In the vast and intricate world of industrial processing, particularly within sectors like mining, aggregates, chemical engineering, and wastewater treatment, the efficiency and reliability of equipment are paramount. At the heart of many separation and classification processes lies the vibrating screen, a critical piece of machinery responsible for separating materials by size. However, the true unsung hero ensuring its longevity, performance, and the integrity of the screening media is often overlooked: the backing plate. This comprehensive guide delves into the essential role of the **what does a vibrating plate do for you** specifically focusing on the Vibrating Screen Backing Plate, its technical intricacies, manufacturing excellence, and its profound impact on your operational efficiency and bottom line.

Understanding the Core: What Does a Vibrating Plate Do For You?

When we ask "**what does a vibrating plate do for you**," in the context of industrial vibrating screens, we are fundamentally asking about the crucial function of the Vibrating Screen Backing Plate and its contribution to the overall screening process. A vibrating screen's primary purpose is to efficiently separate granular materials based on particle size. This is achieved by subjecting the material to intense, rapid vibrations, which agitate the particles, allowing smaller ones to pass through the screen media while larger ones are retained.

The Vibrating Screen Backing Plate serves as the foundational support structure for the actual screening media – often polyurethane screens, woven wire mesh, or rubber panels. Without a robust and precisely engineered backing plate, the delicate screen media would quickly succumb to the immense dynamic forces and abrasive wear inherent in the screening process. Therefore, the backing plate primarily performs several critical functions that directly benefit your operations:

- Structural Support and Integrity: It provides a rigid, flat, and stable base that evenly distributes the load of the material being screened, preventing the screen media from sagging, deforming, or tearing under stress. This ensures consistent and accurate screening performance.

- Vibration Transmission Optimization: The backing plate is engineered to efficiently transmit the vibrational energy from the screen's exciters directly to the screen media. This uniform energy transfer is vital for optimal material stratification and separation, maximizing screening efficiency and throughput.

- Prolonging Screen Media Lifespan: By offering a firm and consistent support, the backing plate significantly reduces localized stress points and premature wear on the screen media, such as pu screen panel. This extends the service life of expensive screen panels, leading to substantial cost savings on replacements and reduced downtime.

- Protection of Underlying Structure: It acts as a sacrificial layer, protecting the main vibrating screen frame from direct impact and abrasive wear caused by the material flow and the screen media itself.

- Facilitating Quick and Secure Installation: Designed with precise bolt patterns and mounting points, the backing plate ensures that screen media can be installed securely and efficiently, contributing to faster maintenance cycles.

In essence, the **vibrating screen backing plate** is not just a piece of metal; it is a meticulously designed component that ensures the entire screening system operates at peak performance, offering durability, efficiency, and cost-effectiveness "for you" as an operator or business owner.

Industry Trends and Technological Advancements

The industrial screening sector is constantly evolving, driven by demands for higher efficiency, lower operational costs, and enhanced sustainability. Several key trends directly impact the design and application of Vibrating Screen Backing Plates:

- Advanced Materials Science: There's a growing adoption of specialized high-strength steels and wear-resistant alloys that offer superior longevity and performance under extreme conditions, reducing the frequency of replacements.

- Precision Manufacturing: The rise of advanced CNC machining and robotic welding ensures tighter tolerances and higher accuracy in backing plate production, leading to better fit, improved vibration transfer, and extended component life.

- Digitalization and IoT Integration: While less direct for the plate itself, the broader trend of smart screening systems means backing plates must be designed for seamless integration, often featuring precise mounting points for sensors monitoring vibration, temperature, and wear.

- Sustainability Focus: Manufacturers are increasingly using recyclable materials and optimizing designs to reduce material waste during production and extend product lifespan, aligning with global environmental goals.

- Modular Design Concepts: A shift towards modular and easily replaceable components, including backing plates, to simplify maintenance and minimize downtime.

