Polyurethane Slot Screen Plate: Durable and Efficient Solution for Industrial Sieving

Muto Wire Screen Co., Ltd. (Anping Muto Metal Wire Mesh Products Co., Ltd.) is a leading manufacturer of high-quality polyurethane sieve plates, specializing in industrial sieving solutions. Our Polyurethane Slot Screen Plate is designed to meet the demanding requirements of various industries, offering exceptional durability and efficiency. This article explores the technical specifications, applications, and advantages of our product, along with insights into our company's commitment to innovation and customer satisfaction.

Understanding Polyurethane Slot Screen Plate

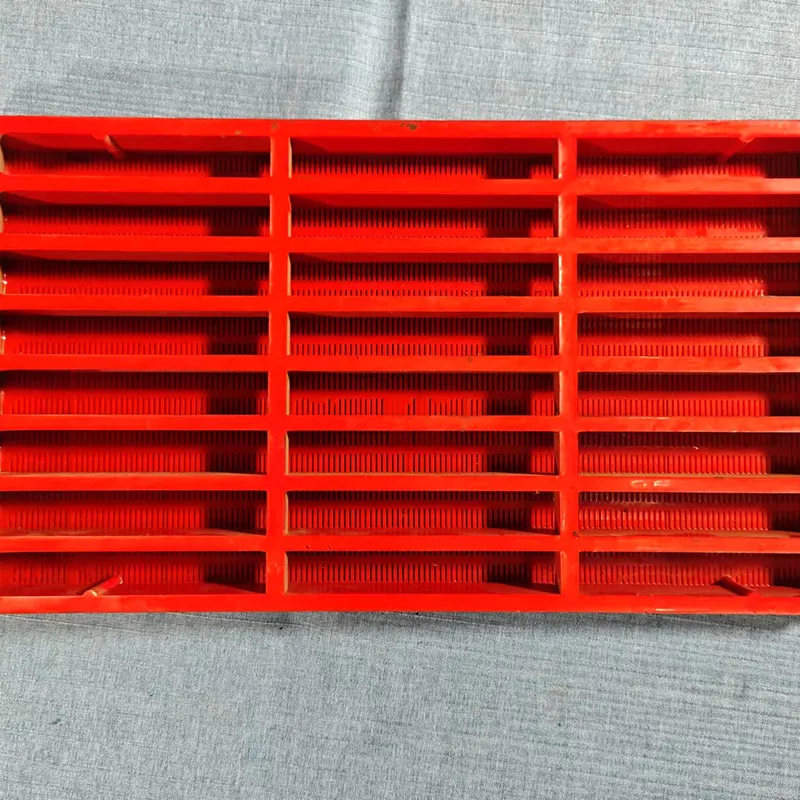

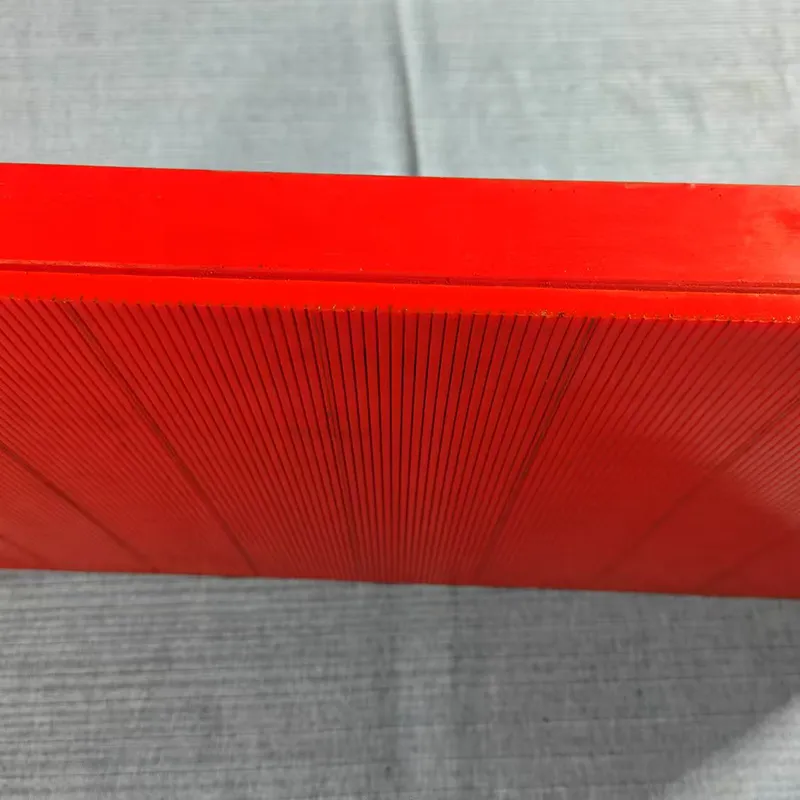

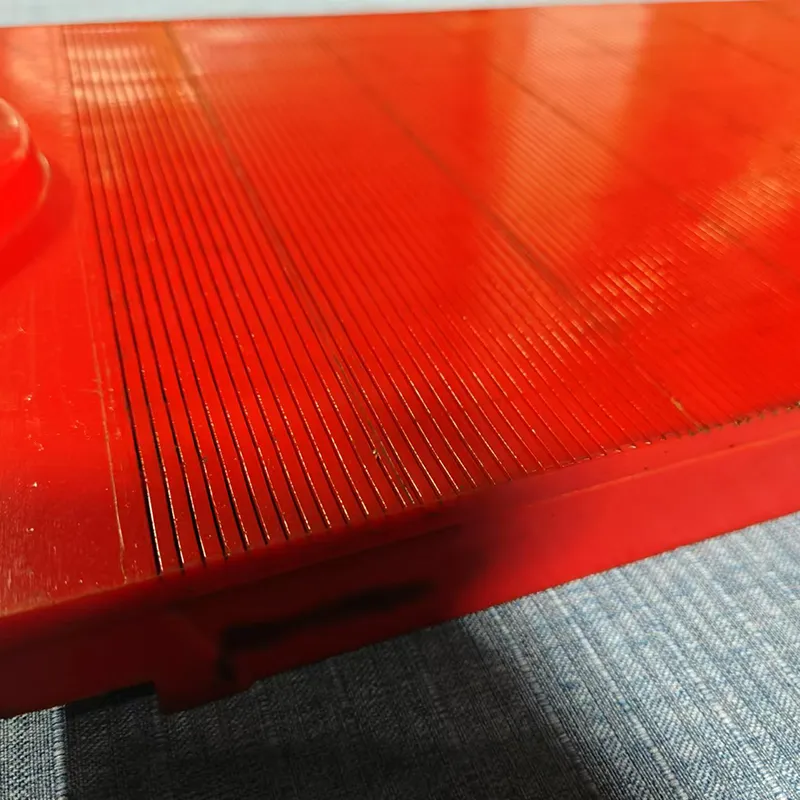

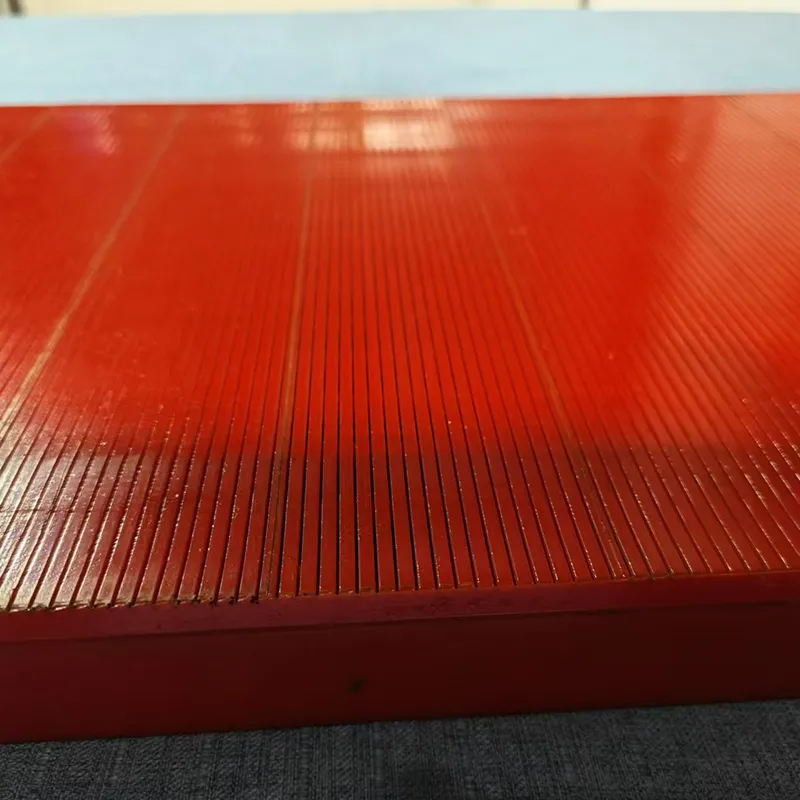

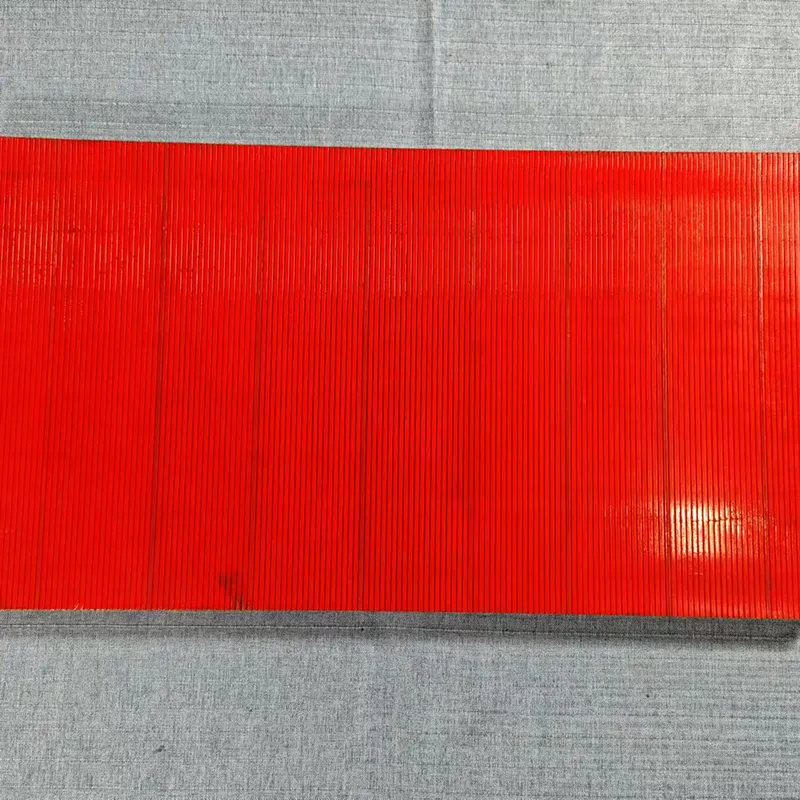

The Polyurethane Slot Screen Plate is a specialized screening component made from high-density polyurethane material. It is engineered to provide superior wear resistance, high tensile strength, and excellent flexibility, making it ideal for industrial sieving applications. The unique slot design allows for efficient separation of materials while minimizing clogging and wear. This product is particularly suited for environments where traditional metal screens may degrade quickly due to abrasive or corrosive conditions.

