As mineral processing, metallurgy, and water treatment industries advance, the demand for robust, high-efficiency screening media such as the polyurethane sieve plate has surged. This article provides a deep-dive into polyurethane screening technologies—covering industry trends, product specs, technology flows, manufacturer comparison, and real-world application cases. This resource is designed for engineers, procurement specialists, and plant managers seeking the best-in-class solution for screening and dewatering needs.

1. Market Trends and Industry Outlook for Polyurethane Sieve Plate

The global polyurethane sieve plate market is projected to reach USD 850 million by 2029, growing at a CAGR of 6.5% (source: MarketsandMarkets, 2023). Key growth drivers include:

- Increasing adoption in mining and aggregate industries due to superior abrasion resistance and longer service life versus traditional steel or rubber screens.

- Higher demand from the dewatering screen market, especially in wastewater treatment, coal washing, and precious metal extraction.

- Growing focus on efficient particle separation with energy-efficient, corrosion-resistant solutions.

2. Understanding Polyurethane Sieve Plate & Related Products

Polyurethane screen technology, encompassing poly screen panels and slot screen decks, is engineered to outperform steel and wire mesh equivalents for highly abrasive and corrosive environments.

| Parameter | Range/Spec | Industry Standard |

|---|---|---|

| Material | Polyurethane (PU), MDI/TDI based | ISO 9001, ANSI/AISI 430 |

| Opening Slot Size | 0.075 mm – 120 mm | Customer/industry customized |

| Shore Hardness | 60A – 95A | ASTM D2240 |

| Panel Dimensions (mm) | 305x610, 500x1000, OEM sizes | OEM/Standard modular |

| Screening Efficiency | >92% | ISO 2395:1988 |

| Temperature Resistance | -30°C to 80°C (peaks at 120°C) | ISO 1798 |

| Chemical Resistance | Strong (pH 2-12) | ISO 1817 |

| Working Life | 6,000-18,000 hours (application dependent) | En/ISO 178 |

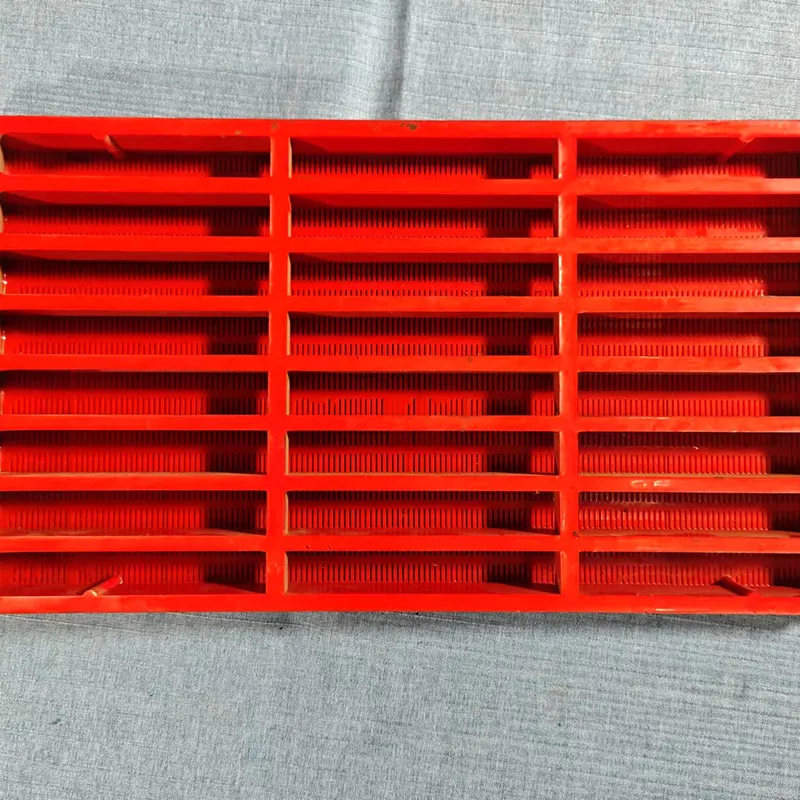

- Polyurethane Sieve Plate: Modular, pre-formed panel made from high-resistance polyurethane, designed for high-frequency vibrating screens.

- Polyurethane Screen: Broader term for any mesh/panel made with PU that provides the separation surface in a vibrating or static screen.

