Coarse Screening in Water Treatment - Efficient Wastewater Coarse Screens for Reliable Filtration

- Introduction to coarse screening in water treatment

- Importance and functions of coarse screen in wastewater treatment

- Technological advancements and operational efficiencies

- Comprehensive comparison of leading manufacturers and system types

- Customization options and integration with existing infrastructure

- Case studies and real-world applications

- Conclusion: Future outlook of coarse screening in water treatment

(coarse screening in water treatment)

Introduction to Coarse Screening in Water Treatment

Coarse screening in water treatment serves as the first line of defense against large debris and unwanted solids entering the treatment process. Municipal and industrial treatment plants rely on robust screening systems to achieve significant reductions in operational downtime, equipment damage, and costly repairs. Coarse screens, designed to intercept solid waste like leaves, plastics, branches, and rags, typically filter particles larger than 6 mm. With global water consumption reaching over 4 trillion cubic meters per year, the need for efficient coarse screening has grown increasingly paramount. Efficient screening not only translates into operational safety but also meets ever-tightening regulatory standards.

Importance and Functions of Coarse Screens in Wastewater Treatment

The core task of a coarse screen in wastewater treatment is to remove large floating contaminants before they enter pumps, pipes, or subsequent treatment stages. Failure to implement proper screening can result in significant equipment abrasion, blockages, and additional maintenance costs. In urban wastewater systems, solid loadings can exceed 150 mg/L during storm events, highlighting the necessity for dependable screening mechanisms. Additionally, coarse screening enhances downstream treatment efficiency; removing up to 30% of total suspended solids (TSS) prior to primary clarification, reducing the organic loading on biological reactors and lowering overall energy consumption.

