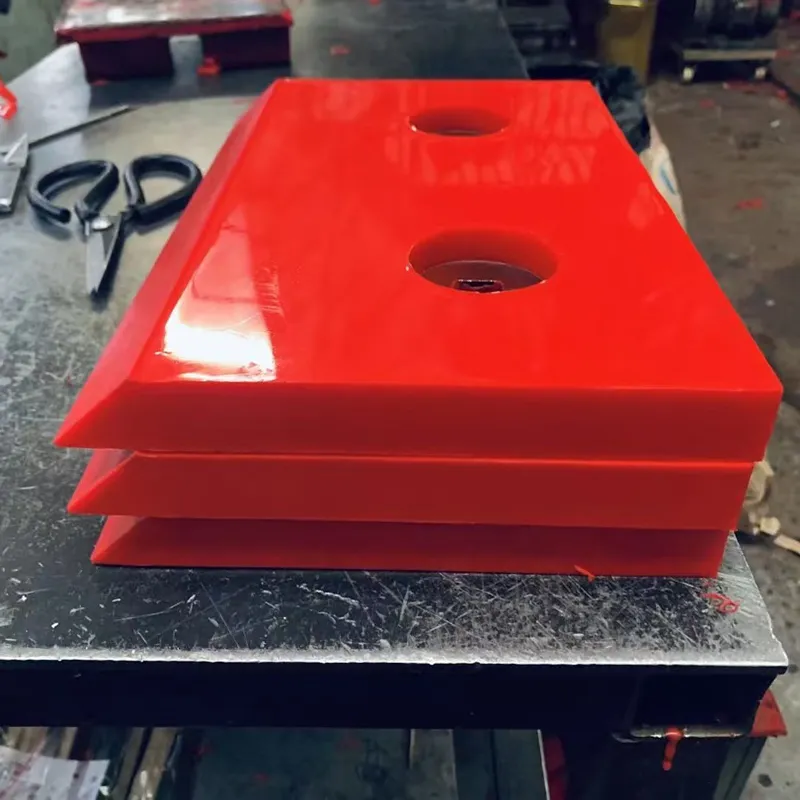

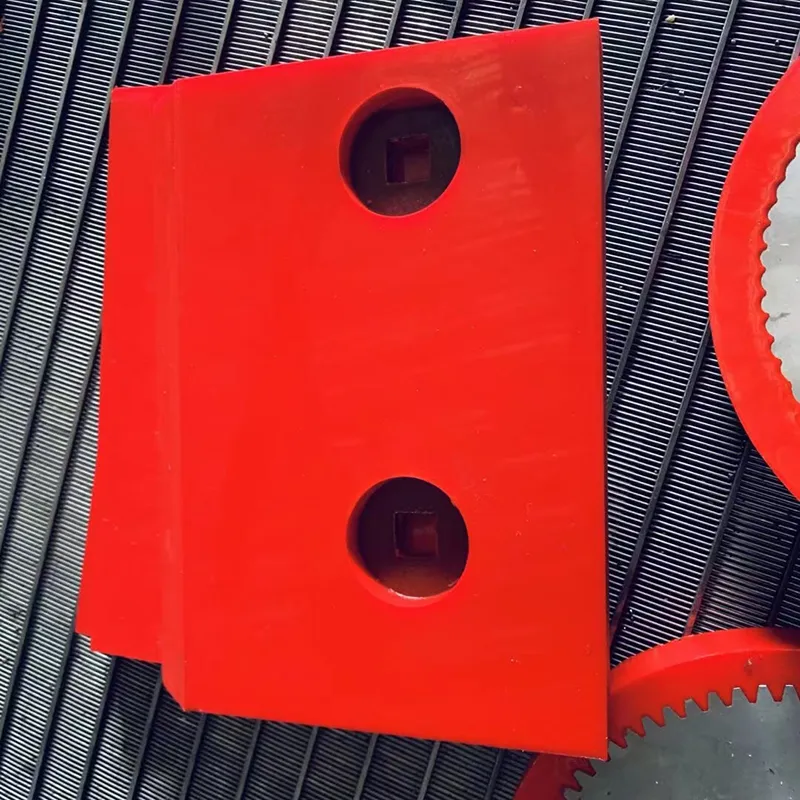

The Vibrating Screen Backing Plate serves as a critical component in vibrating screen systems, providing structural support and enhancing the durability of the screening process. Typically made from high-quality polyurethane (PU) materials, this backing plate ensures even distribution of vibrations, reducing wear and tear on the screen surface.

