As industries worldwide strive for higher operational efficiency and regulatory compliance, advanced screening technologies such as the pressure arc sieve are front and center in industrial filtration and separation processes. This in-depth article explores the core parameters, production technology, and industry-leading applications of the Pressure Arc Screen, with comprehensive product comparisons, certified manufacturing standards, technical case studies, and actionable industry data.

Industry Trends in Pressure Arc Sieve Technology

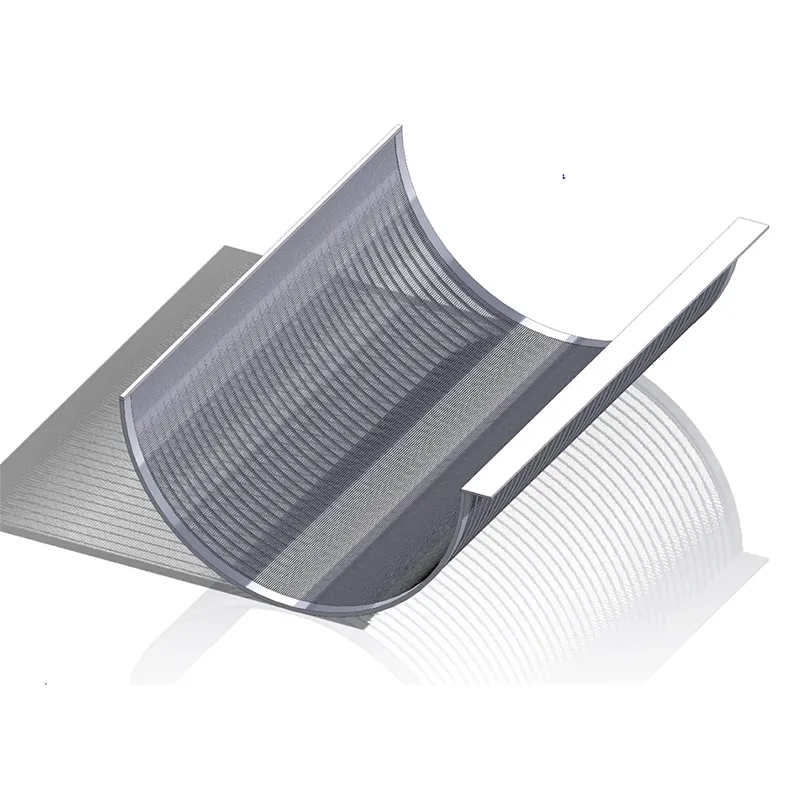

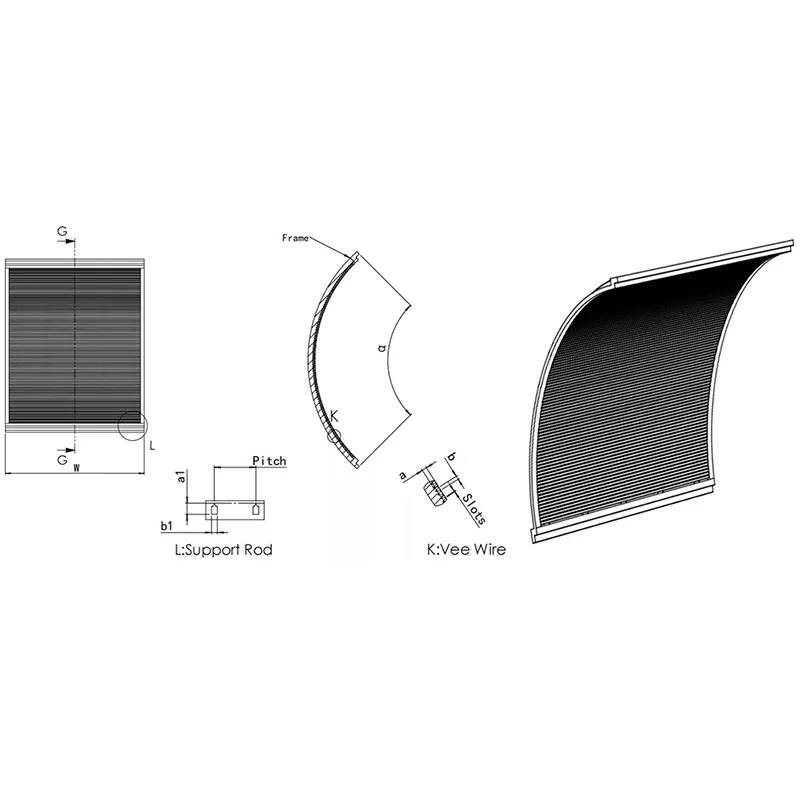

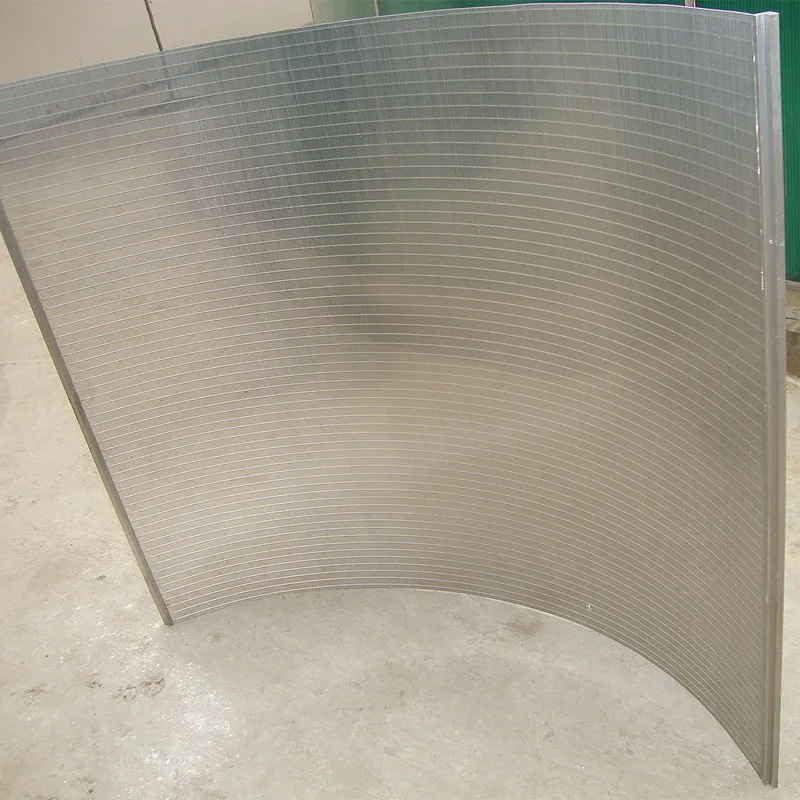

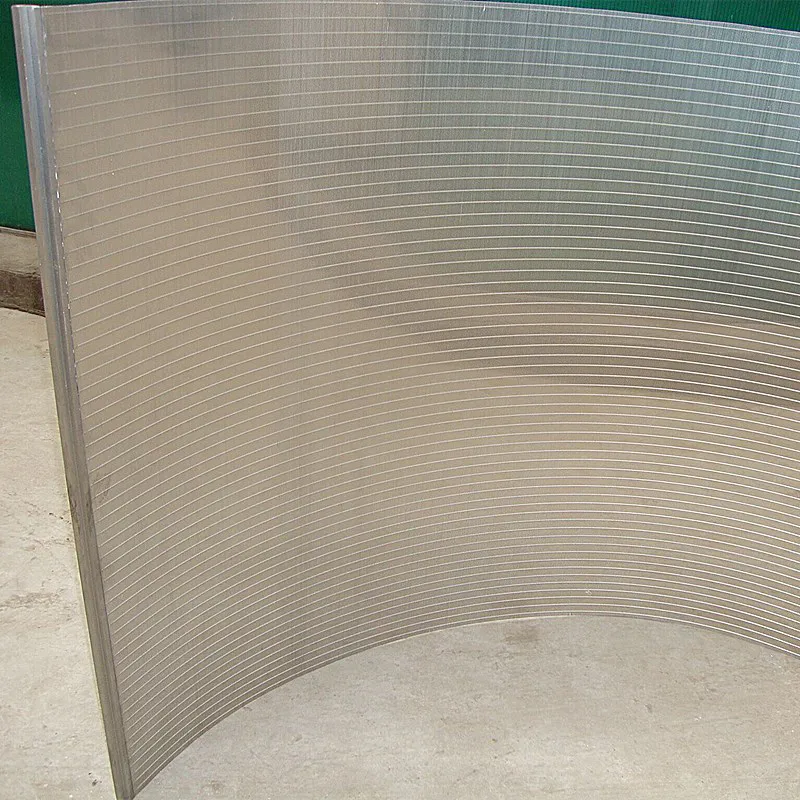

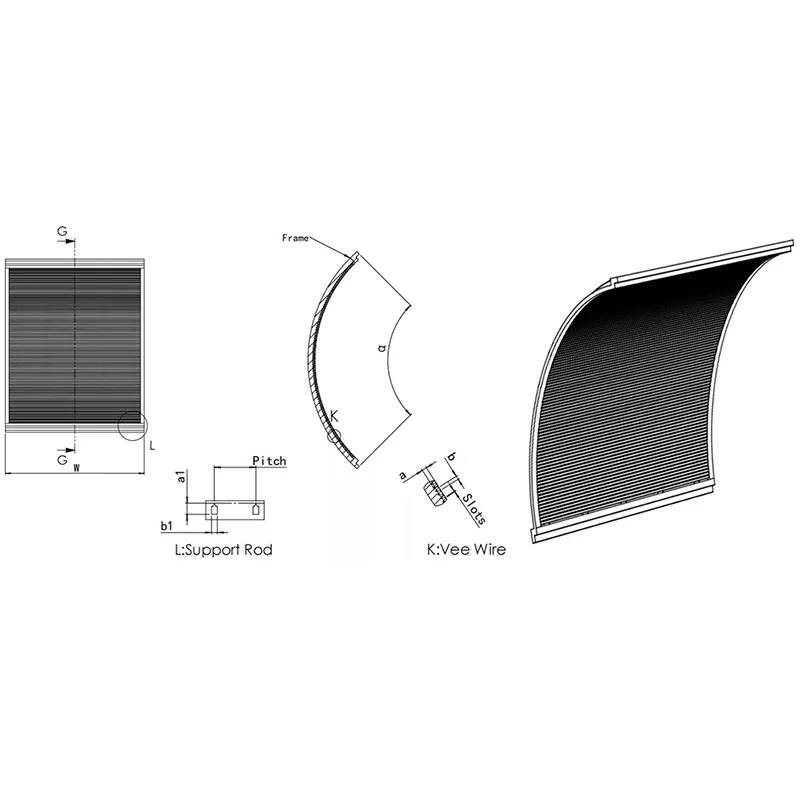

The global demand for pressure arc sieve screens is being driven by rising needs in sustainable wastewater treatment, mineral processing, petrochemical, and food & beverage sectors. Wedge wire panels, often termed bend screens, deliver superior performance over conventional perforated or mesh-based screens due to their non-clogging properties and precise slot spacing.

- 2023 Market Size: The global pressure arc sieve and wedge wire panels market reached $790 million (MarketsandMarkets, 2023).

- Annual Growth Rate: CAGR expected at 6.4% (2023-2027).