- Poly Screen Panels: Modular, easily replaceable screen modules used in mining or recycling screens.

- Dewatering Screen: Specialized vibratory screens designed to remove moisture from particles during or post-separation.

Score: 1-10 (wear resistance/noise), absolute values (open area, weight, working life).

3. Polyurethane Slot Screen Plate: Manufacturing Process Explained

① Raw Material Preparation

- High-quality PU elastomer pellets (MDI or TDI based) are sourced.

- Resins and cross-linkers are batch tested per ISO 9001.

② Precision Mixing & Pre-polymerization

- Automated mixing of prepolymer and curatives ensures homogeneity (ANSI/ASTM D3182).

③ Molding / Casting

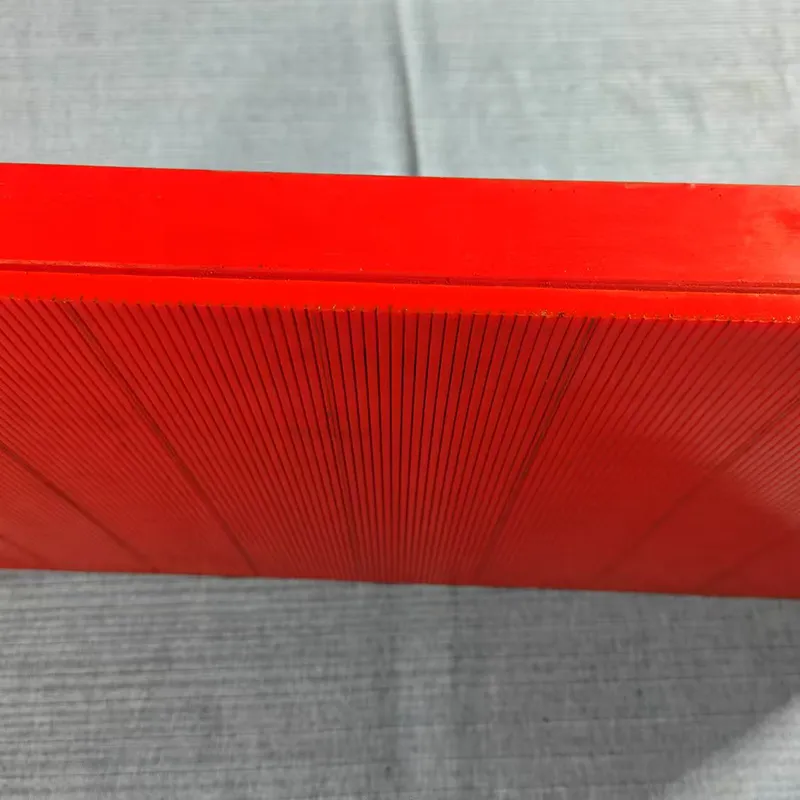

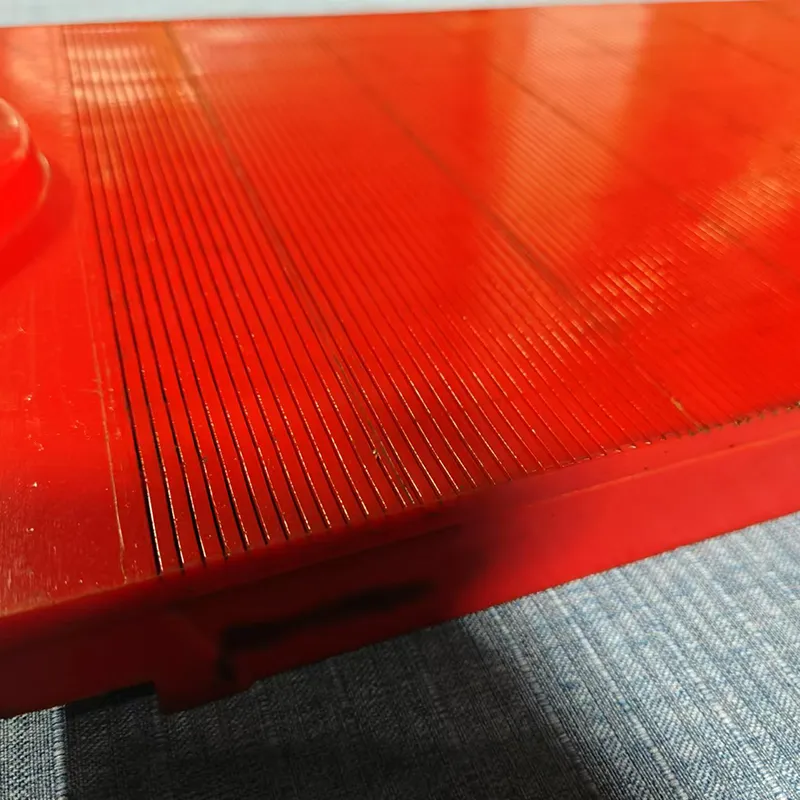

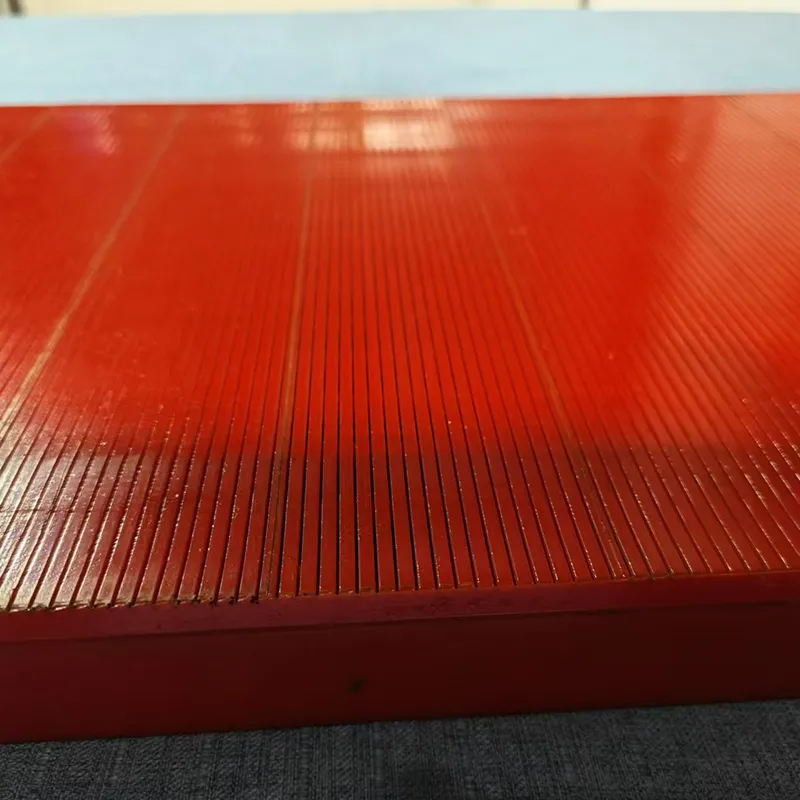

- CNC-machined molds guarantee consistent slot tolerances (±0.05mm).

- Injection or vacuum casting is used based on panel thickness/design.

④ Curing (Thermal Process)