Technical Deep Dive: The Anatomy of a Vibrating Screen Backing Plate

The efficacy of a Vibrating Screen Backing Plate hinges on its material composition, precise dimensions, and structural integrity. MutoScreen's Vibrating Screen Backing Plates are engineered to meet the most stringent industry demands.

Key Technical Parameters and Material Considerations

The selection of material is paramount for a backing plate's performance. Common materials include high-strength low-alloy (HSLA) steels like Q235, Q345, or equivalents (e.g., ASTM A36, A572 Grade 50) for general applications. For highly abrasive or corrosive environments, specialized wear-resistant steels (e.g., Hardox, NM series) or stainless steels (e.g., 304, 316) might be employed. The choice depends heavily on the specific application, considering factors like:

- Tensile Strength: Ability to withstand pulling forces without breaking.

- Yield Strength: Resistance to permanent deformation.

- Hardness: Resistance to indentation and abrasion.

- Impact Toughness: Ability to absorb energy and deform plastically without fracturing.

- Corrosion Resistance: Crucial for wet or chemical environments.

- Fatigue Resistance: Ability to withstand repeated stress cycles from vibration.

Beyond material, critical geometric parameters include:

- Thickness: Typically ranges from 6mm to 20mm, determined by screen size, material load, and desired rigidity. Thicker plates offer greater strength but add weight.

- Flatness Tolerance: Essential for uniform support of the screen media and consistent vibration transfer. Deviations can lead to uneven wear.

- Hole Patterns and Sizes: Precisely machined to match specific screen media fastening systems (e.g., bolt-down, pin-and-sleeve, side-tensioned). Accuracy here is critical for secure installation and preventing media slippage.

- Surface Finish: Can be shot-blasted, painted, or coated for enhanced corrosion resistance or reduced friction.

- Weight: Optimized to provide necessary strength without unduly increasing the vibrating mass, which could impact energy consumption.

Vibrating Screen Backing Plate Key Specifications Table

| Parameter | Typical Range / Value | Importance for Performance |

|---|---|---|

| Material Type | High-Strength Steel (Q235, Q345, S235JR, S355JR), Wear-Resistant Alloys | Determines strength, hardness, fatigue & corrosion resistance. Crucial for longevity. |

| Plate Thickness | 6mm - 20mm (0.24" - 0.79") | Structural integrity, load distribution, rigidity. Prevents sagging. |

| Flatness Tolerance | Typically < 2mm over 1m length (0.08" over 3.28 ft) | Ensures even screen media support & uniform vibration transmission. Minimizes localized wear. |

| Hole Pattern Accuracy | ±0.5mm (±0.02") for bolt centers | Facilitates secure and quick installation of screen media. Prevents media displacement. |

| Surface Hardness | 120-200 HB (for standard steel); 400-600 HB (for wear-resistant steel) | Resistance to abrasive wear from materials. |

| Welding Standard | ISO 3834 / AWS D1.1 (if applicable for assembled plates) | Ensures structural integrity of welded joints under dynamic loads. |

| Corrosion Resistance | Varies by material (e.g., Stainless Steel for high resistance) | Prevents material degradation in wet or chemical environments, extending life. |

| Fatigue Strength | High (Designed for millions of cycles) | Ability to withstand continuous vibration without cracking or failure. |

Manufacturing Excellence: The Journey of a Vibrating Screen Backing Plate

The quality of a Vibrating Screen Backing Plate is directly proportional to the precision and rigor of its manufacturing process. MutoScreen adheres to a meticulous multi-stage production protocol to ensure every plate meets the highest standards. This process, which directly answers how a what does a vibrating plate do for you component comes to life, combines advanced technology with stringent quality control.

Detailed Manufacturing Process Flow:

-

Material Selection and Incoming Quality Control (IQC)

The journey begins with the careful selection of raw materials, typically high-grade steel sheets or plates. MutoScreen sources from reputable mills, ensuring materials meet specific chemical compositions and mechanical properties (e.g., yield strength, tensile strength, impact toughness). Upon arrival, each batch undergoes rigorous Incoming Quality Control (IQC) checks. This involves:

- Chemical Analysis: Spectrographic analysis to confirm alloy composition.