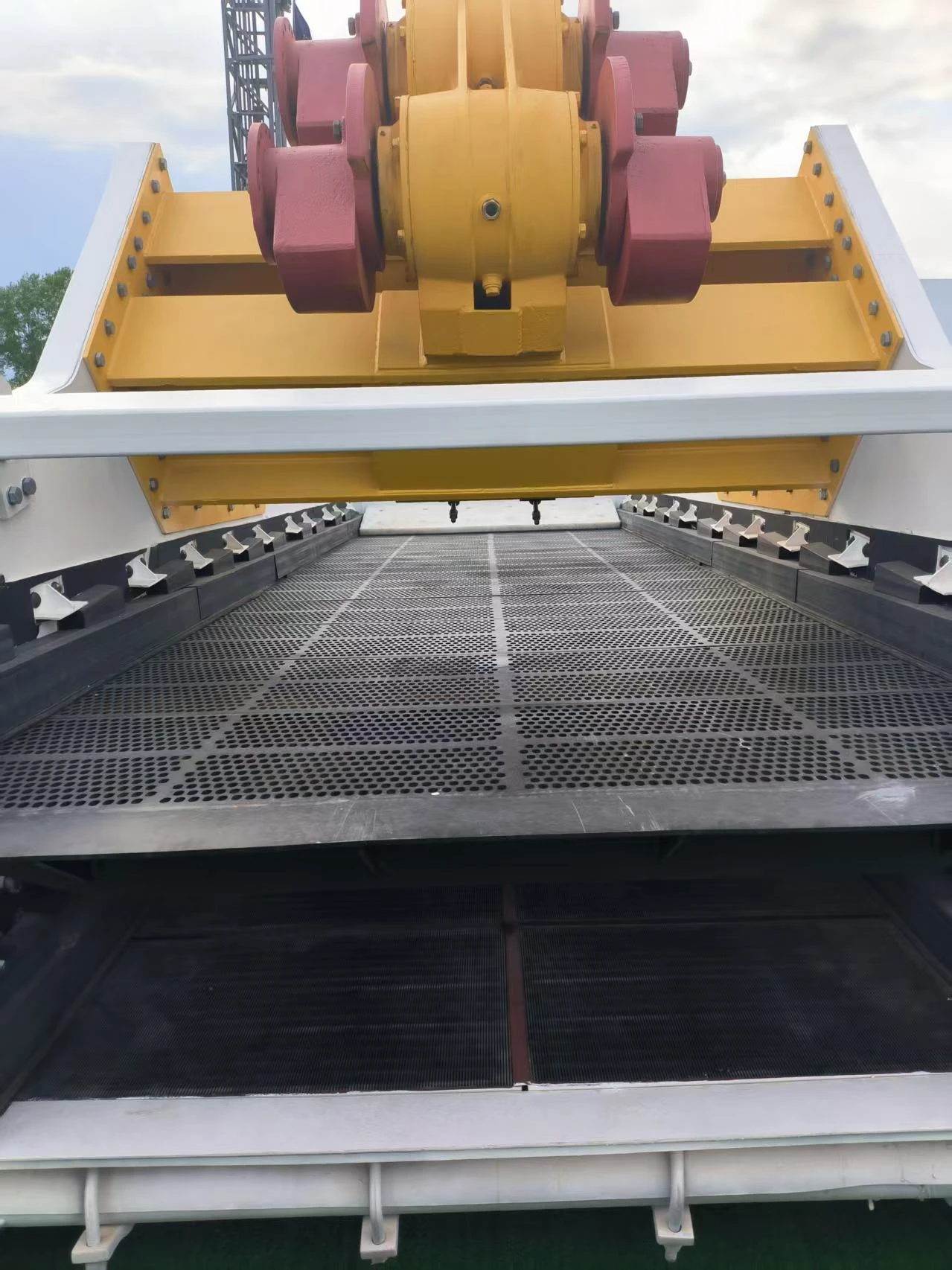

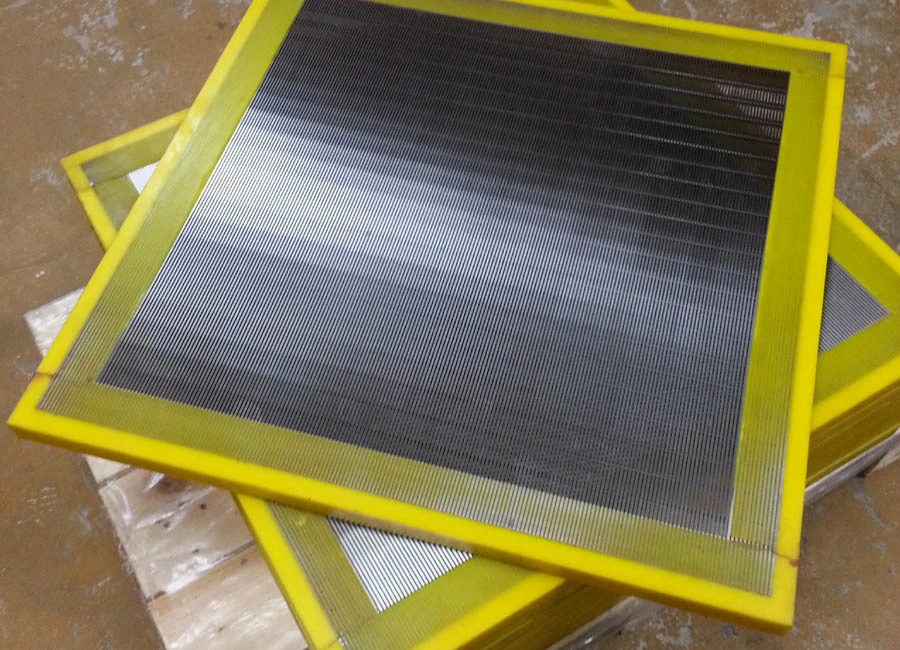

Technological Advancements and Operational Efficiencies

Recent advancements in coarse screening technology have significantly improved performance and reliability. Modern automatic bar screens, rotary drum screens, and step screens utilize high-tensile stainless steel for corrosion resistance and durability. Intelligent controls and self-cleaning mechanisms reduce manual intervention, resulting in up to 40% reduction in maintenance costs. In wastewater systems where total influent flow can surpass 500,000 m³/day, the installation of scalable, automated screens ensures uninterrupted service. High-efficiency models now deliver up to 98% removal rates for coarse particulates, keeping pace with the demands of growing urban agglomerations and stricter operational protocols.

