Wedge Wire Screen - Muto Wire Screen Co., Ltd.|High-Efficiency Filtration, Industrial Applications

Wedge Wire Screen: High-Efficiency Filtration Solution for Industrial Applications

Discover the advanced wedge wire screen technology from Muto Wire Screen Co., Ltd., a leading manufacturer of precision wire mesh solutions. Our wedge wire filter screen combines innovative design with durable materials to deliver exceptional performance in demanding industrial environments.

Understanding Wedge Wire Screen Technology

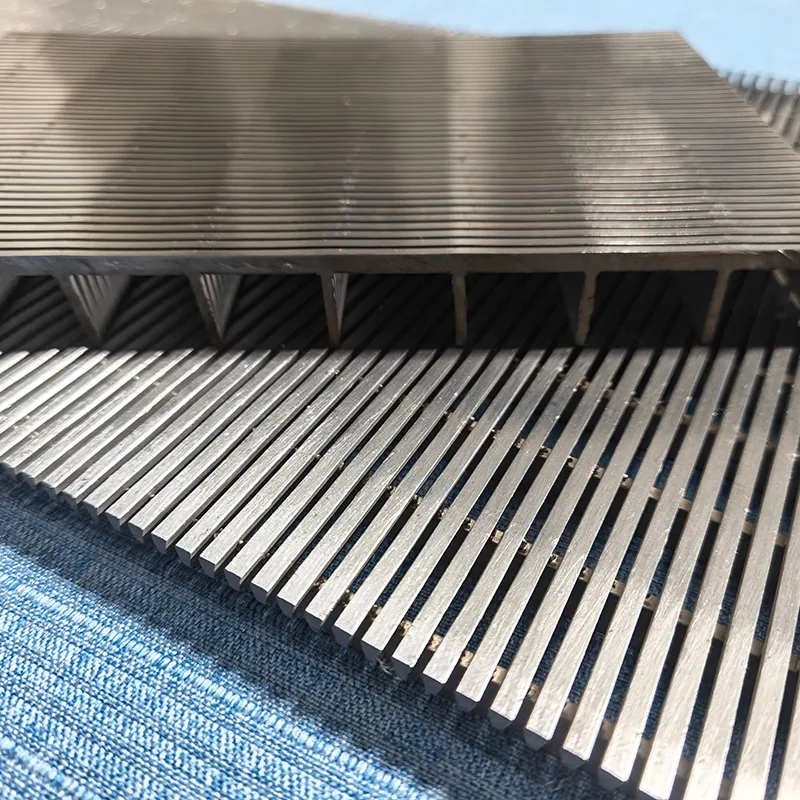

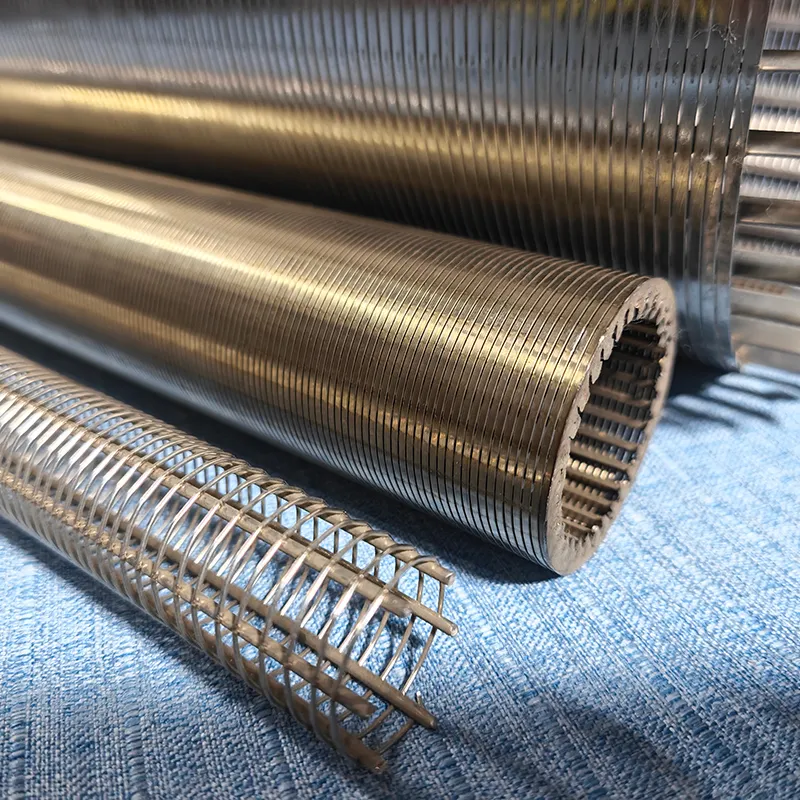

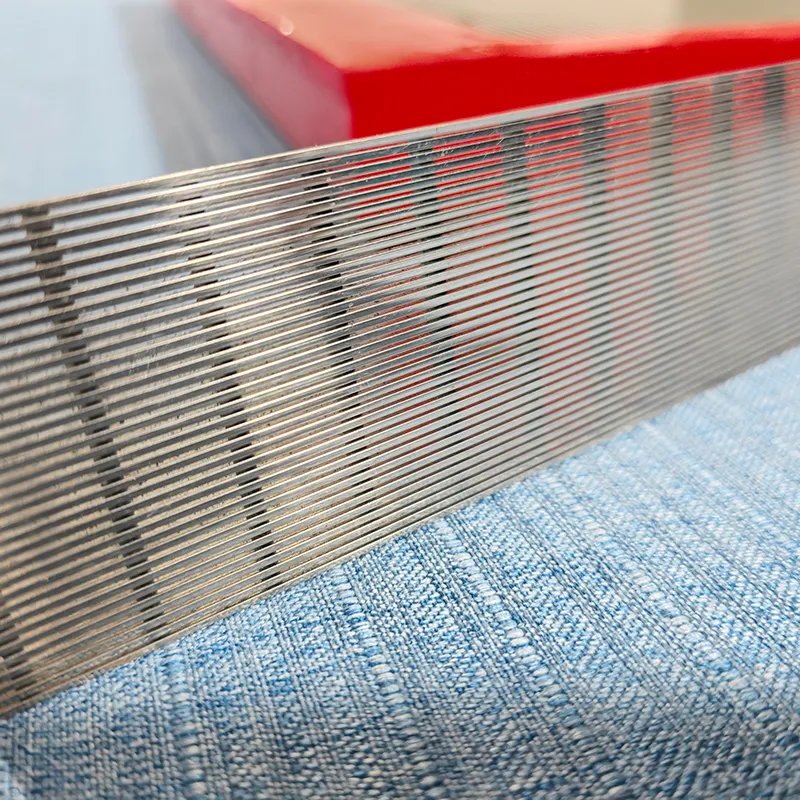

The wedge wire screen is a specialized type of wire mesh characterized by its unique cross-sectional shape. Unlike conventional square or round wire screens, the wedge wire design features a triangular cross-section that creates a more uniform flow pattern and enhanced filtration efficiency. This innovative design is particularly effective in applications requiring high throughput and precise particle separation.

Our wedge wire mesh is manufactured using high-quality carbon steel, stainless steel, or other specialized alloys, ensuring durability and resistance to corrosion. The precise engineering of the wedge wire geometry allows for consistent aperture sizes, making it ideal for applications where particle size control is critical.

Key Advantages of Wedge Wire Screens

- High Flow Capacity: The triangular cross-section reduces pressure drop while maintaining high flow rates

- Excellent Particle Retention: Uniform apertures ensure consistent separation performance

- Low Maintenance: Durable construction minimizes clogging and wear

- Customizable Designs: Available in various materials and configurations to suit specific application requirements

Industrial Applications of Wedge Wire Screens

Our sieve bend screen technology is widely used across multiple industries, including:

- Food and Beverage: For liquid filtration, pulp separation, and product clarification

- Pharmaceutical: In tablet coating processes and active ingredient filtration

- Chemical Processing: For efficient solid-liquid separation in reactors and storage tanks

- Water Treatment: As a primary filtration element in municipal and industrial water systems

- Mineral Processing: For dewatering and classification of fine particles

Addressing Industry Challenges with Advanced Technology

The industrial filtration market faces several persistent challenges, including:

- High maintenance costs due to frequent clogging and screen damage

- Inconsistent filtration performance from traditional mesh designs

- Limitations in handling high-viscosity or abrasive materials

- Environmental concerns related to filtration efficiency and material waste

Our wedge wire filter screen technology directly addresses these challenges through:

- Advanced wedge-shaped design that minimizes clogging and enhances flow efficiency

- Customizable configurations for specific material characteristics and application requirements

- Robust construction that withstands harsh operating conditions

- Environmentally friendly materials and manufacturing processes

Company Expertise and Technical Capabilities

Muto Wire Screen Co., Ltd., located in Anping County, has established itself as a leading manufacturer of precision wire mesh solutions. With over [X] years of experience in the industry, we have developed extensive technical expertise in:

- Wire mesh design and engineering

- Advanced manufacturing techniques

- Quality control and material testing

- Customized filtration solutions

Our state-of-the-art production facilities are equipped with the latest technology to ensure precision manufacturing and consistent quality. We maintain strict quality control standards throughout the production process, from raw material selection to final product inspection.

Proven Performance and Customer Testimonials

Our wedge wire screen solutions have been successfully implemented in numerous industrial applications, delivering measurable benefits to our clients. Some of our key performance achievements include:

- 20-30% increase in filtration efficiency for food processing clients

- 50% reduction in maintenance costs for chemical industry customers

- Improved product quality through precise particle separation in pharmaceutical applications

- Extended service life of filtration systems in mineral processing operations

Client feedback highlights the value of our solutions:

"The wedge wire screens from Muto Wire Screen have significantly improved our production efficiency. The consistent performance and low maintenance requirements have made a real difference in our operations." - [Client Name], Production Manager at [Company]

Implementation and Customization Options

We offer comprehensive support for integrating our wedge wire screen solutions into your existing systems. Our technical team can provide:

- Custom design services based on your specific application requirements

- Technical specifications and performance calculations

- Installation guidance and on-site support

- Regular maintenance and replacement services

For different applications, we recommend the following configurations:

- Food Processing: Stainless steel 304/316 for corrosion resistance

- Chemical Industry: Hastelloy or titanium for extreme environments

- Water Treatment: Carbon steel with epoxy coating for durability

Environmental and Safety Compliance

All our wedge wire filter screens meet international safety and environmental standards. We prioritize sustainable manufacturing practices and use materials that are safe for both operators and the environment. Our products are designed to:

- Minimize material waste through efficient filtration

- Reduce energy consumption with optimized flow design

- Comply with industry-specific safety regulations

Product Packaging and Shipping

We provide professional packaging solutions to ensure safe transportation of our wedge wire screen products. Our packaging includes:

- Custom wooden crates for large-scale orders

- Moisture-proof materials to protect against corrosion

- Clear labeling for easy identification and handling

For bulk orders, we offer competitive shipping solutions through our network of logistics partners. Our team can assist with all aspects of international and domestic transportation.

Comprehensive Customer Support

We are committed to providing exceptional customer service throughout the product lifecycle. Our support services include:

- 24/7 technical support

- On-site installation and training services

- Regular maintenance and performance optimization

- Custom product development and modification

Get in Touch with Muto Wire Screen Co., Ltd.

For more information about our wedge wire screen solutions, please contact us through the following channels:

- Contact Us Page

- Phone: +86 [Phone Number]

- Email: [Email Address]

- Address: [Company Address]

FAQs About Wedge Wire Screens

Q1: What materials are used in Muto's wedge wire screens?

A: We offer screens made from carbon steel, stainless steel (304, 316), and specialty alloys like Hastelloy and titanium, depending on the application requirements.

Q2: Can you customize wedge wire screens for specific applications?

A: Yes, our engineering team provides full customization services to design screens that match your unique process requirements.

Q3: What is the typical service life of a wedge wire screen?

A: With proper maintenance, our screens can last 3-5 years depending on the operating conditions and material type.

Q4: How do you ensure the quality of your products?

A: We implement strict quality control measures throughout the manufacturing process, including material testing, dimensional verification, and performance evaluation.

Conclusion

Muto Wire Screen Co., Ltd. offers high-performance wedge wire filter screen solutions that deliver exceptional value to industrial customers. Our products combine advanced engineering with durable materials to meet the most demanding filtration challenges. For more information, visit our wedge wire screen product page.