- Mechanical Testing: Tensile, impact, and hardness tests to verify strength and durability.

- Dimensional Inspection: Checking plate thickness and overall dimensions against specifications.

- Surface Inspection: Visual checks for defects, laminations, or inclusions.

Standard Reference: Adherence to international material standards like ASTM, EN, or JIS.

-

Precision Cutting and Profiling

Once material quality is assured, the large steel sheets are cut into the precise shapes required for the backing plates. This critical step employs advanced cutting technologies to achieve high accuracy and minimal material waste:

- CNC Laser Cutting: Ideal for intricate shapes and thin to medium thickness plates, offering extremely high precision and a clean edge finish.

- CNC Plasma Cutting: Faster and more cost-effective for thicker plates, providing good accuracy for larger profiles.

- High-Definition Waterjet Cutting: Used for sensitive materials or when heat-affected zones are to be avoided, offering exceptional precision.

This stage defines the outer dimensions and initial profile of the plate.

-

Forming and Bending (If Applicable)

Depending on the design, some backing plates may require bending or forming to create specific angles, flanges, or contours. This is performed using:

- CNC Press Brakes: For precise angle bending and complex shapes, ensuring consistent radii and dimensions.

- Plate Rolling Machines: For creating cylindrical or curved sections if the design calls for it.

Controlling springback and material deformation is crucial here to maintain dimensional accuracy.

-

Hole Punching/Drilling and Machining

This is arguably the most critical step for the backing plate's functionality. The precise placement and size of holes are essential for securely mounting the polyurethane screens or other screen media. This involves:

- CNC Punching Machines: For rapid and accurate creation of numerous holes in thinner plates.

- CNC Drilling Machines: For larger diameter holes or thicker plates where punching is not feasible.

- CNC Machining (Milling): Used for creating countersinks, precise slots, or complex mounting features that require tight tolerances. This may involve sophisticated CNC machining centers to ensure flatness and intricate details.

Inspection Point: After this stage, a detailed dimensional inspection of all hole positions, diameters, and flatness is conducted using CMM (Coordinate Measuring Machine) or optical measuring systems to ensure compliance with engineering drawings (e.g., ANSI B4.1 for hole tolerances).

-

Welding and Assembly (If Multi-Component)

For larger or more complex backing plates that consist of multiple fabricated sections, welding is performed. MutoScreen employs skilled and certified welders utilizing advanced techniques such as MIG (Gas Metal Arc Welding), TIG (Gas Tungsten Arc Welding), or Submerged Arc Welding (SAW) to ensure strong, durable, and defect-free joints. Robotic welding may be used for high-volume, repetitive tasks, ensuring consistency.

- Pre-heating and Post-weld Heat Treatment: May be applied to reduce residual stresses and improve weld integrity, especially for high-strength steels.

Standard Reference: Welding procedures conform to international standards like ISO 3834 and AWS D1.1.

-

Stress Relieving (Heat Treatment)

To mitigate internal stresses introduced during cutting, forming, and welding, and to enhance dimensional stability, backing plates may undergo stress relieving heat treatment. This process involves heating the plate to a specific temperature below its critical point, holding it for a period, and then slowly cooling it. This significantly improves the plate's long-term durability and resistance to deformation under dynamic loads.

-

Surface Preparation and Coating

The final step involves preparing the surface for protection and durability:

- Shot Blasting: Removes scale, rust, and prepares the surface for optimal paint adhesion, enhancing corrosion resistance.

- Painting/Coating: Application of high-performance industrial paints (e.g., epoxy, polyurethane coatings) or specialized anti-corrosion treatments to protect the plate from environmental factors and extend its lifespan.

-

Final Inspection and Quality Assurance (QA)

Every Vibrating Screen Backing Plate undergoes a comprehensive final inspection before dispatch. This ensures the finished product meets all specified requirements:

- Dimensional Verification: Using precision measuring tools (calipers, micrometers, laser trackers) to confirm all dimensions, hole locations, and flatness are within specified tolerances.

