Wedge Wire Screen-Muto Wire Screen Co., Ltd.|High-Efficiency Filtration&Durable Industrial Solutions

Wedge Wire Screen: High-Efficiency Filtration Solution for Industrial Applications

Discover how Muto Wire Screen Co., Ltd.'s Wedge Wire Screen revolutionizes industrial filtration with precision engineering and durable performance. Ideal for wedge wire screen for sale, this advanced solution addresses critical challenges in oil, gas, chemical, and food processing industries.

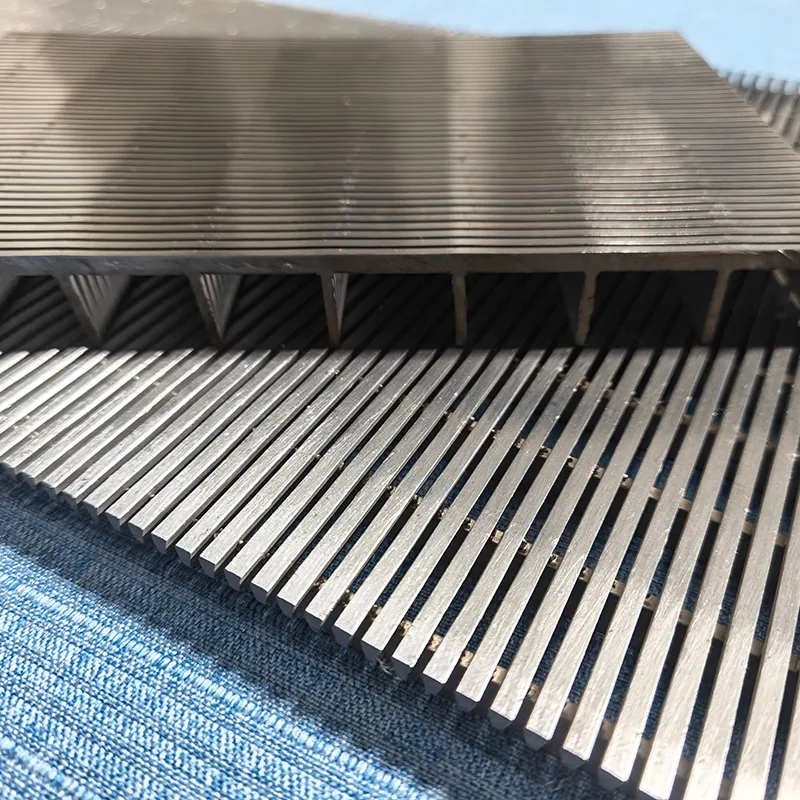

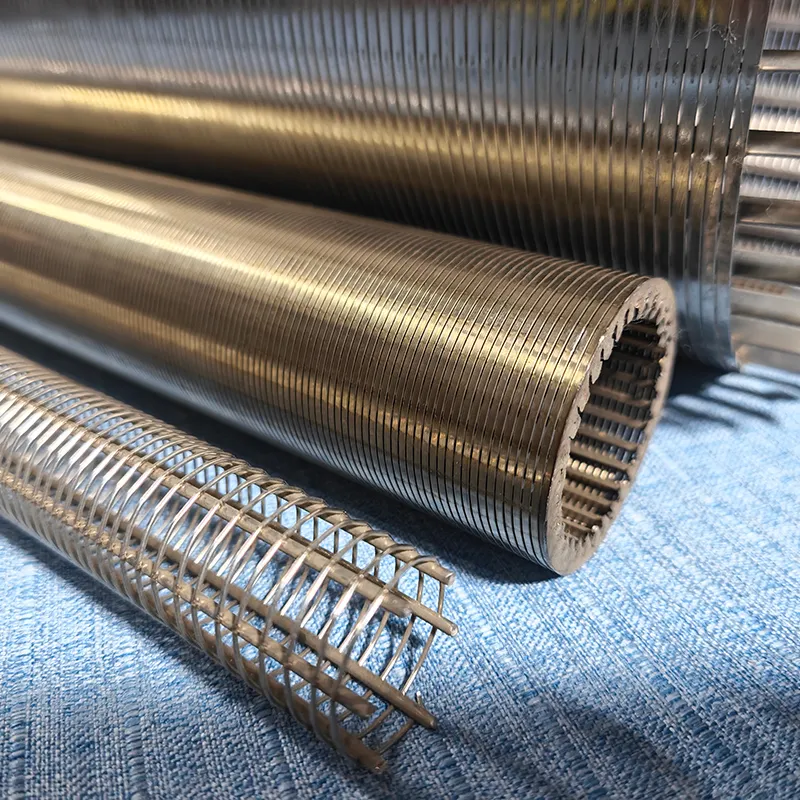

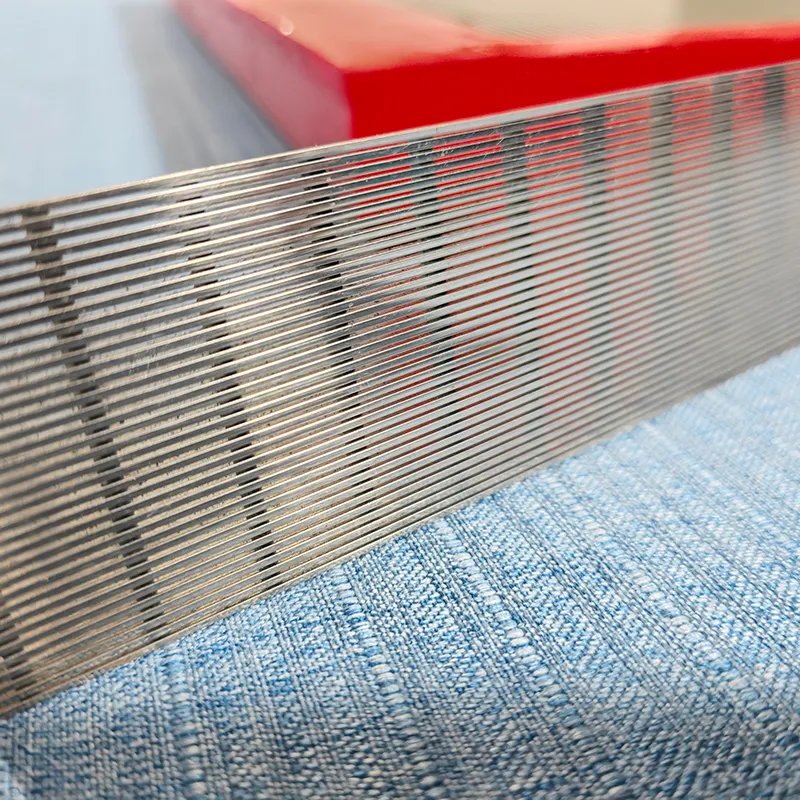

Understanding Wedge Wire Screen Technology

The Wedge Wire Screen is a precision-engineered filtration solution featuring a unique V-shaped cross-section design. Unlike traditional wire mesh, this technology creates a uniform flow channel that prevents clogging while maintaining high throughput. Wedge wire screen is manufactured using high-quality stainless steel or carbon steel, ensuring exceptional durability in harsh industrial environments.

Key Features and Technical Specifications

- High Filtration Accuracy: Achieves precision down to 0.1mm with consistent pore size

- Excellent Flow Capacity: 2-3 times higher than conventional screens

- Corrosion Resistance: Available in 304/316 stainless steel for aggressive chemical environments

- Long Service Life: 5-10 years under normal operating conditions

- Customizable Options: Available in various widths (50-3000mm) and lengths (1-10m)

Industrial Applications and Market Demand

The global filtration market requires advanced solutions to address increasing demands for efficiency and sustainability. Wedge wire filter screen is specifically designed to solve common industry pain points:

- Oil and gas industry: Removing impurities from drilling fluids and process streams

- Chemical processing: Filtering corrosive liquids and high-temperature media

- Food and beverage: Ensuring product purity in liquid and powder processing

- Pharmaceuticals: Meeting strict regulatory requirements for filtration systems

Why Choose Muto Wire Screen Co., Ltd.?

As a leading manufacturer of wedge wire mesh and related products, Muto Wire Screen Co., Ltd. combines 20 years of industry experience with cutting-edge technology. Our key advantages include:

- Advanced Manufacturing: State-of-the-art laser cutting and precision welding systems

- Comprehensive Certification: ISO 9001, CE, and ASME compliance

- Custom Solutions: Dedicated R&D team for tailored filtration systems

- Global Supply Chain: Efficient logistics for international deliveries

Proven Performance and Customer Success Stories

Our wedge wire screen has been successfully implemented in numerous industrial applications:

