Wedge Wire Screen - Muto Wire Screen Co., Ltd.|Industrial Sieving,Filtration Technology,Customizable Solutions

Wedge Wire Screen: Advanced Solutions for Industrial Sieving and Filtration

Wedge Wire Screen, a cutting-edge screening solution developed by Muto Wire Screen Co., Ltd., is revolutionizing the way industries approach sieving and filtration. This innovative product combines precision engineering with durable materials to deliver exceptional performance in demanding applications. Whether you're in mining, chemical processing, or food manufacturing, our Wedge Wire Screen offers a reliable and efficient solution to meet your specific needs. Explore how this advanced technology can enhance your production processes and drive operational excellence.

Understanding Wedge Wire Screen Technology

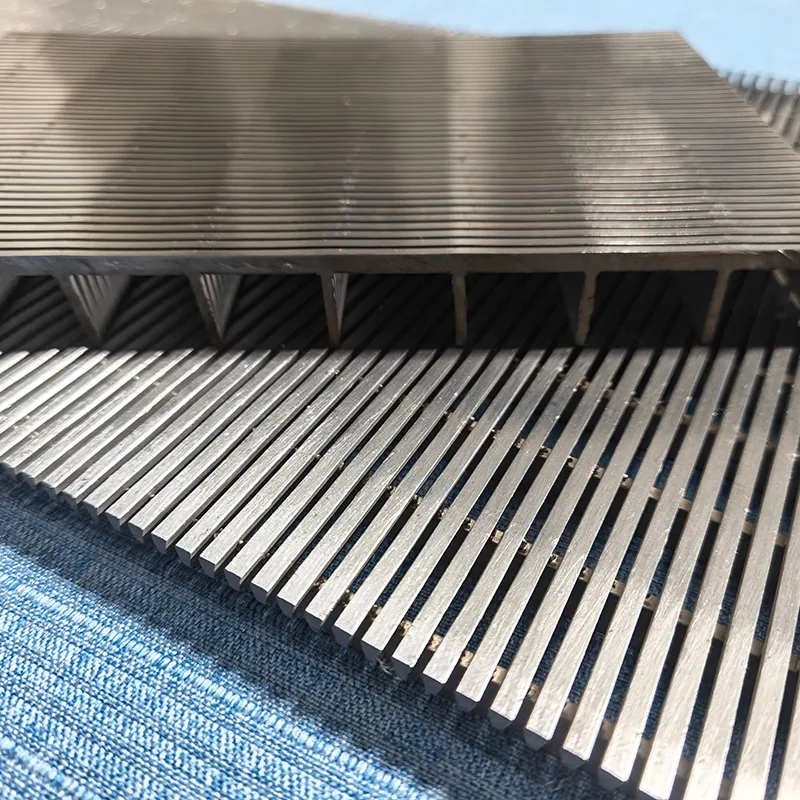

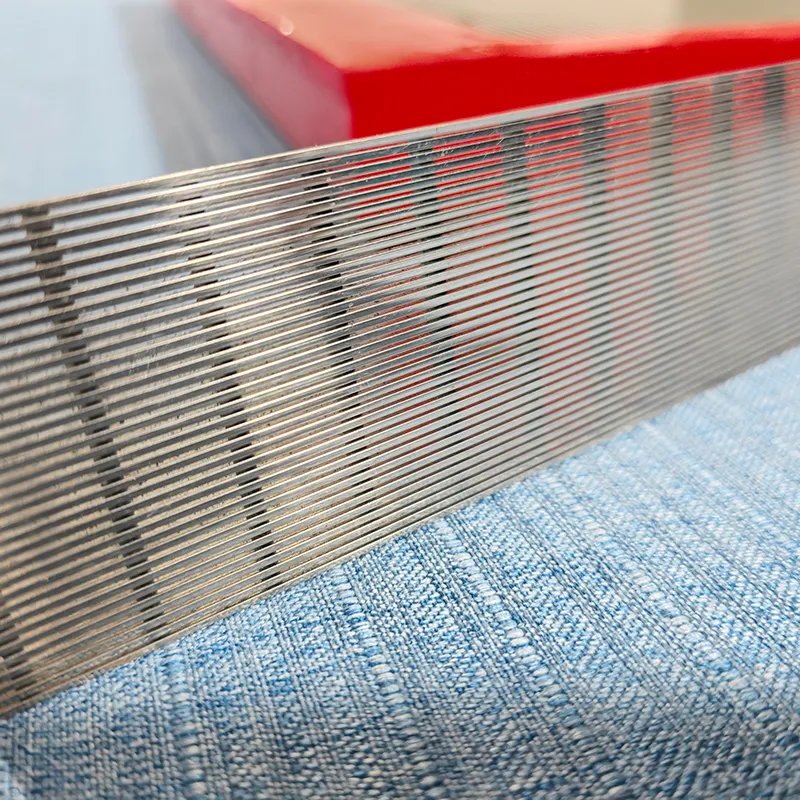

Wedge Wire Screen is a specialized type of wire mesh characterized by its unique design. Unlike traditional woven wire screens, which have a square or rectangular weave pattern, Wedge Wire Screens feature a triangular cross-section wire arranged in a precise, parallel configuration. This design creates a series of evenly spaced slots that allow for precise particle separation while maintaining structural integrity.

The key components of a Wedge Wire Screen include:

- Wedge-shaped wires: These wires have a triangular cross-section that forms the screening surface.

- Supporting rods: Perpendicular rods provide structural support and maintain the alignment of the wedge wires.

- Frame: A sturdy frame holds the entire structure together, ensuring durability in industrial environments.

This innovative design offers several advantages over conventional screening solutions, including increased open area, reduced clogging, and enhanced durability. The parallel arrangement of the wedge wires creates a more uniform flow path, which improves screening efficiency and extends the service life of the screen.

Industrial Applications of Wedge Wire Screen

Wedge Wire Screen is widely used across various industries due to its exceptional performance characteristics. Some of the most common applications include:

- Mineral Processing: Used in screening and classification of ores, sands, and other particulate materials.