- Visual Inspection: Checking for surface defects, proper coating application, and overall aesthetic quality.

- Material Traceability: Ensuring all documentation (material certificates, test reports) is in order, allowing for complete traceability back to the raw material batch.

- Functional Checks: For complex plates, a fitment test with sample screen media may be performed.

Standard Reference: Overall quality management follows ISO 9001:2015 principles, ensuring a robust quality system throughout the production chain.

-

Packaging and Logistics

Plates are carefully packaged to prevent damage during transit, often using wooden crates, steel skids, or specialized protective wrapping, ensuring they arrive at the client's site in pristine condition.

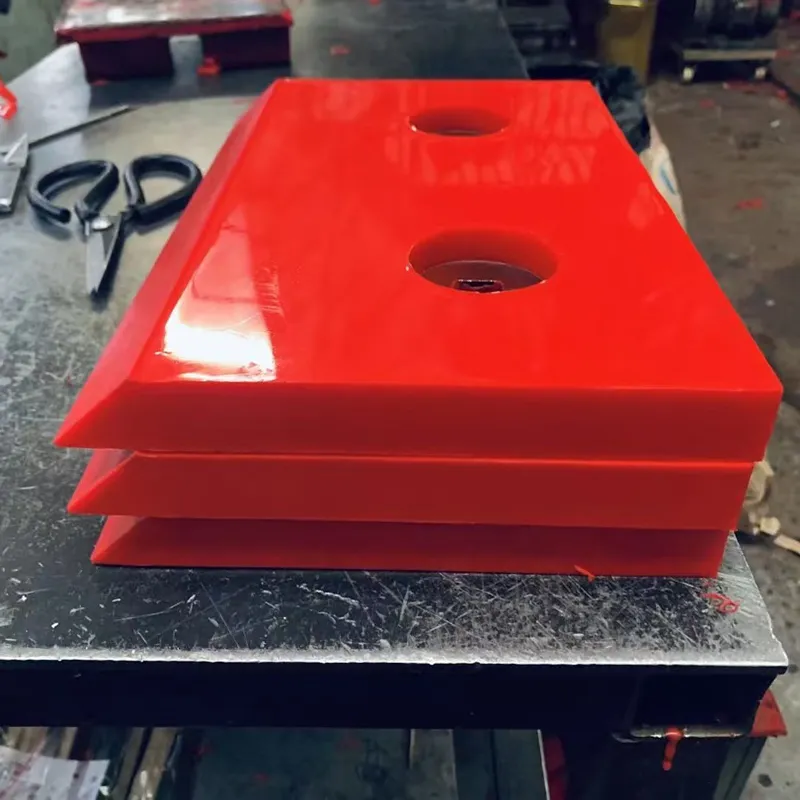

Fig 1: Precision machining ensures critical hole patterns for optimal screen media fitment.

This rigorous process ensures that each Vibrating Screen Backing Plate from MutoScreen is not just a component, but a highly engineered solution designed for maximum durability, reliability, and performance in the most demanding industrial applications. The emphasis on quality control at every stage, from material selection to final inspection, directly contributes to the exceptional service life and efficiency our clients experience.

Application Scenarios & Technical Advantages

The versatility and robust nature of the Vibrating Screen Backing Plate make it indispensable across a wide spectrum of industries. Its technical advantages directly translate into significant operational benefits for your business.

Applicable Industries:

- Mining and Quarrying: Essential for processing various ores (iron, gold, copper), coal, gravel, sand, and crushed stone. Backing plates here must withstand extreme abrasion, high impact loads, and continuous vibration.

- Aggregates Production: Used in the production of sand, gravel, and crushed stone for construction, requiring high wear resistance and consistent performance.

- Metallurgy and Steel Mills: Involved in sizing and separating raw materials like iron ore, coke, and slag, often in high-temperature environments.

