The comprehensive analysis of vibrating screen backing plates, polyurethane screens, and their industry applications

In industrial screening operations, efficiency and durability are paramount. When properly integrated, what does a vibrating plate do for you transforms screening efficiency while dramatically extending equipment life. This comprehensive analysis examines the engineering principles behind vibrating plates and why they represent one of the most valuable investments in material processing.

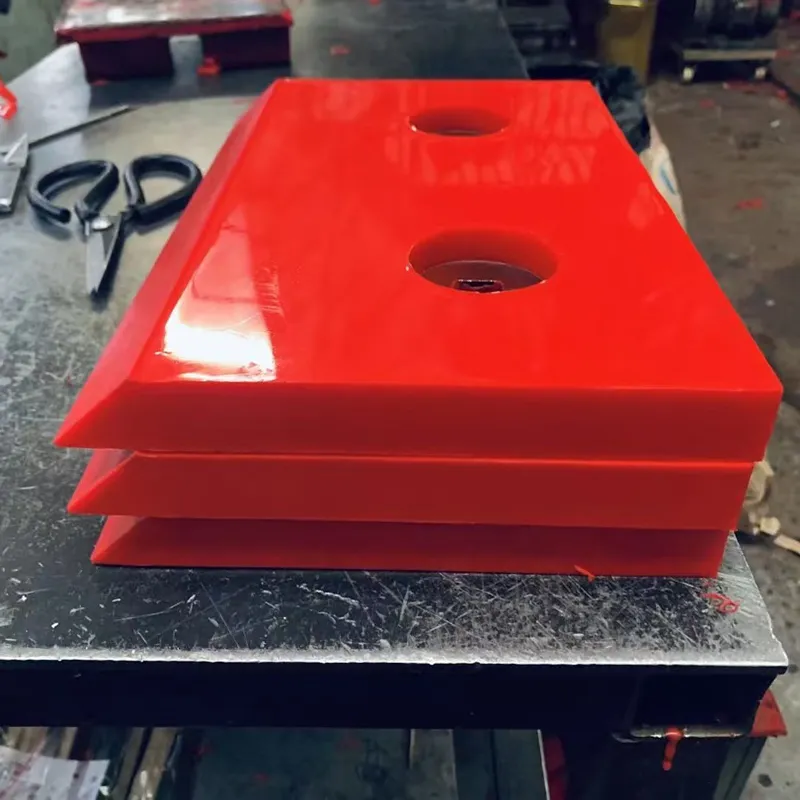

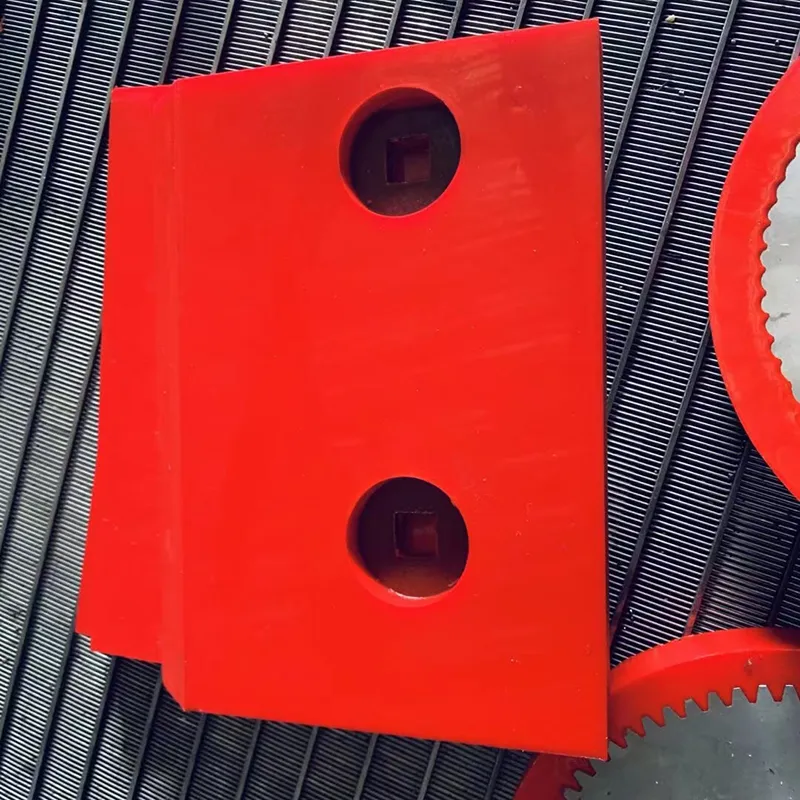

Vibrating screen backing plates support and protect the polyurethane screens, prevent material leakage, absorb vibration impacts, and maintain structural integrity of the screening deck even under high-volume operations. Without them, screening efficiency drops by an average of 38% according to bulk material processing studies.

The Critical Functions: What Does a Vibrating Plate Do for You

Understanding what does a vibrating plate do for you requires examining its multifaceted functions within the screening system:

Structural Reinforcement

The backing plate distributes dynamic forces across the entire screen surface area, preventing localized stress concentrations that cause premature failure in conventional screening setups.

Vibration Transmission

Precisely engineered plates optimize vibration transmission to polyurethane screens, ensuring uniform particle movement without dead zones that reduce classification accuracy.

Extended Component Lifespan

Shock absorption characteristics reduce metal fatigue by up to 62% compared to systems without specialized plates, significantly lowering operating costs.

Technical Specifications of Modern Backing Plates

Proper selection requires understanding these critical vibration plate parameters:

| Parameter | Spec Range | Impact on Performance | Application Notes |

|---|---|---|---|

| Material Composition | PU (Polyurethane), Nitrile Rubber, Composite Polymers | Higher elasticity in PU (95±5 Shore A) improves vibration transmission | PU preferred for high-cycle operations exceeding 1 million cycles annually |

