Wedge Wire Screen - Muto Wire Screen Co., Ltd.|High-Efficiency Filtration, Custom Solutions

Wedge Wire Screen: High-Efficiency Filtration Solution for Industrial Applications

As a leading manufacturer in the metal wire mesh industry, Muto Wire Screen Co., Ltd. specializes in providing innovative filtration solutions. Our Wedge Wire Screen is designed to meet the demanding requirements of modern industrial applications, offering superior performance and reliability. This article explores the features, benefits, and applications of our wedge wire screen, highlighting how it can enhance your production processes.

What is Wedge Wire Screen?

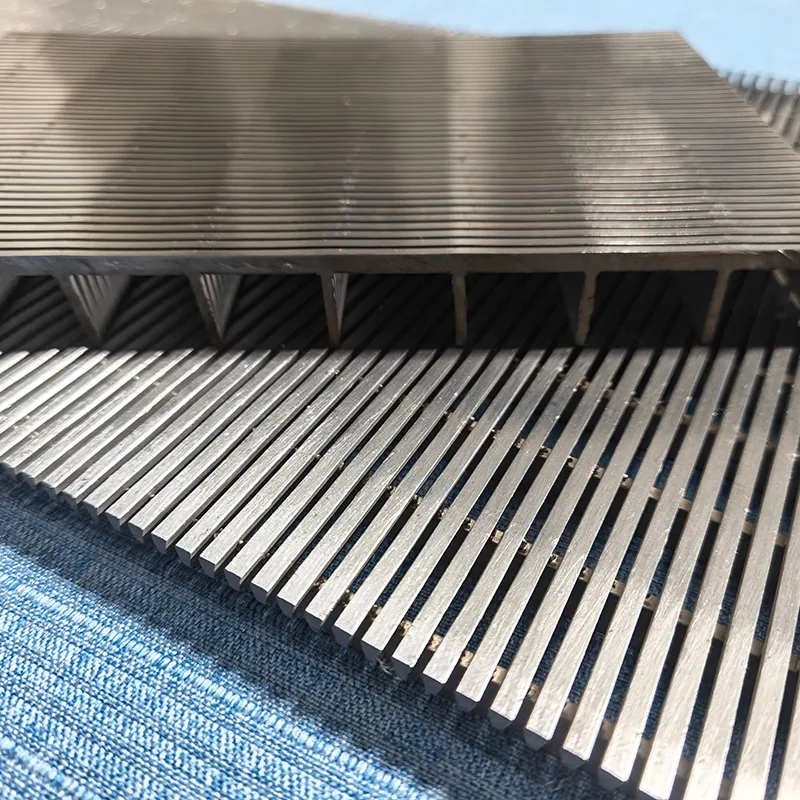

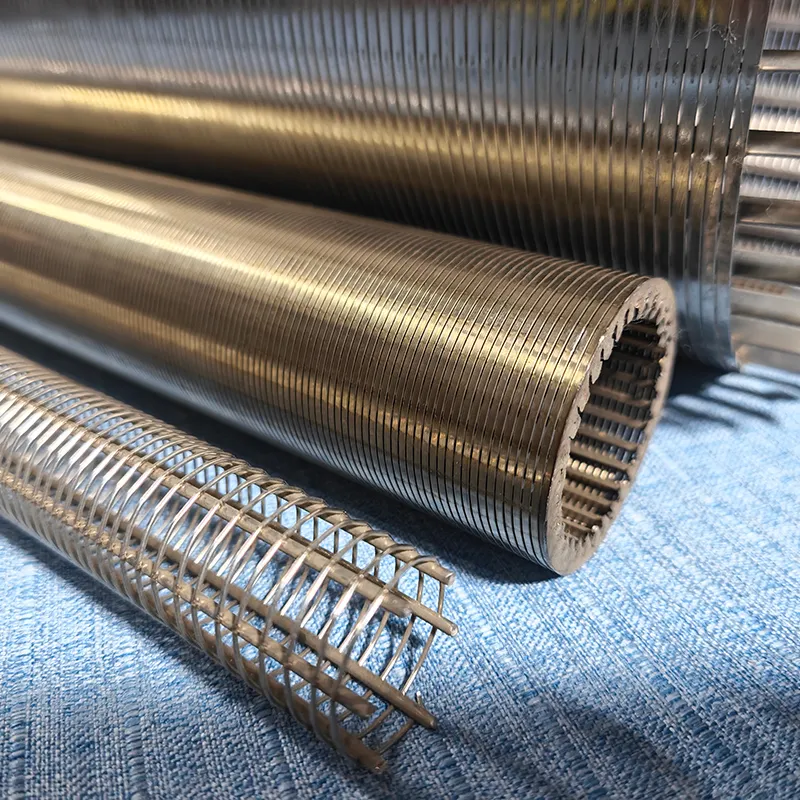

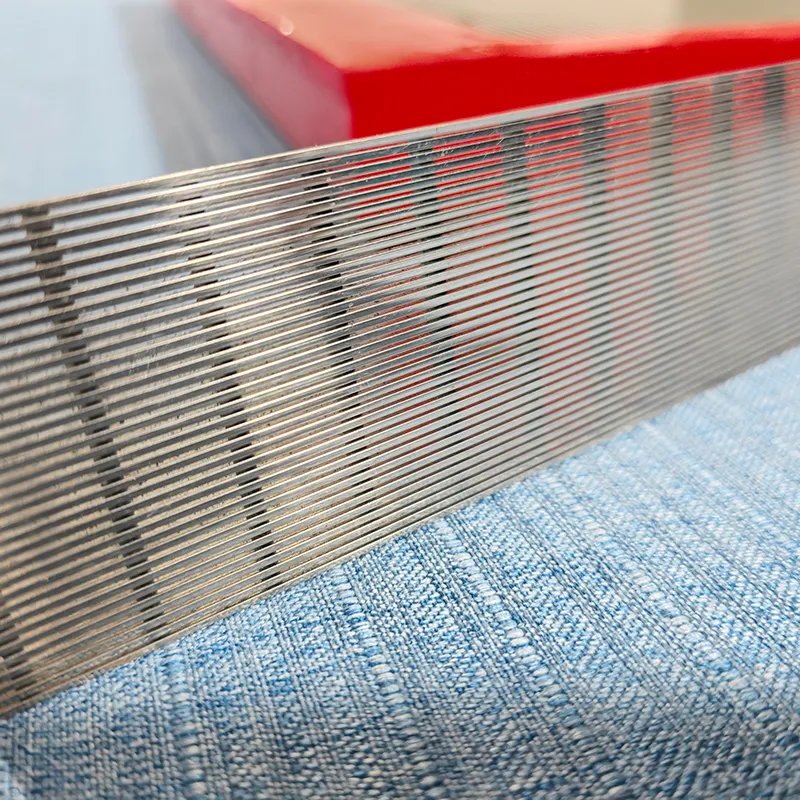

The Wedge Wire Screen is a specialized filtration medium characterized by its unique design. Unlike traditional wire mesh, it features a V-shaped cross-section that provides a larger open area while maintaining structural integrity. This design allows for efficient fluid flow and effective particle retention, making it ideal for a wide range of industrial applications.

Key Features and Technical Specifications

- Material: High-quality stainless steel, carbon steel, or other custom alloys

- Open Area: Up to 35% (depending on configuration)

- Wire Diameter: 0.5mm - 5.0mm

- Slot Width: 0.1mm - 2.0mm

- Surface Finish: Polished, electropolished, or coated as required

Why Choose Our Wedge Wire Screen?

Our Wedge Wire Screen offers several advantages over conventional filtration systems:

- High Filtration Efficiency: The V-shaped design ensures minimal pressure drop while maintaining excellent particle retention.

- Durability: Constructed from premium materials, our screens resist corrosion, wear, and deformation under harsh operating conditions.