- Chemical Processing: For screening powders, granules, and slurries in environments that may involve corrosive chemicals, requiring specialized material selection for corrosion resistance.

- Wastewater Treatment and Environmental Protection: Used for solid-liquid separation, dewatering, and grit removal. Backing plates here benefit from anti-corrosive properties and precise aperture for fine screening media like pu screen panel.

- Coal Preparation: For screening raw coal, separating different size fractions, and dewatering, where extreme wear resistance is crucial.

- Food and Pharmaceutical Industry: While less common for heavy-duty backing plates, specialized versions with high-grade stainless steel can be used for sanitary screening applications.

Product Advantages & Benefits:

The direct impact of a high-quality Vibrating Screen Backing Plate on your operations is multifaceted:

- Enhanced Screen Media Lifespan: By providing uniform and rigid support, the backing plate prevents premature wear, sagging, and tearing of screen media (e.g., polyurethane screens, wire mesh). This can extend the life of your screen panels by 20-50% or more, depending on the application and material quality.

- Reduced Downtime and Maintenance Costs: Longer screen media life directly translates to fewer change-outs, significantly reducing machine downtime for maintenance. This boosts overall productivity and lowers labor costs.

- Improved Screening Efficiency: A perfectly flat and stable backing plate ensures optimal vibration transfer and consistent material flow, leading to more accurate separation and higher throughput. This means more usable product and less waste.

- Energy Efficiency: By optimizing vibration transfer and supporting the screening process, a well-designed backing plate contributes to the overall efficiency of the vibrating screen, potentially reducing the energy consumed per ton of material processed.

- Superior Corrosion and Abrasion Resistance: Through careful material selection and surface treatments, MutoScreen's plates resist harsh operating conditions, ensuring longevity even in aggressive environments.

- Increased Safety: A stable and secure backing plate reduces the risk of screen media failure during operation, contributing to a safer working environment.

- Cost Savings: The combined benefits of extended screen media life, reduced downtime, and improved efficiency result in significant long-term operational cost savings. This is a direct answer to what does a vibrating plate do for you - it saves you money and boosts productivity.

Case Study Snippet: Mining Sector Productivity Boost

A major iron ore mining operation in Australia faced persistent issues with premature wear of their polyurethane screens, leading to frequent downtime. After integrating MutoScreen's custom-designed Vibrating Screen Backing Plates, manufactured from wear-resistant alloy steel with enhanced flatness tolerances, the client reported an average 35% increase in screen media lifespan and a 15% reduction in unplanned maintenance hours over a 12-month period. This tangible improvement directly resulted in higher ore processing volumes and substantial cost savings.

Comparative Analysis: Choosing the Right Backing Plate Supplier

Selecting the right supplier for Vibrating Screen Backing Plates is as crucial as the product itself. The market offers various manufacturers, but not all are created equal. MutoScreen distinguishes itself through a commitment to quality, engineering prowess, and comprehensive customer support.

Supplier Comparison Table

| Feature/Criteria | MutoScreen | Competitor A (Mass Market) | Competitor B (Niche OEM) |

|---|---|---|---|

| Quality Control & Standards | ISO 9001:2015 Certified. Rigorous IQC, IPQC, FQC. Material certifications & traceability. | Basic QC, inconsistent material certifications. | Good QC, often tied to specific OEM equipment. |

| Manufacturing Process | Advanced CNC Laser/Plasma, Precision Drilling/Milling, Robotic Welding, Stress Relieving. | Standard punching/flame cutting, manual welding. | High-precision, but limited to own designs. |

| Material Customization | Extensive, based on application (HSLA, wear-resistant, SS). Engineering consultation available. | Limited, standard steel only. | Varies, often proprietary alloys. |

| Design & Engineering Support | Full custom design, reverse engineering, optimization services. CAD/CAM integration. | Limited to standard designs, little engineering support. | Strong for their own equipment, less for general applications. |

| Delivery Lead Time | Optimized for efficiency, flexible for urgent orders. Standard 3-6 weeks, express options. | Can be long and inconsistent. | Often long, as parts are made to order for specific machine models. |