Technical Specifications

- Material: High-density polyurethane (PU)

- Surface Treatment: Anti-static and corrosion-resistant coating

- Thickness: 3-12 mm (customizable)

- Slot Size: 0.5-10 mm (varies by application)

- Load Capacity: 500-1000 kg/m²

- Operating Temperature Range: -30°C to +80°C

Key Advantages of Polyurethane Slot Screen Plate

1. Exceptional Durability

Compared to traditional metal screens, our Polyurethane Slot Screen Plate offers significantly longer service life. The high-density polyurethane material resists abrasion, impact, and chemical corrosion, reducing the need for frequent replacements. This translates to lower maintenance costs and downtime for industrial operations.

2. Enhanced Screening Efficiency

The precise slot design of the polyurethane screen plate ensures efficient separation of materials, even in high-volume applications. Its flexibility allows for better material flow, reducing clogging and improving throughput. This makes it ideal for industries such as mining, chemical processing, and food manufacturing, where consistent screening performance is critical.

3. Cost-Effective Solution

While the initial investment in polyurethane screen plates may be higher than traditional alternatives, the long-term cost savings are substantial. The reduced need for replacements and maintenance, combined with improved operational efficiency, provides a strong return on investment. For more details, visit our product page.

Industrial Applications of Polyurethane Slot Screen Plate

Our Polyurethane Slot Screen Plate is widely used across multiple industries, including:

- Mineral Processing: Efficient separation of ores and minerals in vibrating screens.

- Chemical Industry: Corrosion-resistant screening of chemical powders and granules.

- Food and Beverage: Hygienic and durable screening for food-grade materials.

- Construction: Separation of sand, gravel, and aggregates in concrete production.

- Recycling: Sorting of recyclable materials in waste processing facilities.

Addressing Industry Challenges with Polyurethane Technology

Traditional metal screens often face challenges such as wear, corrosion, and inefficiency in high-abrasion environments. The Polyurethane Slot Screen Plate effectively addresses these issues through its advanced material properties. For example, in the mining industry, our product can withstand the harsh conditions of ore screening, reducing downtime and maintenance costs. In the food industry, its non-porous surface prevents contamination, ensuring compliance with hygiene standards.