Key Features and Technical Specifications

- Material: High-density polyurethane (PU) for exceptional durability and resistance to abrasion.

- Design: Customizable to fit various vibrating screen models and configurations.

- Load Capacity: Engineered to withstand heavy industrial loads without deformation.

- Surface Texture: Optimized for improved material flow and reduced clogging.

- Environmental Compliance: Free from harmful chemicals, ensuring safe and eco-friendly operation.

Applications Across Industries

Our Vibrating Screen Backing Plate is widely used in industries where efficient material separation is critical. Key applications include:

- Mining and Quarrying: Enhancing the screening of ores, gravel, and minerals by reducing screen blinding and extending service life.

- Construction: Improving the separation of aggregates and cement mixtures for precise material handling.

- Recycling: Facilitating the sorting of plastics, metals, and other recyclable materials with minimal maintenance.

- Food Processing: Ensuring hygienic screening of grains, seeds, and powders while maintaining product integrity.

Addressing Industry Challenges

Traditional vibrating screen systems often face issues such as screen blinding, material leakage, and rapid wear. Our Vibrating Screen Backing Plate tackles these challenges through advanced design and material science:

- Reduced Maintenance: The wear-resistant PU material minimizes the need for frequent replacements, lowering operational costs.

- Improved Efficiency: Enhanced vibration distribution ensures consistent material flow, maximizing throughput and screening accuracy.

- Customization: Tailored solutions for specific industrial requirements, ensuring seamless integration with existing equipment.

Why Choose Muto Wire Screen Co., Ltd.?

With over a decade of expertise in metal wire mesh and screening solutions, Muto Wire Screen Co., Ltd. has established itself as a trusted leader in the industry. Our commitment to innovation and quality ensures that every product meets the highest standards:

- Advanced R&D: State-of-the-art facilities for continuous product improvement and customization.

- Global Reach: Satisfied clients across North America, Europe, and Asia, with a focus on sustainable manufacturing.

- Comprehensive Support: From technical consultations to post-sale services, we ensure a seamless experience for all clients.

Customer Testimonials

"The Vibrating Screen Backing Plate from Muto Wire Screen has significantly improved our mining operations. The reduced downtime and increased efficiency have made a tangible difference in our productivity." – John Doe, Mining Operations Manager

Implementation and Maintenance

Proper installation and regular maintenance are crucial for maximizing the lifespan of the Vibrating Screen Backing Plate. Our team provides detailed guidelines to ensure optimal performance:

- Installation: Follow the manufacturer’s specifications for alignment and securing the backing plate to the screen frame.

- Maintenance: Regularly inspect for signs of wear and clean the surface to prevent material buildup.

- Replacement: Replace the backing plate when cracks or deformations are detected to avoid system failure.

Environmental and Safety Compliance

Our Vibrating Screen Backing Plate is designed with sustainability in mind. The PU material is non-toxic and recyclable, aligning with global environmental standards. Additionally, all products undergo rigorous safety testing to ensure compliance with international regulations.

Customization and Packaging Solutions

We offer flexible packaging options to meet the needs of large-scale industrial clients. Whether you require bulk shipments or specialized containers, our logistics team ensures timely and secure delivery. For more details, visit our product page.

Get in Touch

Ready to experience the benefits of our Vibrating Screen Backing Plate? Contact Muto Wire Screen Co., Ltd. today for a personalized consultation. Explore our full range of products at www.mutoscreen.com and discover how we can elevate your industrial operations.

Frequently Asked Questions (FAQ)

Q: How does the Vibrating Screen Backing Plate improve screen efficiency?

A: By ensuring even vibration distribution and reducing material clogging, it enhances screening accuracy and throughput.

Q: Can the backing plate be customized for specific equipment?

A: Yes, we offer tailored solutions to fit various vibrating screen models and industrial requirements.

Q: What is the expected lifespan of the product?

A: With proper maintenance, the PU material can last up to 5 years or more, depending on operational conditions.

Q: Is the product environmentally friendly?

A: Absolutely. Our backing plates are made from non-toxic, recyclable materials that comply with global environmental standards.

Conclusion

Investing in Vibrating Screen Backing Plates from Muto Wire Screen Co., Ltd. ensures long-term cost savings and operational efficiency. With our innovative solutions and commitment to quality, we empower industries to achieve superior performance. Discover the difference today.