- Panels are cured in controlled ovens with PID regulation (ISO 11357-2).

⑤ Demolding & CNC Edge Finishing

- Edges, slots, and mounting holes are post-processed for tolerance.

⑥ Quality Control & Testing

- Tensile, elongation, and wear tests (ASTM D412, ISO 9001 batch release).

⑦ Packaging & Delivery

- Each panel is laser-marked for traceability and ISO documentation.

| Model | Slot Width (mm) | Thickness (mm) | Panel Size (mm) | Hardness (Shore A) | Open Area (%) | Estimated Lifespan (h) | Certifications |

|---|---|---|---|---|---|---|---|

| MUTO-SLP10 | 0.1 - 2.5 | 25 | 305x610 | 85 ±3 | 44-48 | 12,000 | ISO 9001 |

| MUTO-SLP20 | 2.5 - 8 | 30 | 500x1000 | 90 ±2 | 52-58 | 15,000 | ISO 2395 |

| MUTO-DW30 | 0.5 - 3 | 25 | 650x1040 | 92 ±1 | 40-48 | 10,000 | ASTM D2240 |

| MUTO-WC40 | 4 - 12 | 34 | 1000x1200 | 88 ±3 | 60-63 | 18,000 | ISO 178 |

4. Why Choose Polyurethane Sieve Plate? Key Technical Advantages

- Superior Wear and Tear Resistance: PU sieve plates last 3-5x longer than steel, especially under high-frequency impact.