- Chemical Industry: Employed for separating fine powders and granules in chemical manufacturing processes.

- Food Processing: Ideal for screening ingredients in the production of flour, sugar, and other food products.

- Pharmaceuticals: Ensures precise particle size control in drug manufacturing.

- Waste Management: Used for sorting and separating different types of waste materials.

The versatility of Wedge Wire Screen makes it an essential component in many industrial operations. Its ability to handle high-volume throughput while maintaining accurate particle separation makes it a preferred choice for manufacturers seeking to optimize their production processes.

Key Advantages of Wedge Wire Screen

Compared to traditional screening solutions, Wedge Wire Screen offers several distinct advantages that make it a superior choice for industrial applications:

- Enhanced Screening Efficiency: The unique design of Wedge Wire Screen allows for a higher open area, which improves the throughput capacity and reduces the risk of clogging.

- Increased Durability: Constructed from high-quality materials, these screens can withstand harsh operating conditions and maintain their performance over extended periods.

- Precision Particle Separation: The uniform slot size and parallel wire arrangement ensure consistent particle size control, which is crucial for many industrial processes.

- Easy Maintenance: The robust design of Wedge Wire Screen minimizes the need for frequent maintenance and replacement, reducing downtime and operational costs.

- Customization Options: These screens can be tailored to meet specific application requirements, including different slot sizes, wire diameters, and frame configurations.

These advantages make Wedge Wire Screen an ideal solution for industries that require reliable and efficient screening performance. By investing in this advanced technology, manufacturers can achieve significant improvements in productivity and cost-effectiveness.

Addressing Industry Challenges with Wedge Wire Screen

The industrial screening and filtration market faces several challenges that can impact operational efficiency and product quality. Traditional screening solutions often struggle with issues such as:

- Clogging and blockage: Conventional wire mesh screens can become clogged with fine particles, leading to reduced throughput and increased maintenance requirements.

