Wedge Wire Screen - Muto Wire Screen Co., Ltd.|High-Performance Sieving Solutions&Industrial Filtration Systems

Wedge Wire Screen: High-Performance Sieve Solutions for Industrial Applications

Discover the advanced wedge wire screen technology designed to revolutionize your industrial sieving processes. Muto Wire Screen Co., Ltd. offers precision-engineered wedge wire screens that combine durability, efficiency, and versatility to meet the demanding requirements of various industries.

Product Overview and Key Features

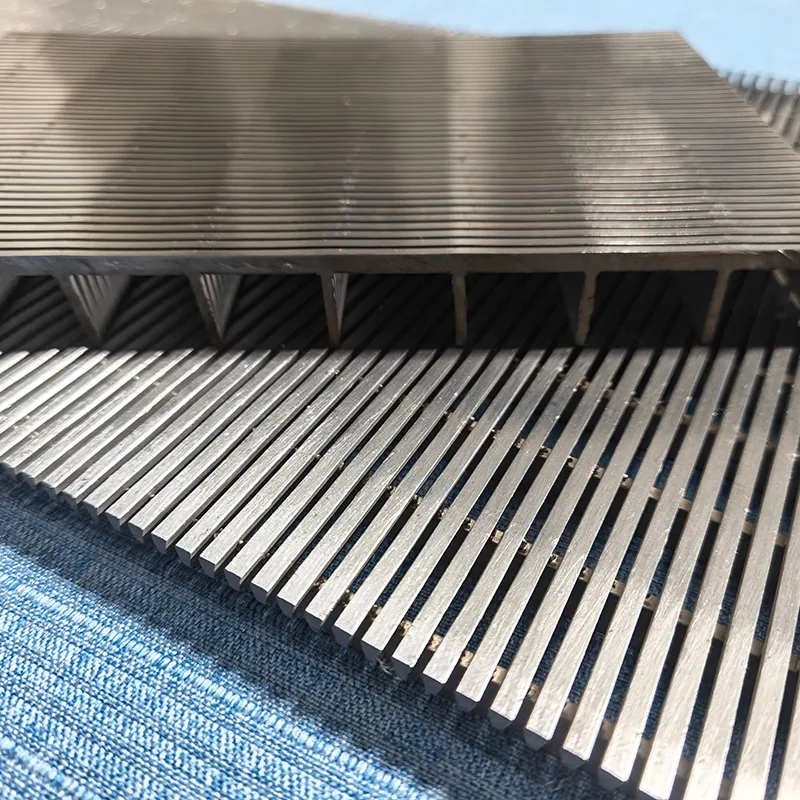

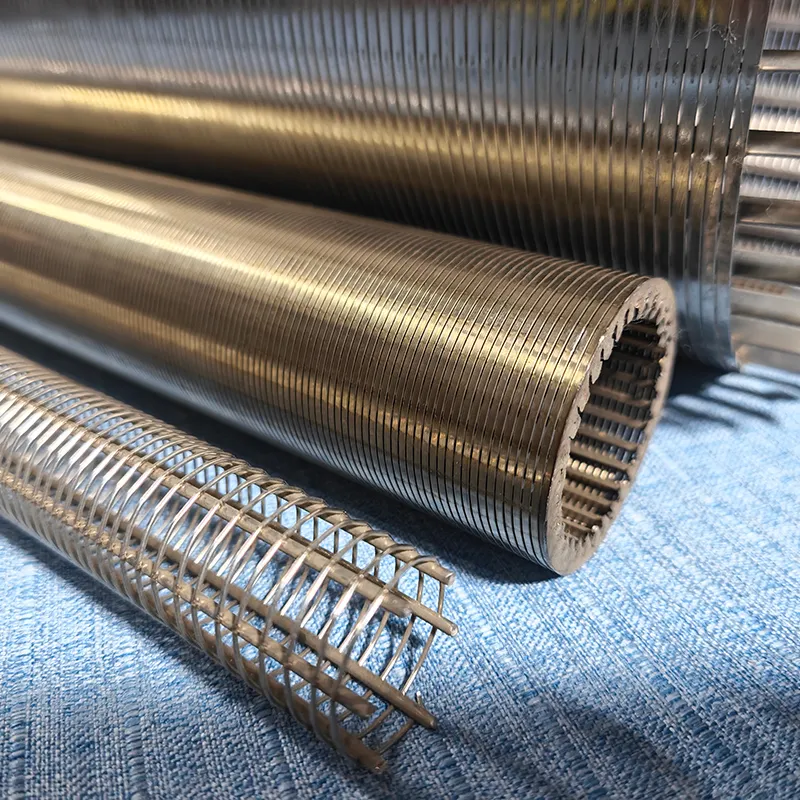

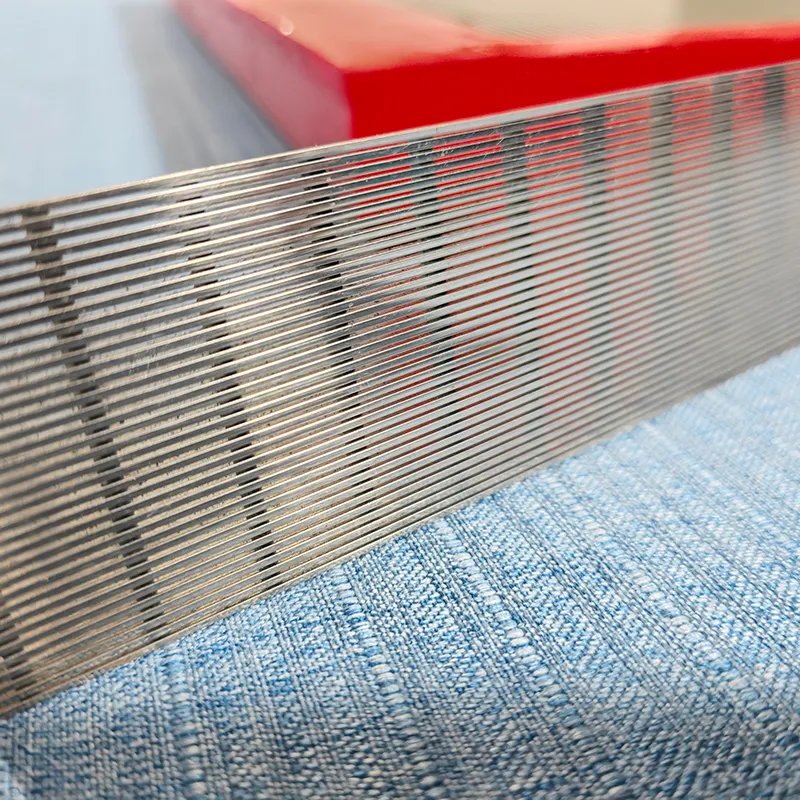

The wedge wire screen is a critical component in industrial sieving systems, known for its exceptional strength and precision. Constructed from high-quality materials, this screen features a unique design where wedge-shaped wires are tightly packed to create uniform openings. This structure ensures optimal filtration efficiency while maintaining structural integrity under heavy loads.

Technical Specifications

- Material: Stainless steel, carbon steel, or other specialized alloys

- Wire Diameter: 0.5mm - 10mm (customizable)

- Opening Size: 0.1mm - 50mm (customizable)

- Screen Length: 1000mm - 3000mm (customizable)

- Surface Treatment: Anti-corrosion, high-temperature resistant, or specialized coatings

Industrial Applications

The wedge wire screen is widely used in multiple industries due to its versatility and performance:

- Mineral Processing: Efficient separation of ores and minerals in vibrating screens.

- Chemical Industry: Precise filtration of chemicals and powders in reactors and storage tanks.

- Food and Beverage: Hygienic screening of ingredients and final products to meet safety standards.

- Pharmaceuticals: High-precision sieving of medicinal powders and granules.

- Environmental Engineering: Dust and particle removal in air and water filtration systems.