- Customization: We offer tailored solutions to meet specific application requirements, including different slot sizes, materials, and configurations.

- Easy Maintenance: The robust design minimizes clogging and simplifies cleaning, reducing downtime and maintenance costs.

Industries and Applications

The Wedge Wire Screen is widely used in various industries, including:

- Chemical Processing: For separating solids from liquids in reactors, filters, and separators.

- Food and Beverage: In brewing, dairy processing, and juice clarification to remove impurities.

- Pharmaceuticals: For precise filtration of active ingredients and sterile solutions.

- Water Treatment: As a pre-filter in municipal and industrial water purification systems.

- Oil and Gas: For sand control in well screens and fluid separation in processing units.

Market Demand and Industry Challenges

The global filtration market is experiencing rapid growth, driven by increasing demand for efficient and sustainable solutions. However, traditional filtration systems often struggle with issues such as clogging, low flow rates, and frequent maintenance. Our Wedge Wire Screen addresses these challenges by providing a durable, high-performance alternative that reduces operational costs and improves process efficiency.

About Muto Wire Screen Co., Ltd.

With over a decade of expertise in the metal wire mesh industry, Muto Wire Screen Co., Ltd. has established itself as a trusted supplier of high-quality filtration products. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every Wedge Wire Screen meets the highest standards of performance and reliability.

Product Performance and Customer Testimonials

Our Wedge Wire Screen has been successfully deployed in numerous industrial settings, delivering measurable improvements in efficiency and cost savings. One of our clients, a leading chemical manufacturer, reported a 40% reduction in maintenance costs after switching to our filtration solution. Another customer in the food industry noted a significant improvement in product quality due to the screen's precise particle retention capabilities.

Usage Guidelines and Implementation

To maximize the performance of our Wedge Wire Screen, we recommend the following:

- Installation: Ensure proper alignment and secure mounting to prevent leakage or damage.

- Operation: Monitor flow rates and pressure differentials regularly to detect any signs of clogging.

- Maintenance: Clean the screen periodically using recommended methods to maintain optimal performance.

For complex applications, our technical team can provide customized implementation plans and on-site support.

Safety and Compliance

All our Wedge Wire Screens comply with international safety and environmental standards. The materials used are non-toxic, corrosion-resistant, and suitable for use in sensitive environments. We also provide detailed safety data sheets (SDS) and compliance certificates upon request.

Packaging and Shipping

We offer robust packaging solutions to ensure the safe delivery of our Wedge Wire Screens. Each unit is carefully wrapped in protective film and secured in sturdy wooden crates. For bulk orders, we can arrange custom packaging to meet your specific logistics requirements. Our global shipping network ensures timely delivery to customers worldwide.

Customer Support and After-Sales Service

At Muto Wire Screen Co., Ltd., we are committed to providing exceptional customer support. Our dedicated team offers:

- Technical Consultation: Expert advice on product selection, installation, and troubleshooting.

- Warranty: A comprehensive warranty covering defects in materials and workmanship.

- Custom Solutions: Tailored filtration systems designed to meet your unique operational needs.

Contact Us

Ready to experience the benefits of our Wedge Wire Screen? Visit our product page to learn more or contact us directly at sales@mutoscreen.com for a personalized quote. Our team is here to help you find the perfect filtration solution for your business.

FAQ

Q: What materials are available for the Wedge Wire Screen?

A: We offer stainless steel, carbon steel, and other custom alloys to suit different application requirements.

Q: Can the Wedge Wire Screen be customized?

A: Yes, we provide tailored solutions including specific slot sizes, wire diameters, and configurations.

Q: How long does it take to receive an order?

A: Delivery times vary depending on the order size and destination. Please contact our sales team for detailed information.

Conclusion

The Wedge Wire Screen from Muto Wire Screen Co., Ltd. offers a reliable and efficient solution for industrial filtration. With its advanced design, durability, and customization options, it helps businesses reduce costs, improve productivity, and meet environmental standards. Discover the difference today by visiting our product page.