Wedge Wire Screen: High-Efficiency Filtration Solution for Industrial Applications

As a leading manufacturer in the wire mesh industry, Muto Wire Screen Co., Ltd. specializes in producing high-quality wedge wire screen solutions for diverse industrial applications. Our wedge wire filter screen combines advanced engineering with durable materials to deliver exceptional performance in demanding environments. This article explores the technical specifications, applications, and benefits of our wedge wire screen, highlighting why it has become a preferred choice for industries worldwide.

Understanding Wedge Wire Screen Technology

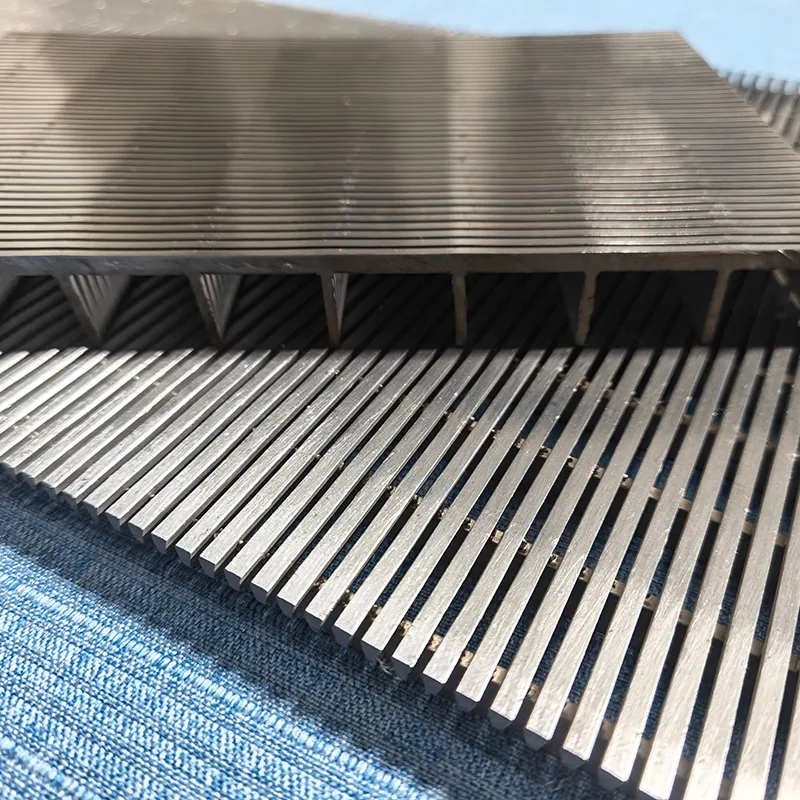

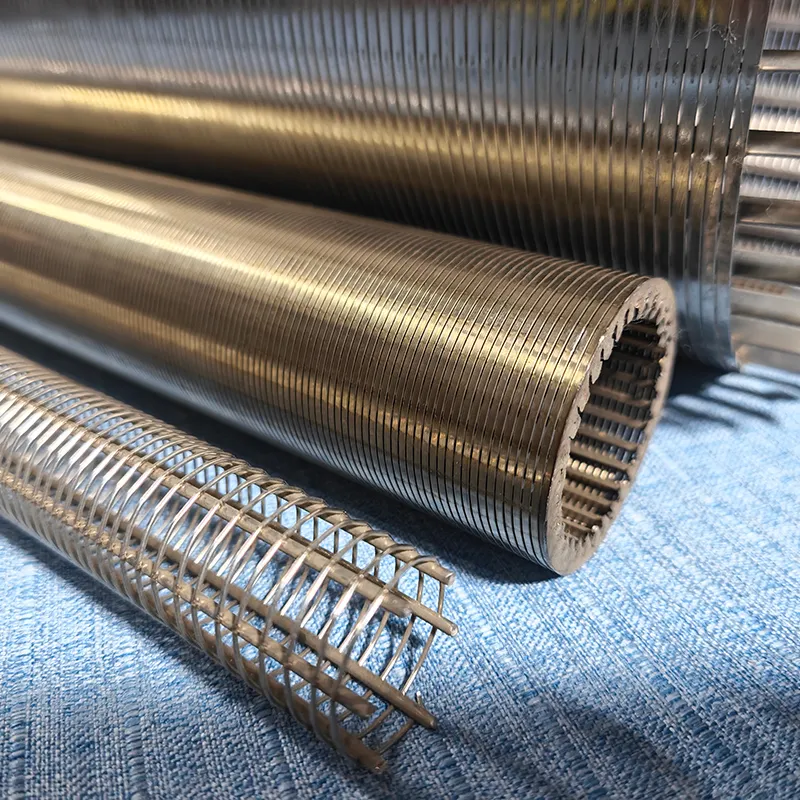

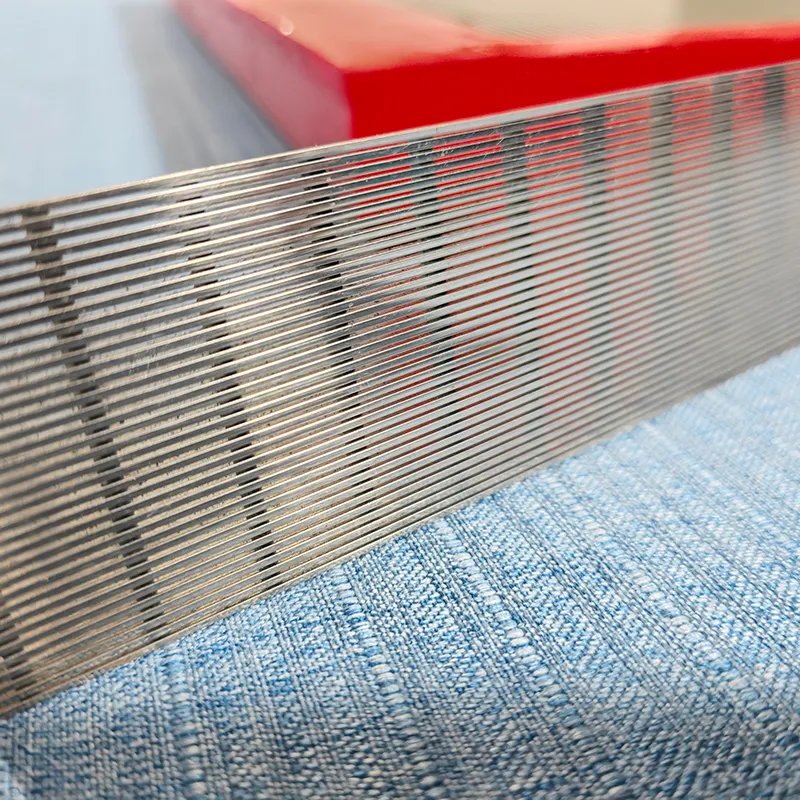

The wedge wire screen is a specialized type of wedge wire mesh designed to provide high filtration efficiency and structural integrity. Unlike traditional woven wire screens, the wedge-shaped profile of the wire creates a uniform open area, allowing for optimal flow rates while preventing clogging. This unique design makes it ideal for applications requiring precise particle separation and high throughput.

Our wedge wire filter screen is manufactured using premium-grade stainless steel, carbon steel, or other corrosion-resistant materials, ensuring longevity in harsh environments. The precision engineering of the wedge wire screen guarantees consistent performance, even under high-pressure conditions.

Key Features and Technical Specifications

1. High Open Area: The wedge wire design maximizes the open area, reducing flow resistance and improving filtration efficiency. 2. Excellent Strength: The interlocking wedge-shaped wires provide superior structural rigidity, preventing deformation under heavy loads. 3. Customizable Dimensions: Available in various widths, lengths, and thicknesses to meet specific application requirements. 4. Corrosion Resistance: Coated or stainless steel options ensure durability in corrosive environments. 5. Easy Maintenance: The smooth surface minimizes material buildup, simplifying cleaning and reducing downtime.

For detailed specifications, visit our product page to explore the full range of wedge wire screen solutions.