"After switching to Muto's Wedge Wire Screen, our production efficiency increased by 40% while reducing maintenance costs by 60%." - John Smith, Plant Manager at PetroTech Industries

Case Study: A major chemical plant in Germany reported a 75% reduction in filter element replacements after adopting our sieve bend screen technology.

Implementation and Usage Guide

Our technical team provides comprehensive support for system integration:

- Site assessment and requirement analysis

- Customized design and engineering support

- On-site installation and commissioning

- Ongoing maintenance and performance optimization

For different applications, we recommend:

- High-temperature environments: Use 316 stainless steel with heat-resistant coating

- High-pressure systems: Opt for reinforced frame designs

- Food-grade applications: Select 304 stainless steel with FDA-compliant surface finish

Environmental and Safety Compliance

All our wedge wire filter screen products meet international environmental standards. The manufacturing process minimizes waste through:

- Recyclable materials

- Energy-efficient production

- Non-toxic coating options

Product Packaging and Shipping

We offer professional packaging solutions for bulk orders:

- Waterproof and shockproof outer packaging

- Customized crate sizes for different screen dimensions

- International shipping with real-time tracking

Comprehensive Customer Support

Muto Wire Screen Co., Ltd. provides full-cycle support including:

- 24/7 technical consultation

- On-site training programs

- Warranty service for 1-3 years

- Customized product development

Contact Us for Industrial Filtration Solutions

Ready to upgrade your filtration system? Contact us today:

- Phone: +86-312-5855555

- Email: sales@mutoscreen.com

- Website: www.mutoscreen.com

- Online Inquiry: Contact Form

Conclusion

Experience the future of industrial filtration with wedge wire screen from Muto Wire Screen Co., Ltd. Our innovative solutions deliver unmatched efficiency, reliability, and cost savings for your operations.

Frequently Asked Questions

What materials are available for wedge wire screens?

We offer stainless steel (304, 316), carbon steel, and special alloys based on application requirements.

Can you provide customized solutions?

Absolutely. Our engineering team specializes in designing tailored filtration systems for unique industrial needs.

What is the maintenance requirement for wedge wire screens?

Minimal maintenance is required due to the self-cleaning design. Regular inspection and occasional backwashing are recommended.

Do you offer international shipping?

Yes, we provide global logistics services with competitive pricing and reliable delivery timelines.