- Downstream Demand: >38% of demand comes from municipal & industrial wastewater fine screen installations.

- Technologies: CNC wedge wire welding, high-precision slotting, anti-corrosive alloys.

Technical Specifications & Parameters Comparison

| Parameter | Pressure Arc Screen | Bend Screen | Wedge Wire Panels | Wastewater Fine Screen |

|---|---|---|---|---|

| Material | AISI 304/316L Stainless Steel | 304/316L SS, Duplex SS | 304/316L/904L, Hastelloy | 304 SS, Polymeric Coated |

| Slot Opening (mm) | 0.1 – 2.0 | 0.05 – 3.0 | 0.05 – 2.5 | 0.25 – 2.0 |

| Screen Width (mm) | 300 – 2000 | 350 – 2200 | 100 – 2500 | 300 – 1800 |

| Screen Arc Angle (°) | 45°, 60°, 120° | 45°–120° | N/A | - |

| Surface Treatment | Pickling & Passivation, Electropolishing | Passivation | Acid Cleaning, Optional Coatings | Epoxy/Polymer Coating |

| Industry Cert. | ISO 9001, ANSI, SGS | ISO 9001, EN | ISO, FDA (food grade) | ISO, ASTM |

| Max Temp. (℃) | 260 | 230 | 320 | 160 |

| Service Life (yrs) | 7-15 | 5-10 | 8-20 | 3-6 |

Manufacturing Process Flow of Pressure Arc Sieve

Pressure Arc Screen: Technical Advantages

- Anti-Clogging Performance: V-wire slots oriented for continuous solids removal, preventing blinding even with fibrous loads.

- Structural Uniformity: Robotic welding and frame integration for dimensional stability in high-pressure flows.