| After-Sales Support & Warranty | Comprehensive 12-24 month warranty, technical support, installation guidance. | Basic warranty, limited support. | Strong for their own machines, potentially limited for standalone parts. |

| Certifications & Accreditations | ISO 9001, Material Test Reports, Compliance to ASTM/EN/ANSI standards. | Often none beyond basic product specs. | May have internal OEM certifications. |

| Cost-Effectiveness (Long Term) | Higher initial investment, but significant long-term savings through extended life & efficiency. | Lower initial cost, but high long-term costs due to frequent replacements & downtime. | High initial cost, good performance for specific setups. |

MutoScreen's commitment to continuous improvement, adherence to global manufacturing standards, and focus on delivering genuine value to our clients positions us as a leader in providing high-performance Vibrating Screen Backing Plates. Our solutions are not just products; they are investments that enhance your operational longevity and profitability.

Customized Solutions: Tailoring to Your Specific Needs

Every industrial operation presents unique challenges, and a one-size-fits-all approach rarely yields optimal results. MutoScreen excels in providing highly customized Vibrating Screen Backing Plates that precisely match your equipment and operational demands. This bespoke approach ensures that the answer to **what does a vibrating plate do for you** is always "exactly what you need."

Our engineering team works closely with clients through a collaborative process:

- Detailed Consultation: Understanding your specific vibrating screen model, material characteristics, operating environment (temperature, humidity, corrosivity), existing challenges (premature wear, vibration issues), and desired outcomes.

- On-Site Assessment (If Feasible): For complex scenarios, our engineers can conduct on-site evaluations to gather critical data and observe operational dynamics.

- Design and Engineering: Utilizing advanced CAD/CAM software, we design a backing plate tailored to your exact specifications, optimizing for material type, thickness, hole patterns, mounting configurations, and surface treatments. We can reverse-engineer existing plates or design completely new solutions.

- Material Recommendation: Based on the application, we recommend the most suitable steel alloy or composite material to ensure maximum wear resistance, corrosion protection, and structural integrity. For example, for highly abrasive applications, Hardox or equivalent wear-resistant steels would be recommended. For marine or chemical environments, specific grades of stainless steel might be chosen.

- Prototype and Testing (Optional): For novel designs or critical applications, we can produce prototypes for client evaluation and testing before full-scale production.

- Manufacturing and Quality Assurance: The customized design then enters our stringent manufacturing process, with every stage meticulously monitored to ensure the final product matches the agreed-upon specifications.

This commitment to customization ensures that your Vibrating Screen Backing Plate is perfectly integrated into your system, maximizing efficiency and minimizing unforeseen issues.

Ensuring Trust and Reliability: MutoScreen's Commitment (EEAT - Trustworthiness)

Trust is the cornerstone of any successful partnership. At MutoScreen, we build trust through transparency, adherence to the highest quality standards, and unwavering customer support. Our commitment to excellence is embodied in our certifications, service philosophy, and comprehensive guarantees.

Quality Assurance and Certifications

MutoScreen's manufacturing processes are fully compliant with ISO 9001:2015 Quality Management System standards. This certification is not merely a formality; it reflects our deeply ingrained culture of continuous improvement, rigorous process control, and a customer-centric approach. Every Vibrating Screen Backing Plate undergoes:

- Multi-stage Inspection: From raw material receiving (IQC) through in-process checks (IPQC) to final product verification (FQC), ensuring compliance at every step.

- Material Traceability: Full traceability of materials from the steel mill to the final product, allowing for complete transparency and accountability.

- Performance Testing: While destructive testing on every plate is impractical, representative samples or material batches are subjected to mechanical tests (tensile, impact, hardness) to validate properties. Non-destructive testing (NDT) like ultrasonic or magnetic particle inspection may be applied to welds on critical components.

- Dimensional Accuracy Reports: Detailed inspection reports confirming critical dimensions, hole patterns, and flatness are available upon request.

