Wedge Wire Screen-Muto Wire Screen Co., Ltd.|High-Performance Metal Mesh&Industrial Filtration Solutions

Wedge Wire Screen: High-Performance Metal Mesh for Industrial Applications

As a leading manufacturer of metal wire mesh, Muto Wire Screen Co., Ltd. offers high-quality wedge wire screens designed to meet the demanding requirements of modern industrial applications. Our wedge wire screens are engineered for durability, precision, and efficiency, making them ideal for a wide range of filtration and screening processes. Discover how our products can enhance your production capabilities and deliver long-term value.

Understanding Wedge Wire Screens

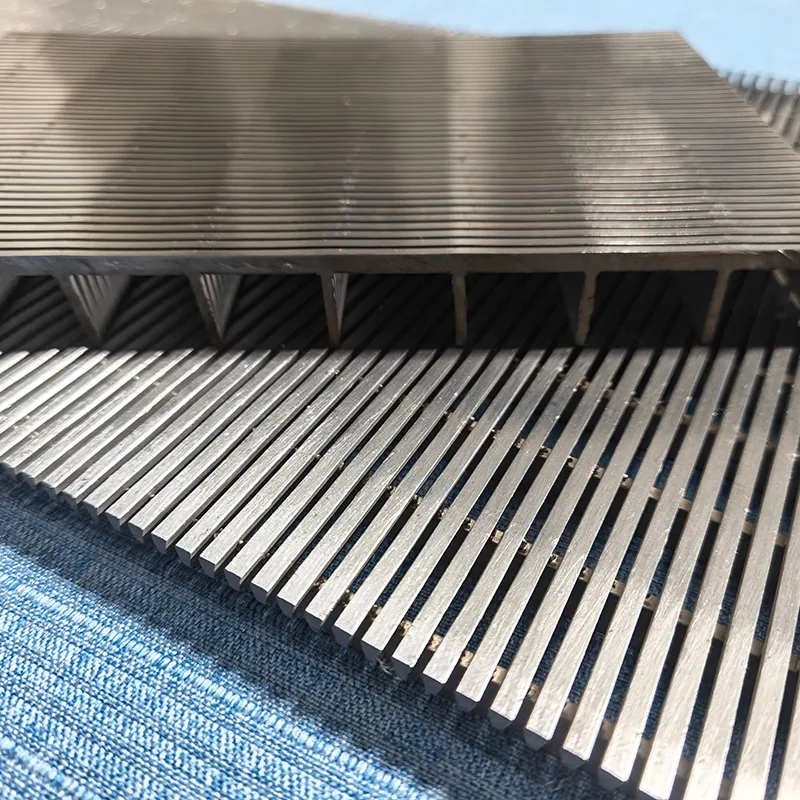

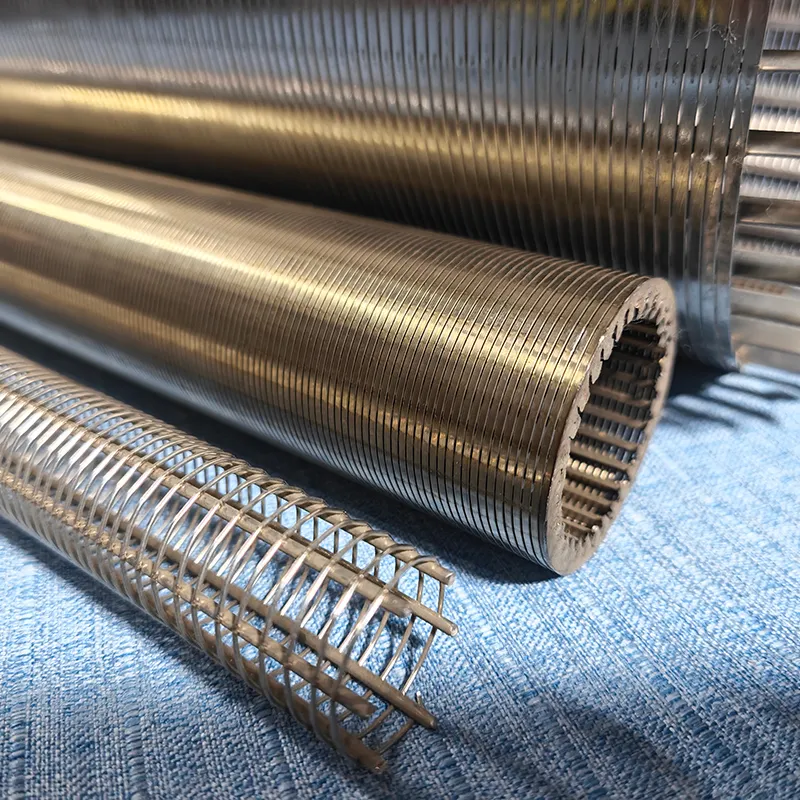

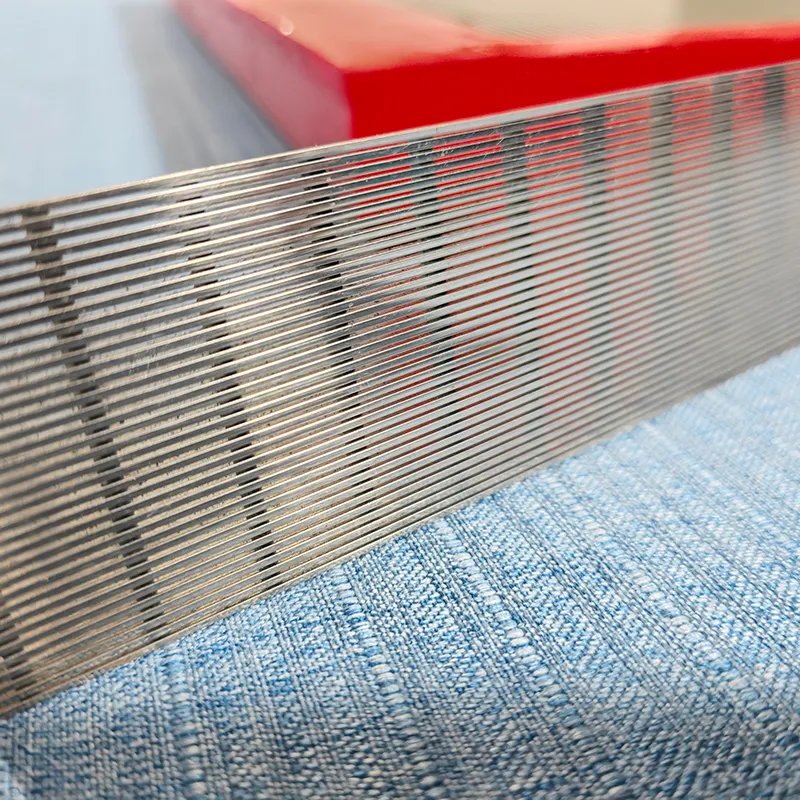

Wedge wire screens are a type of metal mesh characterized by their unique design, where metal wires are arranged in a wedge-shaped profile. This structure provides a high strength-to-weight ratio and excellent resistance to wear and tear. The precision engineering of wedge wire screens ensures consistent pore sizes, making them ideal for applications requiring high filtration efficiency and long service life.

Our wedge wire screens are manufactured using advanced techniques to ensure uniformity in wire spacing and thickness. This precision guarantees reliable performance in even the harshest industrial environments. Whether you're dealing with abrasive materials or high-pressure applications, our screens are designed to deliver consistent results.

Applications in Industrial Processes

Wedge wire screens find extensive use in industries such as mining, chemical processing, food and beverage, and pharmaceuticals. Their ability to handle high volumes of material while maintaining filtration accuracy makes them a preferred choice for various screening and separation tasks.

For example, in the mining industry, wedge wire screens are used to separate fine particles from larger aggregates. In the chemical sector, they ensure the purity of liquids by effectively removing impurities. In food processing, their hygienic design and corrosion resistance make them suitable for handling sensitive materials.

Addressing Industry Challenges

Traditional screening solutions often struggle with issues such as clogging, wear, and inconsistent performance. Muto Wire Screen Co., Ltd. addresses these challenges by developing wedge wire screens that are resistant to deformation and corrosion. Our products are designed to minimize maintenance requirements and reduce downtime, ensuring continuous operation for your business.

