- Comprehensive overview of vibrating screen sieve

technology - Critical performance metrics through material testing data

- Technical advantages of modern screening systems

- Manufacturer capability comparison analysis

- Customized sieve bend screen design solutions

- Real-world application case studies

- Future developments in screening technology

(vibrating screen sieve)

The Essential Guide to Vibrating Screen Sieves

Modern vibrating screen sieves form the backbone of material classification across industries ranging from mining to food processing. These dynamic separation systems utilize controlled vibrations to stratify and size bulk materials efficiently. Unlike static screens, vibrating mechanisms prevent material blinding while increasing throughput capacity.

Fundamental operational parameters include vibration frequency (typically 600-3600 RPM), amplitude (1-10mm), and screen angle (15°-25°). These variables determine material retention time and separation accuracy. Industrial applications process between 50-2500 tons per hour depending on screen dimensions and material density.

Data-Driven Performance Optimization

Material testing provides critical insights for sieve optimization. Laboratory analysis reveals that particle distribution directly affects screening efficiency:

- Materials with 60-80% near-size particles require 30% longer retention

- Moisture content exceeding 5% reduces efficiency by 15-40%

- Adhesive materials require minimum 50% increased vibration amplitude

Precision monitoring systems now track real-time performance metrics including mesh wear rates, material bed depth, and vibration consistency. This data enables predictive maintenance scheduling before efficiency drops below 85% benchmark levels.

Engineering Advantages in Modern Systems

Contemporary vibrating screens incorporate multiple technological improvements over traditional designs:

- Modular panel systems reduce replacement downtime by 70%

- Polyurethane surfaces extend service life 3x longer than wire mesh

- Balanced elliptical vibration patterns increase material travel speed by 25%

- Sealed bearing systems withstand contamination in harsh environments

Combined, these innovations deliver 92-97% separation accuracy versus 70-85% in conventional designs while reducing energy consumption up to 45% per ton processed.

Manufacturer Capabilities Comparison

| Manufacturer | Max. Capacity (tph) | Screen Panel Options | Minimum Maintenance | Custom Design Ratio |

|---|---|---|---|---|

| VibroTech Systems | 1,200 | 14 materials | 20,000 hours | 65% of orders |

| Sepro Mineral Systems | 2,500 | 9 materials | 15,000 hours | 40% of orders |

| Metso Outotec | 3,500 | 12 materials | 25,000 hours | 55% of orders |

| Derrick Corporation | 800 | 22 materials | 30,000 hours | 85% of orders |

Market leaders differentiate through proprietary technologies: VibroTech's anti-clogging wave screens reduce pegging incidents by 90%, while Metso's polyweb panels withstand impact forces exceeding 5.7 joules without deformation.