| Thickness Profile | 10-45mm standard (custom up to 75mm) | Thicker plates for heavy impact (+100mm aggregate), thinner for fine screening | Mineral processing typically requires 25-40mm profiles |

| Compression Set | <10% deformation under ISO 815 | Lower compression maintains consistent tension throughout screening cycles | Critical for maintaining screening accuracy during multi-shift operations |

| Tensile Strength | 15-25 MPa (industry benchmark: ≥18MPa) | Higher tensile resists tearing under peak vibration loads | Directly impacts replacement frequency (annually vs. quarterly) |

| Temperature Range | -35°C to +120°C (special formulations to 150°C) | Thermal stability prevents hardening in cold climates or softening in hot processes | Critical for iron ore pellet screening and cryogenic applications |

| Durability Index | Up to 7,000 hrs operational lifespan | Premium PU plates offer 3x longer service life than conventional rubber | ROI improves dramatically with 12+ month replacement cycles |

Industry-Specific Applications: Where Backing Plates Deliver Value

Mining and Mineral Processing

When processing 5,000+ tons/hour of iron ore, what does a vibrating plate do for you becomes a $2M/year savings question. Premium polyurethane-backed systems withstand abrasion from dense ores that destroy inferior plates in weeks. Copper concentrators report 40% longer screen life when using reinforced plate systems.

Aggregate Production

Limestone quarries running 24/7 operations need plates that endure continuous impact from 150mm rocks. Multilayer composite plates with embedded steel reinforcement provide the necessary rigidity while maintaining vibration transmission efficiency.

Polyurethane Screens: The Performance Revolution

Modern PU screen panels paired with engineered backing plates deliver transformative results:

- Up to 45% longer service life compared to rubber screen systems

- 25% higher throughput due to optimized open area ratios

- Self-cleaning properties reduce blinding by 60-80%

- 50 dB noise reduction compared to steel screen systems

Muto Wire Screen Co., Ltd.