Additionally, our wedge wire screens offer enhanced flow rates compared to conventional screens. This is achieved through optimized wire spacing and a streamlined design that reduces pressure drop while maintaining high filtration efficiency. By choosing our products, you can improve your operational efficiency and reduce costs associated with frequent replacements.

Company Expertise and Innovation

With years of experience in the metal wire mesh industry, Muto Wire Screen Co., Ltd. has established itself as a trusted provider of high-quality screening solutions. Our commitment to innovation and quality control ensures that every wedge wire screen meets the highest standards of performance and reliability.

Our R&D team continuously invests in new technologies to enhance the capabilities of our products. This includes the use of advanced materials and precision manufacturing techniques to improve the durability and efficiency of our screens. By staying at the forefront of technological advancements, we ensure that our customers receive cutting-edge solutions tailored to their specific needs.

Proven Performance and Customer Feedback

Many clients have reported significant improvements in efficiency and cost savings after using our wedge wire screens. For instance, a leading mining company in Asia reported a 30% reduction in maintenance costs and a 20% increase in throughput after switching to our screens. Similarly, a food processing facility in Europe noted a marked improvement in product quality due to the consistent filtration performance of our products.

Our customers appreciate the reliability and longevity of our wedge wire screens, which contribute to their overall operational efficiency. By choosing Muto Wire Screen Co., Ltd., you're not just purchasing a product—you're investing in a partnership that values your success.

Usage Guidelines and Customization Options

To maximize the performance of our wedge wire screens, we recommend following the guidelines provided in our technical specifications. These include recommendations for installation, maintenance, and operational parameters based on the specific application requirements.

We also offer customization options to suit your unique needs. Whether you require a specific wire size, mesh pattern, or material composition, our team can work with you to develop a tailored solution. This flexibility ensures that our products can be adapted to a wide range of industrial applications.

Safety and Compliance

Safety is a top priority at Muto Wire Screen Co., Ltd. Our wedge wire screens are manufactured to meet international safety and environmental standards. They are free from hazardous substances and are designed to operate safely in various industrial environments.

Additionally, our products are certified to comply with relevant regulations, ensuring that you can use them with confidence. This commitment to safety and quality is a testament to our dedication to providing reliable and sustainable solutions for our customers.

Packaging and Delivery

Our wedge wire screens are packaged in sturdy, moisture-resistant containers to ensure they arrive in optimal condition. We offer flexible packaging options to accommodate bulk orders, making it easy for you to manage your inventory and logistics.

Our efficient shipping network ensures timely delivery to locations worldwide. We work closely with trusted logistics partners to provide reliable and cost-effective shipping solutions. For more information on our packaging and delivery options, visit our product page.

Comprehensive Support and After-Sales Service

We provide comprehensive support to ensure your satisfaction with our products. Our dedicated team is available to assist with technical inquiries, installation guidance, and product customization. We also offer training programs to help you get the most out of our wedge wire screens.

Our after-sales service includes regular maintenance checks and prompt assistance with any issues that may arise. This ensures that you can rely on our products for long-term performance and minimal downtime.

Contact Us for More Information

Ready to experience the benefits of our high-performance wedge wire screens? Contact Muto Wire Screen Co., Ltd. today to learn more about our products and how we can meet your specific needs. For detailed information about our wedge wire screens, visit our product page.

Phone: +86-123-456-7890 | Email: info@mutoscreen.com | Website: www.mutoscreen.com

Conclusion

Invest in high-quality wedge wire screens from Muto Wire Screen Co., Ltd. to enhance your industrial processes and achieve greater efficiency. Our products are designed to deliver reliable performance and long-term value, making them an essential component of your operations.

Frequently Asked Questions (FAQ)

What materials are used in the manufacturing of wedge wire screens?

Our wedge wire screens are made from high-quality stainless steel and other corrosion-resistant materials, ensuring durability and long service life.

Can the screens be customized for specific applications?

Yes, we offer customization options to meet the unique requirements of different industries and applications.

What is the typical delivery time for orders?

Delivery times vary depending on the order size and location. We work with trusted logistics partners to ensure timely and reliable delivery.

Are the screens safe for use in food and pharmaceutical industries?

Yes, our screens are manufactured to meet the hygiene and safety standards required for use in food and pharmaceutical applications.