Main Keyword: wedge wire basket | Related: wedge wire screen basket, what is a wedge wire screen, what is wedge wire

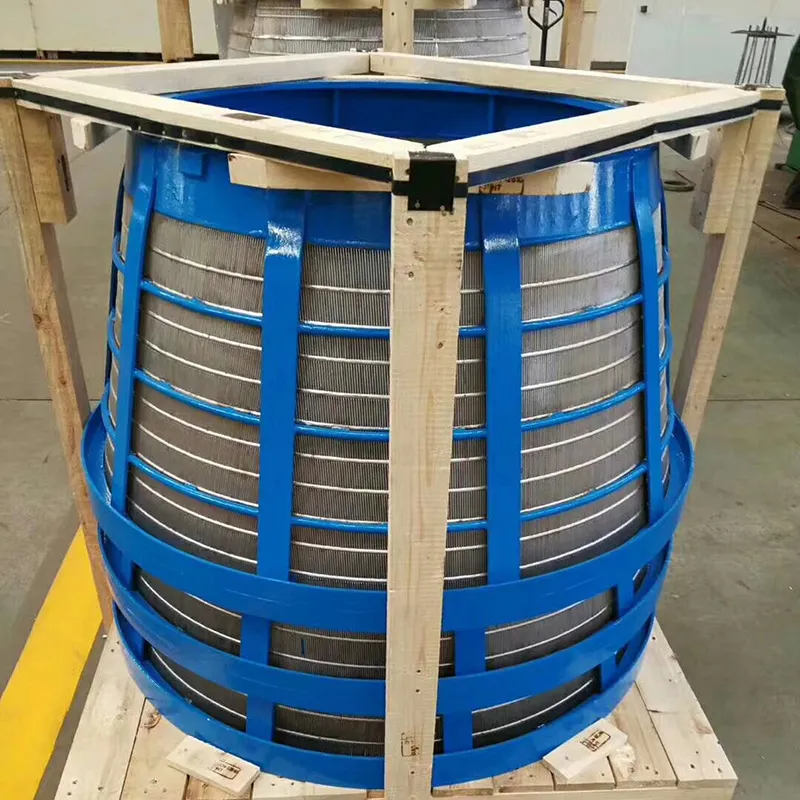

Centrifugal Baskets are a core solution in separation and filtration technology, specifically engineered for robust industrial processes where reliability, precision, and lifecycle are critical. In this comprehensive guide, we delve into the manufacturing technique, technological parameters, industry trends, application fields, and authoritative comparisons of wedge wire basket and wedge wire screen basket, empowering you to choose and customize your optimal solution for 2024 and beyond.

What Is Wedge Wire, What Is a Wedge Wire Screen, and What Is a Wedge Wire Basket?

- Wedge Wire Screen: Slotted filtering element made of V-shaped wire welded onto support rods.

- Wedge Wire Basket: Screen baskets utilizing wedge wire construction for centrifugal separation, filtering, and dewatering in harsh industrial environments.

- Main Attributes: High open area, precise slot control, mechanical strength, anti-plugging, and long lifecycle.

2024 Industry Trends for Wedge Wire Baskets

- Growing Demand: The wedge wire basket global market was valued at USD 790 million (2023, Statista), with CAGR of 6.2% projected through 2026, propelled by mining, petrochemical, sugar, and wastewater sectors.

- Material Innovation: Wider adoption of Duplex & Super Duplex stainless steel, high-nickel alloys for improved anti-corrosion and extended lifetime.

- Smart Manufacturing: Real-time quality control, CNC automation, and digital twin design are reshaping customization and consistency.

- Eco Compliance: ISO 14001, REACH, and FDA/USP Class VI compliance are prominent purchasing requirements, especially for food and pharma industries.

- Lifecycle Value: End-users increasingly require >30% longer service life and lower maintenance for sustainability and OPEX savings.

Wedge Wire Basket Manufacturing Process: Workflow & Technical Insights

High-specification stainless steel (304, 316L, Duplex, etc.) or special alloys selected according to industry/media.

V-wire/profile wire is shaped by precision rolling; support rods are prepared according to design spec.

