Screens are essential in the pulp and paper industry for fiber recovery, water filtration, and wastewater treatment. They help improve efficiency by removing impurities, reducing water consumption, and ensuring smooth processing.

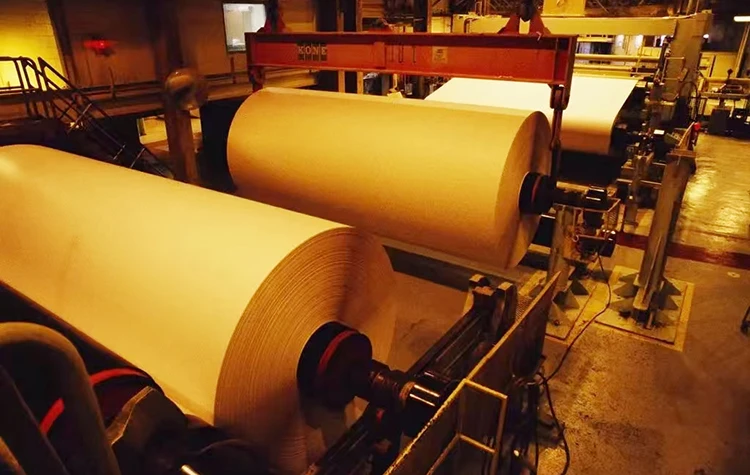

In the pulp production process, wedge wire screens separate wood chips, fiber residues, and oversized particles from the slurry. This ensures that only properly processed pulp moves forward in production, improving the quality of the final paper product. Rotary drum screens are often used to remove coarse materials from process water, reducing wear on downstream equipment.

During papermaking, screens play a crucial role in filtering and recycling process water. Fine screens remove suspended fibers and fillers, allowing treated water to be reused in production. This helps reduce water consumption and operational costs while improving sustainability. Wedge wire screens are particularly effective in dewatering applications, helping remove excess moisture from pulp and paper sludge.

Screens are also essential in wastewater treatment for the pulp and paper industry. The industry generates high volumes of wastewater containing fibers, suspended solids, and organic pollutants. Screens help separate fibers from wastewater before biological or chemical treatment, reducing COD and BOD levels. By capturing and recovering valuable fibers, screens contribute to cost savings and resource efficiency.

Modern paper mills are implementing advanced screening technologies to improve water reuse and reduce environmental impact. Self-cleaning screens ensure continuous operation with minimal maintenance, enhancing efficiency and reliability. By integrating effective screening systems, the pulp and paper industry can achieve greater sustainability while maintaining high production quality.