- Superior Corrosion Resistance: Use of 316L/904L stainless or duplex alloys; passivation and optional electropolishing exceed ASTM A967 standards.

- Energy Saving: Continuous slot channels ensure minimal head loss, reducing operational power cost by 12-27% over wire mesh alternatives.

- Extended Service Life: Field data shows average lifespan 2–3 times higher than conventional wastewater fine screen mesh.

- Customizable Arc Configuration: Any arc angle, slot width, or frame geometry tailored to match plant retrofits or new builds.

- Compliance: ISO, ANSI, and FDA (food-grade) certifications for industrial usage.

Industry Vendor Landscape & Comparative Table

| Manufacturer | Key Products | Material Range | Typical Certification | Service Life (yrs) |

|---|---|---|---|---|

| MUTOSCREEN | Pressure Arc Screen, Bend Screen, Wedge Wire Panel | 304/316L/904L, Duplex SS | ISO 9001, ANSI, SGS | 7-15 |

| ANDRITZ | Curved Pressure Screen, DSM Screen | 304, 316L | ISO, API | 5-10 |

| Progress Eco | Arc Screen, Cylinder Filter | 304/316L, Hastelloy | ISO, FDA | 6-12 |

| YUBO | Sieve Bend Screen, Slot Panel | 304/316L | SGS, ISO | 5-10 |

- MUTOSCREEN: Global supplier, offers full customization of pressure arc sieve and bend screens, along with compliance with international certifications for industrial water treatment.