Automated resistance welding secures wire to support rods; rotation creates a cylindrical/conical screen.

CNC cutting, machining, and flanging bring dimensional accuracy up to ±0.1 mm.

Pickling, passivation, and surface roughness control. Slot size verified with laser gauges; mechanical stress tested (ISO/ANSI).

Custom head, flange, spine attach. 100% inspection for leakage, straightness, slot tolerance, etc.

Watch wedge wire basket manufacturing video

Technical Specifications and Parameter Table: Wedge Wire Basket (Centrifugal)

| Parameter | Industry Range | Centrifugal Basket (MutoScreen, 2024) | Standard/Cert. |

|---|---|---|---|

| Material | 304/316 stainless steel, Duplex 2205, Hastelloy, titanium | 316L, Duplex 2205, Super Duplex, Inconel | EN 10088, ASTM A240 |

| Slot Opening | 0.05 – 3 mm | 0.08 – 2 mm (customizable) | ISO 9001:2015, ANSI B16.5 |

| Basket Diameter | 250 – 1600 mm | 300, 400, 630, 800, 1000, 1120 mm | GB/T 15721-2012 |

| Basket Height | 200 – 1100 mm | 400, 600, 800, 1000 mm | ISO/FDIS 14291 |

| Open Area Ratio | 10 – 35% | 18 – 32% | Custom/ISO |

| Tolerance | ±1.0 mm | ±0.15 mm (critical slots) | EN 10204/3.1 |

| Surface Roughness (Ra) | Max 3.2 μm | < 1.3 μm | ISO 4287 / FDA |

| Service Life | 1 – 5 years | ≥3 years (avg.), up to 7 yrs in sugar industry | End-user record |

| Testing Standard | Hydraulic, mechanical, slot check, microstructure | Incl. leak, fatigue, hardness, slot/geometry laser test | ISO 9001, customer QA |

Comparing Leading Wedge Wire Basket Manufacturers (2024)

| Company | Main Market | Key Cert. | Max. Basket Size | Customization Level | Warranty |

|---|---|---|---|---|---|

| MutoScreen | Global (mining, sugar, wastewater) | ISO 9001, FDA, SGS | Ø1600 mm | 100% (size, slot, alloy, fitment) | 24 months |

| Andritz | Europe, Americas | ISO 9001, EHEDG | Ø1300 mm | Partial | 12-18 months |

| YUBO Filtration | APAC, Oil & Gas | ISO 14001, GB | Ø1200 mm | Partial | 12 months |

| Johnson Screens | Global | ISO 9001, API 6A | Ø1250 mm | Custom geometry, not alloy | 12-15 months |

Customization and OEM Solutions: MutoScreen Centrifugal Baskets

- Slot Range: 0.08 – 2.00 mm (accuracy ±0.015 mm)

- Diameters: 250 – 1600 mm; heights 200 – 1120 mm

- Alternative Alloys: Titanium, Inconel 625, Super Duplex, per process needs

- Custom Flange, Head, and Reinforcement: Engineering per client equipment; 2D/3D simulation pre-manufacture

- Design Validation: FEA (Finite Element Analysis) & CFD reports provided for mission-critical projects

- End Finishing: Polishing (up to Ra≤1.3 μm), anti-corrosion treatments

- Standards: Full documentation (MTRs, EN 10204/3.1) per ISO 9001, ANSI, GB, and customer QA requirements

Application Scenarios: Advantages and Real Cases

| Industry | Media/Process | Solution & Results |

|---|---|---|

| Sugar Processing | Molasses, fiber, crystals | Upgrade to Duplex wedge wire basket increased service from avg 1.8 → 5.2 years; reduced sugar loss by 17.4% |

| Mining | Coal slurry, phosphate ore | Centrifugal baskets with 0.4 mm slots improved particle retention; output up by 9%, maintenance interval doubled |

| Petrochemical | Resins, catalysts | Super Duplex baskets provided 2.5x corrosion lifecycle; flow rate +28%. Met ISO 9001 and FDA cleanability standards |

| Wastewater | Fine particles, grit removal | Customized slot geometry (0.15 mm) improved SS removal efficiency to 97.8% in client’s system (2023 case study) |

