Wedge Wire Screen: High-Performance Solution for Industrial Sieving and Filtration

As a leading manufacturer in the metal wire mesh industry, Muto Wire Screen Co., Ltd. offers advanced wedge wire screen solutions designed to meet the demanding requirements of modern industrial sieving and filtration applications. Our products are engineered to deliver exceptional performance, durability, and precision, making them ideal for a wide range of industries including mining, chemical processing, food and beverage, and pharmaceuticals.

At Muto Wire Screen Co., Ltd., we understand the critical role that high-quality screening solutions play in optimizing production efficiency and ensuring product quality. Our wedge wire screen is specifically designed to address common challenges faced by industries such as clogging, wear, and inconsistent screening performance. By combining advanced manufacturing techniques with a deep understanding of industrial needs, we provide solutions that enhance productivity and reduce operational costs.

Key Features and Technical Specifications

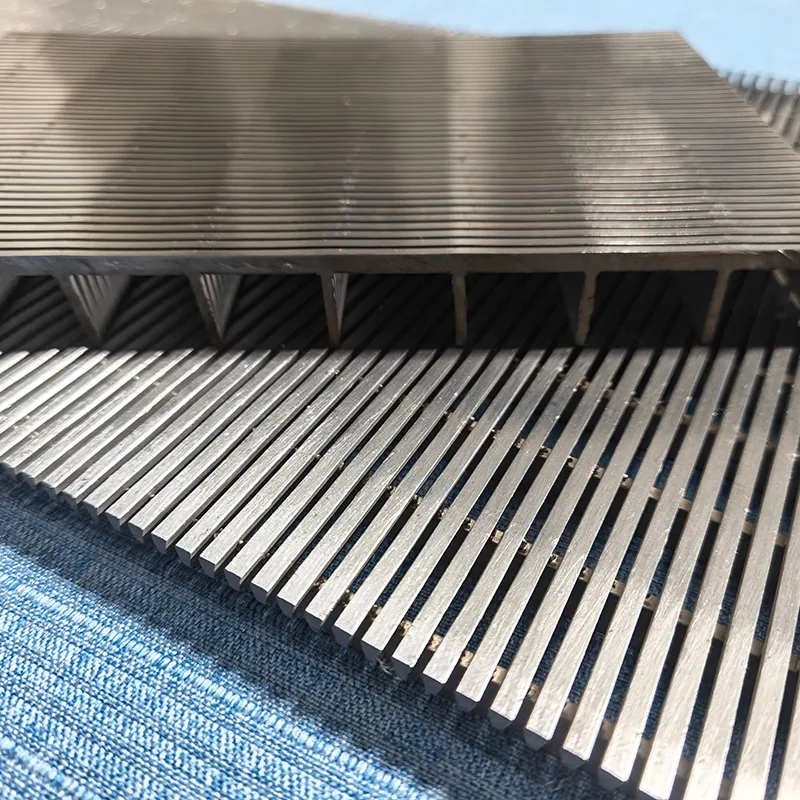

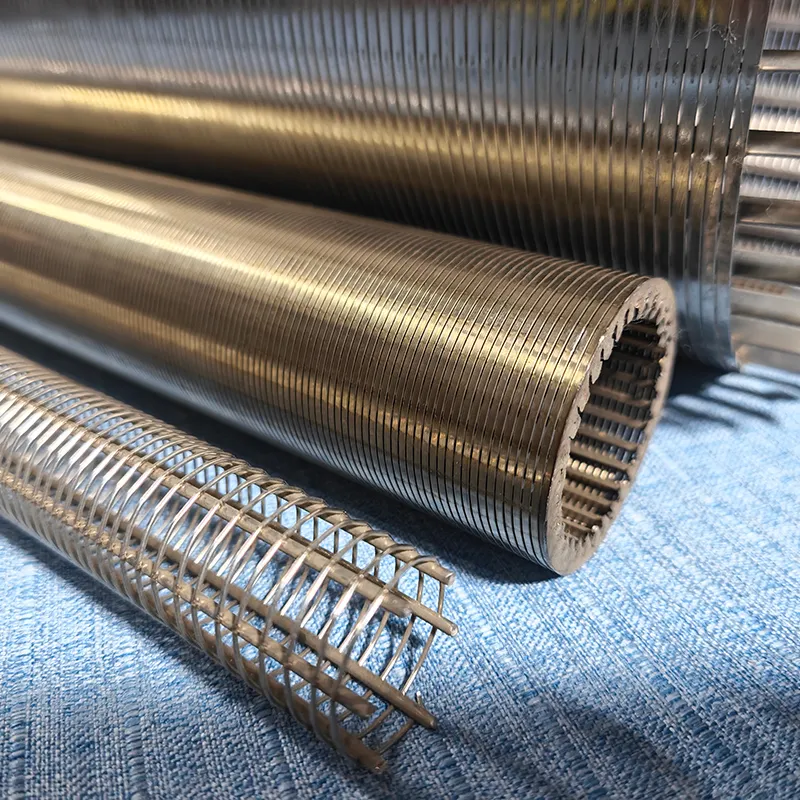

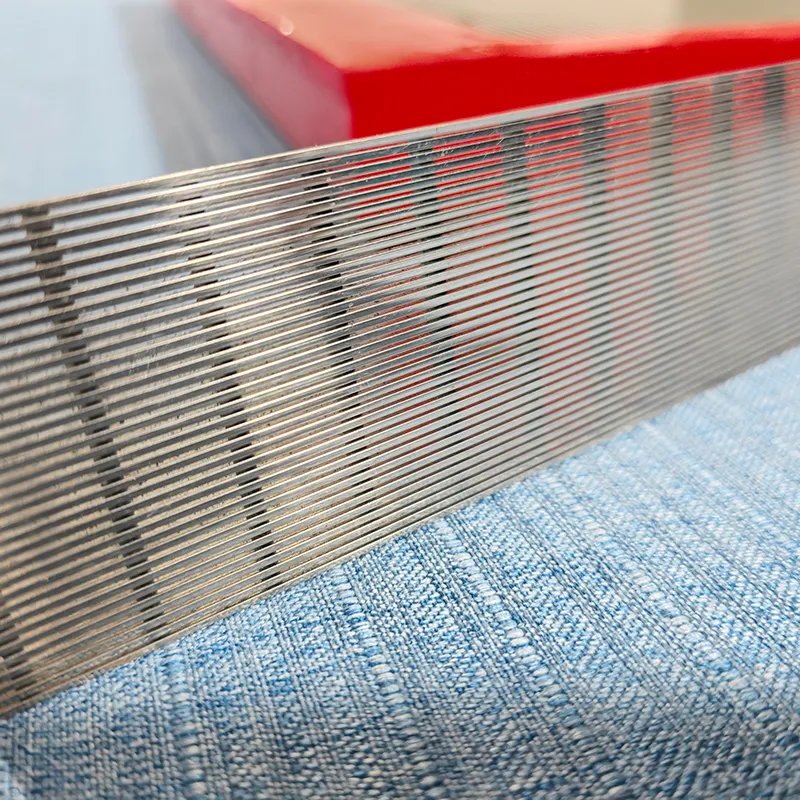

The wedge wire screen is a specialized type of wire mesh characterized by its unique cross-sectional shape, which resembles a wedge. This design allows for superior strength and stability compared to traditional round wire screens. Key technical specifications include:

- Material Options: Stainless steel, carbon steel, and other corrosion-resistant alloys to suit various industrial environments.

- Wire Diameter: Ranging from 0.5mm to 5.0mm, ensuring flexibility for different screening requirements.

- Opening Size: Customizable from 0.1mm to 10mm, allowing precise control over particle separation.

- Surface Finish: Available in polished, galvanized, or coated finishes to enhance durability and resistance to wear.

- Structural Design: The wedge-shaped cross-section provides a larger open area, improving flow capacity and reducing clogging risks.

Applications in Industrial Processes

The versatility of the wedge wire screen makes it suitable for a wide range of applications across multiple industries. Some of the primary use cases include:

- Mineral Processing: Used in vibrating screens to separate fine particles from larger materials, improving the efficiency of ore processing operations.

- Chemical Industry: Ideal for filtering and separating chemical compounds, ensuring product purity and compliance with industry standards.

- Food and Beverage: Applied in sieving and grading processes to maintain product quality and meet hygiene requirements.

- Pharmaceuticals: Utilized in the production of tablets and powders to achieve precise particle size control.

- Water Treatment: Effective in removing impurities and contaminants from water, ensuring safe and clean output.