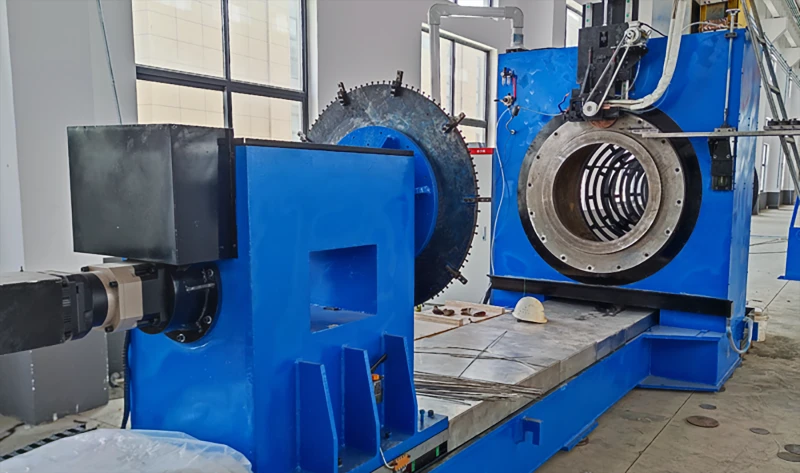

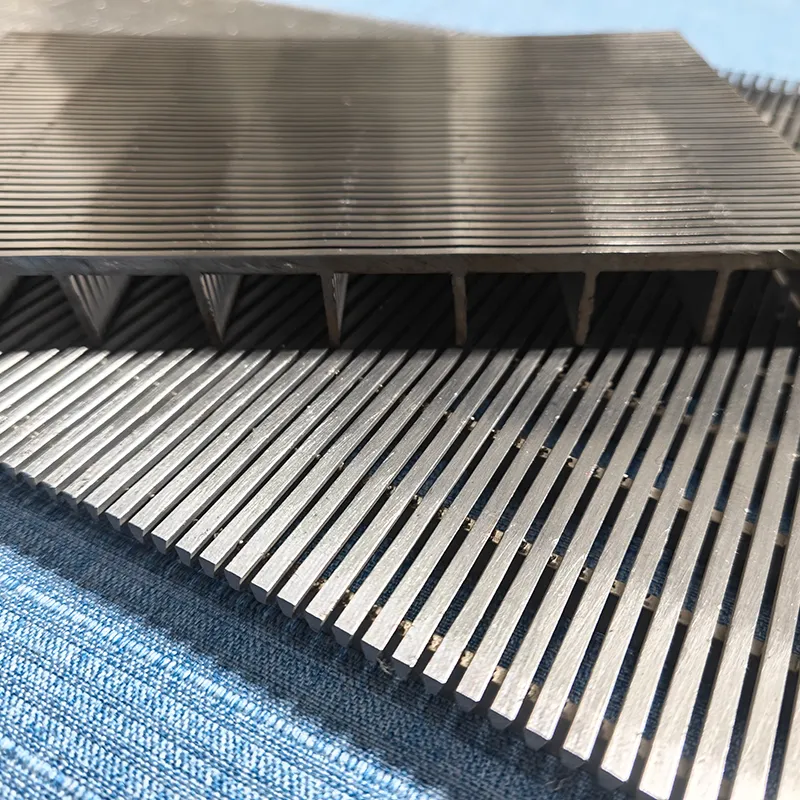

Custom Sieve Bend Screen Engineering

Specialized operations require tailored sieve bend screen designs to address unique material challenges:

- Sloped wedge wire arrangements (45°-70°) prevent fibrous material entanglement

- Graduated aperture sizing compensates for particle stratification issues

- Asymmetric vibration patterns handle extreme density variations

Custom solutions typically implement tiered screening decks with progressively finer openings (e.g., 100mm → 50mm → 25mm). Stainless steel screen surfaces remain standard, though ceramic-coated options extend service life 2.5x in abrasive environments like iron ore processing.

Industrial Application Case Studies

Aggregate Processing Plant: A Canadian quarry replaced traditional wire mesh with polyurethane modular panels, achieving:

- 32% increased material throughput (850 → 1,122 tph)

- Reduced replacement frequency from quarterly to every 14 months

- 98.7% separation accuracy for 1" minus product specifications

Food Processing Facility: Adjustable-frequency vibrating screens implemented in grain sorting operation resolved inconsistent sizing issues, resulting in:

- 17% reduction in product waste

- Compliance with 99.5% purity requirements for export certification

- Recovery of $550,000 worth of previously discarded premium product annually

Next-Generation Sieve Bend Screen Evolution

Screening technology continues advancing toward smarter operations. Embedded IoT sensors now monitor real-time vibration signatures, alerting operators to unbalanced loads or bearing degradation before catastrophic failure occurs. Data analytics predict optimal screen maintenance intervals within ±5% accuracy.

Material handling industries show increasing preference for modular sieve bend screen designs enabling rapid configuration changes between production runs. Simultaneously, composite screen surfaces combining tungsten carbide inserts with polymer substrates demonstrate unprecedented wear resistance in pilot tests. These innovations point toward screening installations requiring less than 8 hours quarterly maintenance while maintaining 95%+ operational efficiency.

(vibrating screen sieve)

FAQS on vibrating screen sieve

Q: How does a vibrating screen sieve work?

A: A vibrating screen sieve uses vibratory motion to separate materials by size. The vibrations cause smaller particles to pass through the mesh, while larger particles move across the surface for discharge.

Q: What industries commonly use vibrating screen sieves?

A: Industries like mining, construction, agriculture, and recycling use vibrating screen sieves for tasks such as sorting aggregates, separating minerals, and processing grains or waste materials.

Q: What factors influence sieve bend screen design?

A: Key factors include feed flow rate, material type, desired separation efficiency, and screen curvature. The design optimizes particle stratification and minimizes blinding for wet or slurry applications.

Q: How to maintain a sieve bend screen for longevity?

A: Regularly inspect for wear, clean blockages, and replace damaged panels. Proper alignment and monitoring of feed consistency also reduce wear and ensure efficient operation.

Q: What distinguishes a sieve bend screen from a standard vibrating screen?

A: Sieve bend screens use a curved surface and gravity-driven flow for wet separation, while vibrating screens rely on mechanical vibrations for dry or semi-dry material sorting.