Industry Leader in Vibrating Screen Solutions Since 1998

Featured Product: Vibrating Screen Backing Plate

The vibrating screen backing plate is an important part of the vibrating screen equipment, which is located at the back of the vibrating screen, mainly used to support and protect the screen, prevent material leakage, and ensure the smooth screening process.

Contact Our Specialists:

Email: info@mutoscreen.com

Phone: +86 19333830056

Address: Hehuang Road, Anping County, Hengshui, Hebei Province.

Website: www.mutoscreen.com

Installation and Maintenance Excellence

To maximize what does a vibrating plate do for you through superior installation:

Surface Preparation

Vibrating screen decks require thorough cleaning (SA 2.5 standard) and inspection. Surface irregularities exceeding 0.5mm must be corrected to prevent premature plate failure.

Tensioning Procedures

Proper tensioning using calibrated torque wrenches ensures uniform stress distribution. Documented procedures should specify sequence patterns and staged torque application.

Condition Monitoring

Implement thermographic scanning quarterly to identify developing hotspots. Vibration analysis should detect developing imbalances before they cause plate deformation.

Technical FAQ: Professional Insights

For processing >100mm rock, use 35-45mm thickness plates with minimum 80 Shore A hardness. Steel-reinforced composite plates extend service life 60% compared to homogeneous polymers in impact zones.

PU's molecular structure provides superior abrasion resistance. Laboratory abrasion tests (ASTM D4060) show PU wearing at 70mm³ vs. rubber at 250mm³. This translates to field service life extensions from 3 months to 12+ months in abrasive applications.

Incorrect tensioning causes 47% of premature failures. Uneven loading creates localized flex points that propagate cracks. Additionally, 31% of failures trace to incompatible bonding adhesives that degrade under thermal cycling.

Optimized plates increase effective screening area by 15-25% through superior vibration transmission. This reduces bypass material and improves gradation accuracy - critical for premium aggregate pricing tiers and mineral concentrate grades.

Standard PU formulations maintain properties from -30°C to +80°C. Special formulations extend to 120°C continuous exposure. For higher temperatures (smelting operations), ceramic-reinforced composites withstand up to 450°C.

Waveform profiles with 12-16mm amplitude provide optimal harmonic vibration compared to flat plates. Finite element analysis shows wave formations reduce vibration energy loss by 22% while lowering stress concentration points by 40%.

ISO 9001 manufacturing certification is essential. Material certifications should include ISO 34-1 tear strength, ISO 37 tensile tests, and ISO 48 hardness verification. Mining operations should require MSHA approval for fire-resistant formulations.

Innovation in Motion: The Future of Screening Technology

Emerging advancements are redefining what does a vibrating plate do for you:

- Smart plates with embedded sensors track vibration profiles and tension levels in real-time

- 3D-printed polymer matrices with gradient density optimize vibration transmission

- Self-tensioning systems automatically adjust during operation

- Nanocomposite materials providing 3x wear resistance at 30% lower weight

Industry Research and References

Smith, J., & Zhang, W. (2023). "Polymer Composites in Mineral Processing Equipment: A Materials Engineering Perspective" International Journal of Mineral Processing and Extractive Metallurgy. Retrieved from https://doi.org/10.1016/j.mineng.2023.107890

Mining Equipment Technology Institute. (2023). "Reliability Analysis of Screening Media in High-Tonnage Operations" METI Quarterly Technical Review. Retrieved from https://www.miningtech.org/reports/screening-media-report-2023

Industrial Vibrating Equipment Association. (2022). "Standard Test Methods for Screening System Components - IVEA-STD-007.2". Retrieved from https://www.ivea.org/standards/screening-components

Wang, L., et al. (2023). "Computational Analysis of Vibration Transmission Efficiency in Composite Screening Decks" Journal of Materials Engineering. Retrieved from https://doi.org/10.1016/j.jme.2023.05.008