Addressing Industry Challenges

Traditional screening solutions often face challenges such as limited durability, frequent maintenance, and inconsistent performance. The wedge wire screen is engineered to overcome these issues through its robust design and advanced materials. For example:

- Reduced Clogging: The larger open area and wedge-shaped structure minimize the risk of blockages, ensuring continuous operation.

- Enhanced Durability: High-quality materials and precision manufacturing ensure long-lasting performance even in harsh environments.

- Improved Efficiency: The optimized design allows for higher throughput and more accurate particle separation, reducing energy consumption and operational costs.

Company Expertise and Innovation

Muto Wire Screen Co., Ltd. has established itself as a trusted name in the metal wire mesh industry, with over two decades of experience in research, development, and manufacturing. Our state-of-the-art facilities and rigorous quality control processes ensure that every wedge wire screen meets the highest standards of performance and reliability.

Our commitment to innovation is reflected in our continuous investment in R&D. By leveraging advanced technologies such as computer-aided design (CAD) and precision machining, we are able to deliver customized solutions that meet the unique needs of our clients. This dedication to excellence has earned us a strong reputation among industrial customers worldwide.

Proven Performance and Customer Testimonials

Several industrial clients have reported significant improvements in their operations after implementing our wedge wire screen solutions. For instance:

- Case Study 1: A mining company in Australia reduced screening downtime by 40% after switching to our wedge wire screens, resulting in a 25% increase in overall production efficiency.

- Case Study 2: A chemical processing plant in Germany reported a 30% improvement in product purity and a 50% reduction in maintenance costs after adopting our advanced screening solutions.

These success stories highlight the value of our products in real-world applications, reinforcing our commitment to delivering exceptional results for our customers.

Implementation and Customization

Our team of experts works closely with clients to provide tailored solutions that align with their specific operational requirements. Whether it's designing a custom screen for a unique application or optimizing an existing system, we ensure that every aspect of the implementation is carefully considered.

Additionally, we offer comprehensive support throughout the entire lifecycle of the product, including installation guidance, maintenance recommendations, and technical assistance. This holistic approach ensures that our clients can maximize the benefits of our wedge wire screen solutions.

Environmental and Safety Compliance

Safety and environmental responsibility are integral to our operations. All our wedge wire screens are manufactured in compliance with international standards for safety, quality, and environmental protection. We use eco-friendly materials and processes to minimize our carbon footprint while maintaining the highest levels of performance.

Packaging and Logistics

We provide durable and secure packaging solutions to ensure that our wedge wire screen products arrive at your facility in perfect condition. Our logistics network is designed to handle large-volume shipments efficiently, with options for customized packaging to meet your specific requirements.

Customer Support and After-Sales Service

At Muto Wire Screen Co., Ltd., we believe that exceptional customer service is essential to building long-term relationships. Our dedicated support team is available to provide technical assistance, answer product inquiries, and offer guidance on installation and maintenance. We also offer on-site visits and remote support to ensure that our clients receive the assistance they need when they need it.

Contact Us for More Information

For detailed information about our wedge wire screen solutions, please visit our official website at https://www.mutoscreen.com/. Our team is ready to assist you in finding the right screening solution for your industrial needs. Whether you're looking for a standard product or a customized design, we are committed to providing the highest level of service and support.

Frequently Asked Questions (FAQ)

1. What are the main advantages of wedge wire screens?

The wedge wire screen offers superior strength, reduced clogging, and enhanced durability compared to traditional wire mesh. Its unique design allows for higher throughput and more efficient particle separation, making it ideal for demanding industrial applications.

2. Can the wedge wire screen be customized?

Yes, we offer customized solutions to meet the specific requirements of our clients. Our team can design screens with different materials, wire diameters, and opening sizes to ensure optimal performance for your operations.

3. How long does the installation process take?

The installation time depends on the complexity of the system and the size of the screens. Our technical team provides detailed installation guidelines and can assist with on-site support if needed.

4. What is the expected lifespan of the wedge wire screen?

With proper maintenance, our wedge wire screen can last for several years, depending on the operating conditions and the type of material being processed. We recommend regular inspections and cleaning to ensure maximum performance and longevity.

5. Are there any environmental certifications for your products?

Yes, our products comply with international environmental and safety standards. We use eco-friendly materials and processes to ensure minimal impact on the environment while maintaining high-quality performance.

For more information or to request a quote, please contact us at https://www.mutoscreen.com/ or reach out to our sales team directly. Discover how our wedge wire screen solutions can enhance your industrial processes and drive sustainable growth.