Screens are an essential component of wastewater treatment systems, used to remove solids and debris from sewage and industrial effluents before further treatment. Effective screening prevents clogging, reduces wear on downstream equipment, and enhances overall treatment efficiency.

In municipal wastewater treatment plants, bar screens are installed at the inlet to capture large objects like plastics, rags, and wood, preventing damage to pumps and pipelines. Fine screens, such as drum screens and step screens, remove smaller suspended solids, reducing the load on biological treatment units. Wedge wire screens are particularly valuable in wastewater treatment due to their high filtration accuracy and durability.

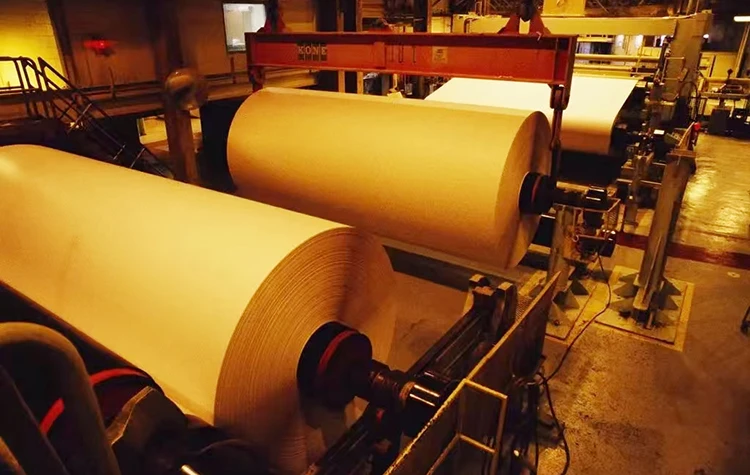

Industrial wastewater treatment facilities also rely on screens to manage complex waste streams. For example, in food processing plants, screens separate organic solids, fats, and grease from wastewater before biological treatment. In the pulp and paper industry, wedge wire screens filter out fibers and suspended solids, reducing chemical oxygen demand (COD) and biochemical oxygen demand (BOD) levels.

Self-cleaning screens are increasingly used in modern wastewater treatment plants to ensure continuous operation with minimal maintenance. These screens automatically remove trapped particles, preventing blockages and optimizing system performance. Screens are also essential in wastewater reuse applications, filtering treated water before it is discharged or repurposed for irrigation, industrial processes, or cooling water systems.

By integrating advanced screening technologies, wastewater treatment facilities can improve efficiency, reduce environmental impact, and enhance the quality of treated effluent, making water reuse more viable in various industries.