Key Advantages of Wedge Wire Basket Technology

- High Mechanical Strength: Withstand G-forces up to 4000G in modern centrifugal units

- Precise Slot Control: Laser gauge measured, essential for filtration uniformity and performance

- Plugging & Blinding Resistance: V-profile prevents clogging and ensures consistent throughput

- Chemical & Thermal Durability: Resistant to acids, alkalis, high temperatures up to 400°C, per selected alloy

- Easy Maintenance: Smooth inside/outside surfaces minimize media buildup, quick cleaning cycles

- Long Lifecycle: Reduced total cost of ownership — up to 3–5x vs perforated screens (user benchmark data)

FAQ & Professional Technical FAQ (Expert Insights)

Q1: What types of stainless steel are recommended for wedge wire basket in corrosive processes?

A: 316L, Duplex 2205, Super Duplex 2507 offer superior corrosion resistance; for high-chloride or acidic environments, consult alloy selection per NACE MR standards or request MutoScreen's alloy compatibility chart.

Q2: How is slot accuracy controlled and verified?

A: Slot openings are formed by CNC profile winding/welding, then measured via laser gauge (tolerance ±0.015 mm). Each screen batch is QA-verified per ISO 9001:2015 traceability.

Q3: What mounting or installation standards apply for centrifugal wedge wire screen basket?

A: Custom flanges, head, and spine are manufactured to ISO 14291 or customer-specific drawings; balanced per ISO 21940 (rotational balancing).

Q4: What is the typical open area percentage, and why does it matter?

A: Open area usually ranges 15–35%; higher open area improves permeability and capacity while maintaining strength. Choice depends on solids loading, media viscosity, and required particle cut-off.

Q5: How are wedge wire baskets tested before shipment?

A: Thorough inspection includes mechanical stress/load testing, slot gauge checks, hydraulic leak testing, and full visual/QC logs. Test certificates (EN 10204) provided.

Q6: Can baskets be supplied with FDA/food-grade documentation?

A: Yes. All MutoScreen baskets can meet FDA, EU EC1935/2004, and 3A Sanitary standards. Material traceability, passivation, and clean surface finish as required.

Q7: What is the typical delivery time for custom wedge wire basket orders?

A: Standard cycle is 15–28 days including QA. Urgent OEM spare orders can be fulfilled in under 7–12 days based on slot complexity and alloy availability; contact MutoScreen for an expedited quote.

Support, Delivery, and Warranty—Your Trust, Secured

- Warranty: All wedge wire basket products carry a minimum 24-month warranty against material and manufacturing defects.

- Customer Service: 24/7 technical hotline (contact info here), remote troubleshooting, field engineer visits on demand.

- QA Documentation: Provided for all orders: MTC, inspection reports, material trace, balancing & slot certificates.

- Post-Delivery: End-user training (onsite/online), annual health checks, O&M (operation & maintenance) support program available.

- Global Delivery: Air/sea/express delivery. Packaging per ISPM 15 and EN 12079.

Conclusion: Why Choose Centrifugal Baskets from MutoScreen?

- Proven 2–5x operational life improvement over mesh/perforated alternatives

- Verified performance backed by real-world customer data and global industry standards (ISO, ANSI, FDA, EHEDG)

- Engineering-driven customization, rapid lead times, and full post-sale guarantee

- Used by global leaders in sugar, mineral, chemical, and municipal sectors

— Process Manager, Indonesia’s Top 3 Sugar Producer (2023 Serum Industry Report)

References & Further Reading

- “Global Wedge Wire Basket Trends 2023–2026.” Statista Industry Markets

- “Filtration & Separation: The Wedgewire Screen Advantage.” Filtration+Separation Magazine

- ISO 9001:2015 Quality Management Systems. ISO.org Standards

- “Centrifugal Screens: Performance & Maintenance Benchmarks.” Sugar Industry Info Forums

- “Wedge Wire Technologies and Modern Manufacturing.” LinkedIn Engineering Pulse (2024)

- “Wedge Wire Basket Slot Sizing & Application.” MutoScreen Blog