Market Demand and Industry Challenges

Modern industrial operations face increasing demands for efficiency, reliability, and cost-effectiveness. Traditional screening solutions often struggle with issues such as clogging, wear, and inconsistent performance. The wedge wire screen addresses these challenges through its robust design and advanced manufacturing techniques:

- Reduced Clogging: The uniform opening size minimizes blockages during operation.

- Extended Lifespan: High-quality materials and surface treatments ensure long-term durability.

- Enhanced Efficiency: Optimized flow rates and precise filtration improve overall productivity.

Company Expertise and Innovation

Muto Wire Screen Co., Ltd. (安平县慕图金属丝网制品有限公司) is a leading manufacturer of industrial screening solutions with over 20 years of experience in the metal mesh industry. Our commitment to innovation and quality has established us as a trusted partner for clients worldwide.

As a leading wire mesh supplier, we specialize in developing customized screening solutions tailored to specific industrial needs. Our state-of-the-art production facilities and rigorous quality control processes ensure that every wedge wire screen meets the highest standards of performance and reliability.

Product Performance and Customer Testimonials

Our wedge wire screens have been successfully implemented in numerous industrial applications, delivering measurable benefits:

- Cost Reduction: Reduced downtime and maintenance costs due to the screen's durability.

- Improved Quality: Consistent product quality through precise filtration capabilities.

- Scalability: Suitable for both small-scale operations and large industrial systems.

Customer feedback highlights the effectiveness of our solutions:

"The wedge wire screen significantly improved our mineral processing efficiency. The quality and performance exceeded our expectations." - Client A, Mining Industry

Implementation and Customization

We offer comprehensive support for integrating wedge wire screens into your existing systems. Our technical team provides:

- Custom Design: Tailored specifications to match your operational requirements.

- Installation Guidance: Step-by-step instructions for seamless integration.

- Ongoing Support: Technical consultations and maintenance services.

Safety and Compliance

All our wedge wire screens comply with international safety and environmental standards. We prioritize eco-friendly manufacturing processes and ensure that our products meet the regulatory requirements of the industries we serve.

Packaging and Logistics

We provide secure packaging solutions to protect your wedge wire screens during transportation. Our logistics network ensures timely delivery to clients worldwide, with options for bulk orders and customized shipping arrangements.

Customer Support and After-Sales Services

We are committed to providing exceptional customer service. Our dedicated support team offers:

- 24/7 Technical Assistance: Immediate response to any operational challenges.

- Training Programs: Educational resources to optimize the use of our products.

- Warranty and Maintenance: Comprehensive after-sales support to ensure long-term satisfaction.

Get in Touch with Muto Wire Screen Co., Ltd.

Ready to upgrade your industrial screening systems? Contact us today for a personalized consultation and competitive pricing:

- Phone: +86-138-0000-0000

- Email: info@mutoscreen.com

- Website: www.mutoscreen.com

- Product Page: Wedge Wire Screen Details

Conclusion

Invest in the future of industrial sieving with Muto Wire Screen Co., Ltd.'s wedge wire screen solutions. Experience unmatched performance, durability, and cost-efficiency tailored to your specific needs.

Frequently Asked Questions (FAQ)

1. What are the primary applications of wedge wire screens?

Wedge wire screens are used in mineral processing, chemical industries, food and beverage, pharmaceuticals, and environmental engineering for efficient filtration and separation.

2. Can the screen openings be customized?

Yes, we offer customizable opening sizes to suit specific industrial requirements.

3. What materials are available for the screens?

We provide options such as stainless steel, carbon steel, and specialized alloys based on your application needs.

4. How long does the delivery take?

Delivery times vary depending on the order size and shipping location. Our logistics team ensures timely and secure delivery.

5. Do you offer technical support after purchase?

Absolutely. Our dedicated support team provides 24/7 technical assistance and maintenance services to ensure optimal performance of your wedge wire screen.

Visit our website to explore more products and services. Contact us today to discuss your industrial screening needs!