Warranty and After-Sales Support

We stand behind the quality of our Vibrating Screen Backing Plates. MutoScreen offers a comprehensive warranty period, typically 12-24 months, against manufacturing defects and premature failure under normal operating conditions. Our after-sales support includes:

- Technical Assistance: Our team of experienced engineers and technical specialists is available to provide guidance on installation, maintenance, and troubleshooting.

- Prompt Issue Resolution: In the rare event of a product issue, our dedicated support team works swiftly to investigate and implement effective solutions, minimizing any potential disruption to your operations.

- Spare Parts Availability: We maintain inventory of standard backing plate designs and can rapidly produce custom replacements to ensure minimal downtime.

Delivery and Logistics

Understanding the critical timelines in industrial operations, MutoScreen is committed to efficient logistics and on-time delivery. Our streamlined production process and global shipping partnerships ensure that your Vibrating Screen Backing Plates reach you promptly and in perfect condition, wherever your operations are located.

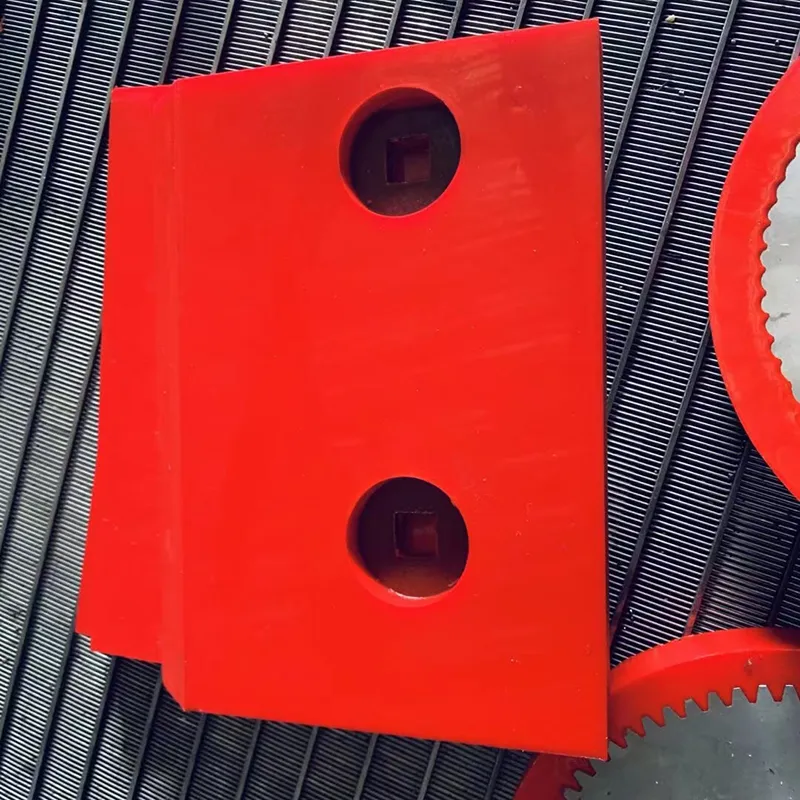

Fig 2: Finished backing plates, ready for shipment after final quality checks.

Professional FAQ: Addressing Your Key Concerns

Q1: What is the primary function of a Vibrating Screen Backing Plate?

The primary function of a Vibrating Screen Backing Plate is to provide robust structural support for the screen media (like polyurethane screens or wire mesh) and to efficiently transmit the vibrational energy from the exciter mechanism evenly across the screen surface. This prevents premature wear of the screen media, ensures optimal material separation, and protects the main screen frame.

Q2: What materials are typically used for Vibrating Screen Backing Plates, and why?

Common materials include high-strength low-alloy (HSLA) steels such as Q235, Q345, or equivalent ASTM/EN grades, chosen for their excellent balance of strength, weldability, and cost-effectiveness. For applications involving high abrasion or corrosion, specialized wear-resistant steels (e.g., Hardox, NM400/500 series) or stainless steels (e.g., 304, 316) are used to enhance durability and extend service life.