Industrial Applications of Wedge Wire Screen

The versatility of wedge wire screen makes it suitable for a wide range of industries, including:

- Mineral Processing: Used in sieve bend screen systems for efficient classification of ores and minerals.

- Chemical Industry: Ideal for filtering viscous liquids and slurries in chemical reactors and separation processes.

- Food and Beverage: Ensures hygiene and precision in filtering food products, such as fruit juices and dairy solutions.

- Water Treatment: Provides reliable filtration for wastewater and drinking water purification systems.

- Pharmaceuticals: Maintains strict purity standards in the filtration of medicinal compounds and solvents.

Our wedge wire screen is also widely used in wedge wire filter screen applications for industrial air and gas filtration, offering consistent performance in high-volume operations.

Why Choose Muto Wire Screen Co., Ltd.?

With over a decade of experience in the wire mesh industry, Muto Wire Screen Co., Ltd. has established itself as a trusted provider of wedge wire screen solutions. Our commitment to quality and innovation is reflected in:

- Advanced Manufacturing Technology: State-of-the-art machinery ensures precise production of wedge wire mesh with tight tolerances.

- Comprehensive R&D Capabilities: Our team continuously develops new solutions to address evolving industry needs.

- Global Market Expertise: We supply wedge wire screen to clients in over 50 countries, adapting to diverse operational requirements.

- Customization Services: Tailored solutions for unique applications, including special coatings and configurations.

Visit our company page to learn more about our production capabilities and certifications.

Customer Success Stories

Our wedge wire screen has been widely adopted by industries seeking reliable filtration solutions. For example:

Case Study 1: A leading mining company in Australia reduced maintenance costs by 40% after implementing our wedge wire filter screen in their ore classification system. Case Study 2: A food processing plant in Germany improved product quality and throughput by 30% using our wedge wire mesh for liquid filtration.

For more testimonials, explore our customer success stories.

Implementation and Maintenance Guide

To ensure optimal performance of your wedge wire screen, follow these guidelines:

- Installation: Ensure proper alignment with the filtration system to prevent leaks or misalignment.

- Operation: Monitor flow rates and pressure drops regularly to detect potential issues.

- Maintenance: Clean the screen periodically using non-abrasive materials to maintain efficiency.

- Inspection: Replace damaged sections promptly to avoid system downtime.

For detailed installation instructions, refer to our product documentation.

Environmental and Safety Compliance

All wedge wire screen products from Muto Wire Screen Co., Ltd. meet international safety and environmental standards. Our wedge wire mesh is manufactured using eco-friendly processes and is compliant with ISO 9001 and RoHS regulations. This ensures that our solutions are not only effective but also safe for operators and the environment.

Custom Solutions for Unique Needs

We understand that every industry has distinct requirements. Our team offers:

- Custom Dimensions: Tailor the size and shape of the wedge wire screen to fit your equipment.

- Material Options: Choose from stainless steel, carbon steel, or specialized alloys based on your application.

- Surface Treatments: Apply coatings such as Teflon or epoxy to enhance corrosion resistance.

Contact us today to discuss your specific needs and receive a personalized custom quote.

FAQs About Wedge Wire Screen

Q1: What is the maximum operating temperature for the wedge wire screen?

A: Our wedge wire filter screen can withstand temperatures up to 500°C, depending on the material used.

Q2: Can the wedge wire screen be used for high-pressure applications?

A: Yes, the robust design of the wedge wire mesh allows it to handle pressures up to 10 bar without deformation.

Q3: How long does the wedge wire screen last in corrosive environments?

A: With proper maintenance, our wedge wire screen can last over 10 years in environments with moderate corrosion.

Get in Touch

Ready to upgrade your filtration system with high-performance wedge wire screen? Contact Muto Wire Screen Co., Ltd. today for a free consultation and quotation. Our team is committed to providing tailored solutions that meet your operational goals.

Phone: +86-312-598-8888 Email: sales@mutoscreen.com Website: www.mutoscreen.com

Don't miss the opportunity to enhance your industrial processes with our wedge wire screen. Explore our product catalog and discover the perfect solution for your needs.