About Muto Wire Screen Co., Ltd.

Muto Wire Screen Co., Ltd. (Anping Muto Metal Wire Mesh Products Co., Ltd.) has been a trusted name in the wire mesh and screen industry for over a decade. With a focus on innovation and quality, we specialize in manufacturing polyurethane sieve plates, dewatering screens, and other industrial screening solutions. Our state-of-the-art production facilities and rigorous quality control processes ensure that every product meets the highest standards of performance and reliability.

Our Technological Advancements

At Muto Wire Screen Co., Ltd., we invest heavily in research and development to stay at the forefront of screening technology. Our team of engineers continuously improves the design and material composition of our Polyurethane Slot Screen Plate to meet evolving industry needs. We also collaborate with leading manufacturers to integrate the latest advancements in polyurethane technology, ensuring our products deliver superior performance and longevity.

Proven Performance and Customer Testimonials

Our Polyurethane Slot Screen Plate has been successfully deployed in numerous industrial applications, earning praise from customers worldwide. Here are some testimonials from our clients:

"The polyurethane screens from Muto Wire Screen Co., Ltd. have significantly reduced our maintenance costs and improved the efficiency of our mineral processing operations. Highly recommended!"

- John D., Mining Industry Manager

"As a food processing company, we rely on the hygienic and durable performance of Muto's screens. They have become an essential part of our production line."

- Sarah L., Quality Assurance Director

Implementation and Customization Options

We understand that each industrial application has unique requirements. That's why we offer tailored solutions for our Polyurethane Slot Screen Plate. Our team works closely with clients to determine the optimal slot size, thickness, and material composition for their specific needs. Whether you require a standard configuration or a custom design, we ensure seamless integration into your existing equipment.

Installation and Maintenance Guide

Proper installation and maintenance are crucial for maximizing the performance of our Polyurethane Slot Screen Plate. Follow these guidelines to ensure long-term reliability:

- Ensure the screening equipment is clean and free of debris before installation.

- Secure the screen plate using the recommended fastening methods to prevent misalignment.

- Regularly inspect the screen for signs of wear and replace as needed.

- Clean the surface with a mild detergent to maintain optimal screening efficiency.

Environmental and Safety Compliance

Muto Wire Screen Co., Ltd. is committed to producing Polyurethane Slot Screen Plate that meets international environmental and safety standards. Our products are manufactured using eco-friendly materials and processes, minimizing their carbon footprint. Additionally, the non-toxic nature of polyurethane ensures safe handling and operation in sensitive environments.

Packaging and Shipping Solutions

We provide customized packaging options to ensure the safe transportation of our Polyurethane Slot Screen Plate to your facility. Our packaging is designed to protect the product from damage during transit, regardless of the shipment size. For bulk orders, we offer cost-effective shipping solutions tailored to your logistics requirements. Contact us for detailed shipping information.

Comprehensive Customer Support

At Muto Wire Screen Co., Ltd., we prioritize customer satisfaction. Our dedicated support team is available to provide technical guidance, answer product inquiries, and assist with custom orders. We also offer on-site training and maintenance services to ensure our Polyurethane Slot Screen Plate operates at peak performance. For further assistance, please visit our company website.

Conclusion

The Polyurethane Slot Screen Plate from Muto Wire Screen Co., Ltd. is a reliable and cost-effective solution for industrial sieving needs. With its advanced material properties, efficient design, and customizable options, it offers unmatched performance in demanding environments. Discover how our product can enhance your operations today.

Frequently Asked Questions

Q1: What are the main advantages of using polyurethane screens over traditional metal screens?

A: Polyurethane screens offer superior wear resistance, flexibility, and chemical resistance compared to metal screens. They also reduce maintenance costs and improve screening efficiency due to their unique material properties.

Q2: Can the Polyurethane Slot Screen Plate be customized for specific applications?

A: Yes, we offer custom solutions for slot size, thickness, and material composition to meet the unique requirements of different industries.

Q3: How long does the Polyurethane Slot Screen Plate last in harsh environments?

A: The service life of our screens depends on the application, but they typically last 3-5 times longer than traditional metal screens due to their exceptional durability.

Q4: Are your products environmentally friendly?

A: Yes, our polyurethane screens are made from eco-friendly materials and are designed to minimize environmental impact throughout their lifecycle.

Q5: What support do you provide after purchasing the product?

A: We offer technical support, maintenance guidance, and on-site services to ensure optimal performance of our Polyurethane Slot Screen Plate.

Visit Muto Wire Screen Co., Ltd. to learn more about our products and services.