Q3: How does the manufacturing process ensure the precision of the hole patterns on the backing plate?

Precision hole patterns are critical for secure screen media installation. MutoScreen utilizes advanced CNC (Computer Numerical Control) punching and drilling machines. These machines are programmed with precise coordinates, ensuring hole diameters and center-to-center distances are maintained within extremely tight tolerances (e.g., ±0.5mm or 0.02 inches). This accuracy prevents screen media movement and premature wear.

Q4: What is the typical service life of a Vibrating Screen Backing Plate, and what factors influence it?

The service life can vary significantly, typically ranging from 3 to over 10 years. Key influencing factors include: the material quality and thickness of the backing plate, the abrasiveness and impact forces of the screened material, the operating environment (e.g., presence of corrosive agents), the frequency and magnitude of vibrations, and proper installation and maintenance. High-quality materials and precise manufacturing significantly extend life.

Q5: Can MutoScreen customize backing plates for non-standard vibrating screen models or specific application requirements?

Yes, customization is a core strength of MutoScreen. We offer comprehensive design and engineering services to produce bespoke backing plates tailored to specific vibrating screen dimensions, unique hole patterns, specialized material requirements (e.g., extreme wear or corrosion resistance), and challenging operational environments. We can work from client drawings, existing samples, or develop new designs based on application data.

Q6: How does the flatness of the backing plate affect overall screening performance?

The flatness of the backing plate is paramount. Any significant deviation can lead to uneven support for the screen media, causing localized stress points, premature wear, and sagging. This results in inconsistent vibration transmission, reduced screening efficiency, and potentially inaccurate material separation. MutoScreen ensures tight flatness tolerances to maximize performance and screen media lifespan.

Q7: What inspection standards do MutoScreen's Vibrating Screen Backing Plates adhere to?

MutoScreen adheres to a range of international and internal quality standards. Our overall quality management system is certified to ISO 9001:2015. Material selection complies with relevant ASTM, EN, or JIS standards. Welding procedures conform to ISO 3834 and AWS D1.1 (if applicable). Dimensional accuracy and flatness are inspected against engineering drawings which reference industry standards like ANSI B4.1 for hole tolerances.

Conclusion: Powering Your Efficiency with MutoScreen

The question "**what does a vibrating plate do for you**" transcends a simple query about a piece of equipment; it's an inquiry into operational efficiency, cost reduction, and sustainable industrial practice. The Vibrating Screen Backing Plate, often a humble component, is undeniably a linchpin in the performance and longevity of your vibrating screens. It is the silent workhorse that ensures your valuable polyurethane screens and other media perform optimally, delivering consistent separation, minimizing downtime, and ultimately, boosting your profitability.

MutoScreen, with its profound expertise in material science, precision engineering, and a commitment to rigorous quality control, stands as your trusted partner in providing superior Vibrating Screen Backing Plates. Our dedication to customized solutions, coupled with robust after-sales support and adherence to global standards like ISO 9001, ensures that every product we deliver is not just a component, but a strategic asset designed to enhance your operational resilience and competitiveness. Invest in MutoScreen's Vibrating Screen Backing Plates, and experience the tangible benefits of reliability, durability, and unmatched performance that directly translate into greater value for you.

References & Further Reading:

For more in-depth technical insights and industry discussions, consider exploring:

- "Advancements in Screening Technology for Mineral Processing" - Journal of Minerals Engineering (e.g., ScienceDirect - Minerals Engineering)

- "Understanding Wear Mechanisms in Mining Equipment" - SME Mining Engineering Handbook (e.g., Society for Mining, Metallurgy & Exploration)

- "The Role of Materials Science in Industrial Equipment Durability" - Materials Science and Engineering (e.g., ScienceDirect - Materials Science and Engineering: A)

- Industry forums and technical papers from associations like the National Stone, Sand & Gravel Association (NSSGA) or relevant metallurgical societies.