Comprehensive Comparison of Leading Manufacturers and System Types

Selecting the most suitable coarse screening solution requires a careful comparison of technical specifications, cost, performance, and post-installation support. Below is a comparative analysis of leading manufacturers, showcasing various system types and their distinguishing features:

| Manufacturer | Screen Type | Material | Slot/Bar Spacing (mm) | Flow Capacity (m³/h) | Automatic Cleaning | Average Removal Rate (%) | Estimated Maintenance Cost (USD/year) |

|---|---|---|---|---|---|---|---|

| HydroScreen Technologies | Automatic Bar Screen | 316 SS | 10 – 25 | 50,000 – 200,000 | Yes | 96 | 8,200 |

| Xylem – Leopold | Rotary Drum Screen | 304 SS | 6 – 12 | 15,000 – 120,000 | Yes | 98 | 6,700 |

| Ovivo | Step Screen | 316 SS | 6 – 10 | 10,000 – 50,000 | Yes | 95 | 7,800 |

| JWC Environmental | Fine-Coarse Combined | Fiberglass, SS | 6 – 23 | 5,000 – 60,000 | Yes | 94 | 9,400 |

| Huber Technology | Inclined Bar Screen | SS | 8 – 20 | 8,000 – 80,000 | Yes | 96 | 7,200 |

The above data demonstrates notable differences in removal efficiency, cost, and construction, empowering procurement managers to align their choices with site-specific needs and budget constraints.

Customization Options and Integration with Existing Infrastructure

Modern treatment facilities increasingly demand tailor-made coarse screening solutions to address unique site constraints, variable loadings, and fluctuating flow rates. Leading manufacturers offer customization options such as adjustable bar spacings, variable screen inclinations, corrosion-resistant materials, and custom dimensions to fit tight installations. Integration with SCADA and real-time monitoring enables predictive maintenance and rapid fault detection. Engineering teams can opt for retrofitting coarse screens into legacy infrastructure, reducing capital expenditure by up to 35% compared to complete overhauls. Collaborative design approaches ensure compliance with regulatory discharge limits while maximizing throughput and operational uptime.

Case Studies and Real-World Applications

Real-world deployments underscore the practical benefits of advanced coarse screening technologies. For instance, a major metropolitan wastewater authority in the United States installed automated bar screens, resulting in a 70% reduction in unscheduled downtime and a 25% decrease in annual maintenance expenditure. In Southeast Asia, a textile manufacturing plant retrofitted step screens, preventing clogging during monsoon peaks and maintaining continuous plant operation. Municipalities integrating real-time monitoring with coarse screening have reported up to 20% enhancements in downstream treatment capacity. These operational gains translate into reduced environmental footprint, improved water quality, and significant cost savings over the asset lifecycle.

Conclusion: Future Outlook of Coarse Screening in Water Treatment

Advancements in coarse screening in water treatment will continue to raise the bar for performance, efficiency, and adaptability. As water scarcity and population growth drive stricter regulations, robust screening technologies will remain fundamental to sustainable wastewater management. Emerging trends include the use of smart sensors, AI-driven monitoring, and enhanced materials engineering to boost removal rates and minimize OPEX. As a critical step in the treatment process, the ongoing evolution of coarse screens will shape the ability of global water utilities to deliver safe, reliable, and cost-effective services under increasing pressures from industry, climate, and urbanization.

(coarse screening in water treatment)