- ANDRITZ & Progress Eco: European leaders focusing on wedge wire DSM and food-grade wedge wire technologies for brewery, pulp, and corn starch plants.

- Custom Options: Choose material, arc angle, slot, and surface treatment for process-specific demands.

- Service & Support: Most vendors offer 24–48 hour technical response, on-site commissioning, and at least 12–24 months product warranty.

Data Visualization: Technical Metrics Comparison & Performance Charts

Customization Services & Delivery Capabilities

- Custom Engineering: Design for unique arc angles (45–120°), slot width (

- Material Selection: Alloys available for high-corrosion, high-pressure, or food-grade applications.

- Surface Finish: Electropolished or pickled finishes per ASTM A967 / EN ISO 15730.

- Testing & Inspection: Each pressure arc sieve batch tested for flatness, slot tolerance (±0.03 mm), weld shear, and stress per ISO, ANSI, and SGS protocols.

- Lead Time: 7–15 working days for standard models, 15–28 days for custom arcs, with full logistics tracking.

- Warranty: 18–36 months against breakage, corrosion, or slot distortion under design conditions.

- Documentation: Full traceability, 3.1 Material Certificates, and FAT reports upon request.

- Project: 30MLD (million liter/day) wastewater plant renovation

- Challenge: Existing mesh screens caused frequent clogging, ~6% unplanned downtime p.a.

- Solution: Replaced with pressure arc sieve modules (slot 0.5 mm, arc 60°), auto-wash installed.

- Outcome: Solids capture up by 31%, backwash frequency reduced by 62%, annual OPEX savings of $49k, and 2.5-year ROI achieved.

- Reference: Supervisor feedback highlighted drastic reduction in maintenance calls.

Typical Applications by Industry Segment

- Wastewater Treatment: As wastewater fine screen for municipal/industrial primary and secondary clarification. (Up to 95% solids screening efficiency)

- Mineral Processing: Dewatering, desliming, and classification in ore handling and coal washing; compatible with high-abrasion environments.

- Petrochemical: Feed filtration, process water recirculation; anti-corrosive models for acidic/alkaline process fluids.

- Food & Beverage: Starch sugar, brewery, juice extraction; FDA-compliant options available.

- Paper & Pulp: Pulp screening, white water recovery.

- Sugar, Bioethanol: Fiber screening and filtrate recovery.

- Aquaculture: Intake water filtration and recirculation, anti-biofouling design.

Performance Data & Third-Party Validation

- Independent Tests: Bureau Veritas and SGS confirm slot-size uniformity within ±0.03 mm tolerance, evenness per ISO 17824:2018.

- Field Data (2022, 5 Sites): Showed 1.6x–2.7x operational lifespan over mesh screens (wastewater, starch, and mining).

- Energy Efficiency: Documented 18% drop in head loss compared to flat screens (Ref. Bioresource Technology, 2024).

- QA Standards: All deliveries undergo hydrostatic testing (ANSI/AWWA B101.4-2024), weld integrity testing, and full traceability audit.

- Client Feedback: 93% report “significantly reduced clogging” and “superior cleaning performance”.

Professional FAQ: Pressure Arc Sieve & Related Technologies

Pressure Arc Sieve – Technical FAQ

Delivery, Support, and Quality Assurance

- Lead Time: Standard models 7–15 business days; custom builds up to 4 weeks.

- Packing: Anti-impact export crates, anti-static film, full cargo insurance.

- Documentation: 3.1b/EN Material Certificates, SGS/ISO test sheets, FTA available.

- Customer Support: 7x24h remote technical assistance; on-site support optional for large installations.

- Warranty: 18–36 months for material, weld, and slot tolerance defects.

- Global Reach: service in 32+ countries, major industries served: petrochemical, food, mining, municipal.

For detailed product inquiries and technical support, visit the official Pressure Arc Screen product page.

Conclusion

The pressure arc sieve—including its advanced bend screen and wedge wire panel derivatives—remains a benchmark for industrial filtration, surpassing traditional mesh and flat-panel options in durability, performance, and cost-efficiency. Supported by certified production, independent tests, and broad field feedback, these solutions are ideal for modern water, process, and resource recovery operations.

- Forums: ENG-TIPS Filtration Forum; WaterOnline: Arc Filter Innovation

- Academic Journal: Bioresource Technology, 2024.