- Customizable Slot Geometry: Fine slot to coarse slot possible via CNC/casting technology.

- Significant Noise Reduction: Polyurethane absorbs vibration energy, lowering screening noise by approx. 12-17 dB.

- Lightweight Design: Delivers ~45% weight saving, simplifying installation and changeover.

- Corrosion & Chemical Resistance: Handles acids, alkalis, and solvents—used in petrochemical and wastewater applications.

- High Screening Efficiency & Low Blinding: Tapered self-relieving slot profile minimizes clogging, especially in sticky ore conditions.

- Meets Key Standards: Complies with ISO 2194, DIN 4187, and ASTM D4060 for screen panels in mining and industrial settings.

5. Polyurethane Screen Panels Manufacturers: Global Comparison

- Years in Service: 17+

- Certifications: ISO 9001, ISO 2395

- Key Markets: Asia, Africa, Europe

- OEM Customization: Yes (Design, size, logo)

- Lead Time: 7-20 days

- Website: MUTO Polyurethane Slot Screen Plate

- Years in Service: 80+

- Certifications: ISO 14001, OHSAS 18001

- Global Plants & Support

- Advanced Material Formulations

- Premium Pricing, Longer Lead

- Specializes in modular poly screen panels

- Rich in mining partner network

- Customization: High (slot, aperture shape, branding)

- Focused on US, Latin America

- Economical, fast delivery Asia/Africa

- Meets ISO 9001

- Limited technical support vs. global giants

6. Customization Options & Engineering Support

Polyurethane Slot Screen Plate panels can be tailored for particle gradation, throughput capacity, slot profile (parallel/tapered), size, and bolt/clamp styles. Engineering teams work with clients to:

- Optimize open area and slot geometry according to feed characteristics

- Design heavy-duty or fine screening panels for dewatering screen units

- Integrate anti-blinding bars, self-cleaning profiles

All custom solutions are supported by 3D CAD design files, prototype samples, batch traceability, and ongoing technical consulting.

Lead time: 7-20 working days based on order volume and slot complexity.

7. Application Scenarios and Case Studies

- Mineral Processing Plants: Installed as main deck media in high-frequency vibratory screens, enduring abrasive iron ore, gold, or coal streams.

- Municipal & Industrial Water Treatment: Used in dewatering screen units to filter suspended matter at sewage and recycling centers.

- Sand & Aggregates: Polyurethane sieve plate modular panels handle sand separation at quarries—with lifecycles exceeding 12,000 hours.

- Chemical & Petrochemical Filtration: Anti-corrosive PU panels installed in aggressive process media, reducing panel change-out by 40%.

“Switching to MUTO’s polyurethane sieve plate reduced our noise levels by over 15 dB and maintenance costs were cut in half. Screening efficiency climbed to 94%.” — Raymond I., Plant Manager, Indonesia (2023)

In 2023, a copper concentrator in Chile replaced conventional steel panels with polyurethane sieve plate modules. Results included a 20% throughput increase and maintenance interval extension from 2 months to 7 months (source: Company data).

8. Professional FAQ on Polyurethane Sieve Plate

9. Delivery, Warranty and After-sales Support

Delivery Time: 7 to 21 working days from order confirmation, depending on complexity and order size.

Warranty: 12-24 months against material and manufacturing defects (ISO/ASTM D4060 covered).

Customer Support: 24/7 pre & after-sales technical assistance, spare panel stock in strategic hubs.

Documentation: Product batch traceability, test reports, installation guides, and regulatory compliance delivered with each order.

10. Conclusion and Further Reading

The polyurethane sieve plate and advanced poly screen panels have revolutionized the screening industry—offering unmatched service life, efficiency, and adaptability. By partnering with certified manufacturers and leveraging advanced engineering, plants can maximize ROI and minimize downtime.

- "Polyurethane Screens – The Future of Screening in Mining," Mining Engineering Forum, Jan 2024. Read online.

-

"Slotted Polyurethane Screen Panels for Aggregate and Dewatering," World Journal of Screening Technology, Vol. 38, 2023.

Journal Reference - Metso Outotec, "Polyurethane Screening Media," Official Site

- International Journal of Mineral Processing, "Field Performance Evaluation of Polyurethane Modular Panels," 2022.

- ISO 9001 & ISO 2194 Standards, via ISO Organization