- Wear and tear: The constant exposure to abrasive materials can cause rapid degradation of screening surfaces, resulting in frequent replacements.

- Inconsistent particle separation: Variations in wire spacing and mesh construction can lead to uneven particle size distribution, affecting product quality.

- High operational costs: Inefficient screening systems can increase energy consumption and reduce overall production efficiency.

Wedge Wire Screen is specifically designed to address these challenges. The unique triangular cross-section of the wires and the parallel arrangement of the slots create a more efficient flow path that minimizes clogging. The durable construction ensures long-term performance in abrasive environments, while the precise manufacturing process guarantees consistent particle separation. By implementing Wedge Wire Screen, industries can achieve significant improvements in operational efficiency and cost savings.

About Muto Wire Screen Co., Ltd.

Muto Wire Screen Co., Ltd. is a leading manufacturer of high-quality wire mesh products, specializing in the production of Wedge Wire Screen and other advanced screening solutions. With over [X] years of experience in the industry, our company has established itself as a trusted provider of reliable and innovative products for industrial applications.

Our commitment to quality and customer satisfaction has enabled us to serve a diverse range of clients across various industries. We combine cutting-edge technology with meticulous craftsmanship to produce wire mesh products that meet the highest standards of performance and durability. Whether you need a standard screening solution or a custom-designed product, our team of experts is dedicated to providing tailored solutions that meet your specific requirements.

At Muto Wire Screen Co., Ltd., we continuously invest in research and development to stay at the forefront of technological advancements in the wire mesh industry. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every product we produce meets the strictest industry standards. By choosing our Wedge Wire Screen, you can be confident that you're getting a high-quality solution that delivers exceptional performance and long-term value.

Technical Specifications of Wedge Wire Screen

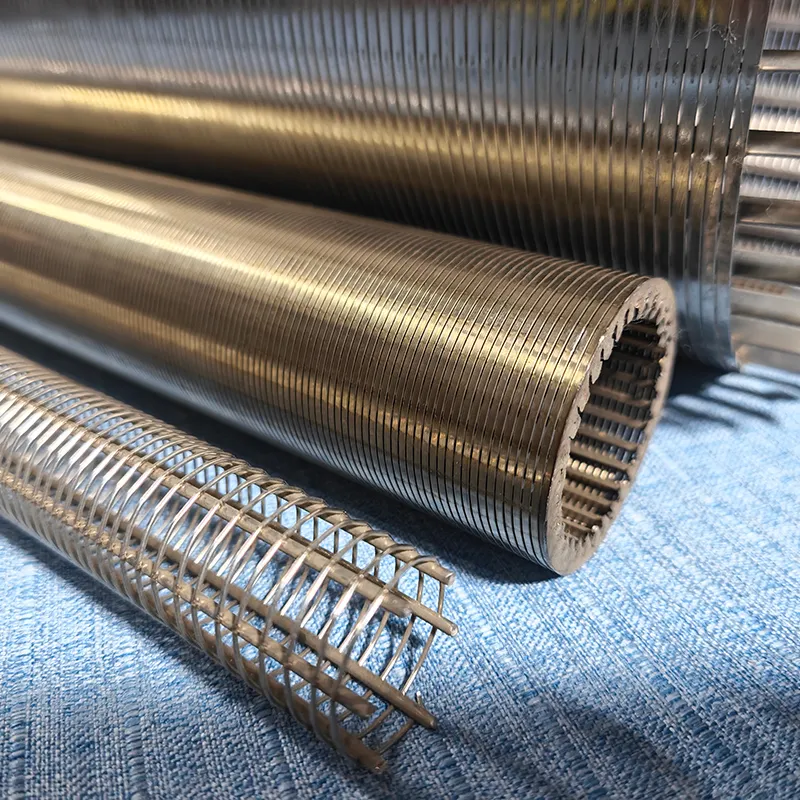

Wedge Wire Screen is available in a wide range of specifications to suit different industrial applications. Some of the key technical parameters include:

| Parameter | Specification |

|---|---|

| Wire Material | Stainless steel (304, 316), carbon steel, or other custom alloys |

| Wire Diameter | 0.5mm - 5.0mm (customizable) |

| Slot Size | 0.1mm - 10mm (customizable) |

| Screen Length | Up to 3000mm (customizable) |

| Screen Width | Up to 2000mm (customizable) |

| Frame Material | Stainless steel, carbon steel, or aluminum |

These specifications can be customized to meet the specific requirements of different applications. Our team of engineers works closely with clients to design and manufacture Wedge Wire Screens that deliver optimal performance for their unique needs.

Implementing Wedge Wire Screen in Your Operations

Integrating Wedge Wire Screen into your industrial processes can significantly enhance your screening and filtration capabilities. Here's a step-by-step guide to help you implement this advanced technology:

- Assess Your Needs: Evaluate your current screening requirements and identify areas where Wedge Wire Screen can provide the most value.

- Consult with Experts: Contact our team of specialists to discuss your specific application and determine the optimal configuration for your needs.

- Custom Design: Work with our engineers to develop a customized solution that meets your unique requirements.

- Installation: Our technicians can provide guidance on proper installation and integration into your existing systems.

- Training: Receive comprehensive training on the operation and maintenance of your Wedge Wire Screen to ensure optimal performance.

- Monitoring and Optimization: Regularly monitor the performance of your screening system and make adjustments as needed to maintain efficiency.

By following these steps, you can seamlessly integrate Wedge Wire Screen into your operations and start reaping the benefits of this advanced technology.

Ensuring Safety and Compliance

At Muto Wire Screen Co., Ltd., we prioritize safety and compliance in all our products. Our Wedge Wire Screen is manufactured to meet the highest industry standards, ensuring that it is safe for use in various industrial environments. Key safety features include:

- Durable Construction: The robust design of our screens ensures they can withstand harsh operating conditions without compromising safety.

- Non-Toxic Materials: We use high-quality, non-toxic materials that are safe for use in food processing and other sensitive applications.

- Compliance with Standards: Our products meet international standards for industrial safety and quality, including ISO certifications.

- Easy Maintenance: The design of our screens allows for easy cleaning and maintenance, reducing the risk of contamination and ensuring a safe working environment.

By choosing our Wedge Wire Screen, you can be confident that you're getting a product that not only delivers exceptional performance but also prioritizes the safety of your workforce and the integrity of your operations.

Packaging and Delivery Solutions

We understand that efficient packaging and reliable delivery are crucial for industrial customers. Our Wedge Wire Screen is packaged to ensure safe transportation and easy handling:

- Durable Packaging: Each screen is carefully packaged in sturdy containers to protect it during transit.

- Customizable Options: We offer various packaging solutions to accommodate different order sizes and transportation requirements.

- Global Logistics: Our extensive network of logistics partners ensures timely delivery to customers around the world.

- Tracking Services: We provide real-time tracking information so you can monitor the status of your shipment at all times.

Our goal is to make the procurement and delivery process as seamless as possible for our customers. Whether you need a small batch or a large-volume order, we have the resources and expertise to ensure your Wedge Wire Screen arrives in perfect condition.

Comprehensive Customer Support

We are committed to providing exceptional customer support to ensure your success with our Wedge Wire Screen. Our dedicated support team is available to assist with:

- Technical Consultation: Our experts can help you select the right product configuration for your specific application.

- Product Training: We offer comprehensive training programs to ensure you get the most out of your screening system.

- After-Sales Service: Our technicians are available to provide maintenance and repair services as needed.

- Custom Solutions: We work closely with clients to develop tailored solutions that meet their unique requirements.

At Muto Wire Screen Co., Ltd., we believe that customer satisfaction is our top priority. Our team is dedicated to providing timely and effective support to ensure that you achieve the best possible results with our products.

How to Get Started with Wedge Wire Screen

Ready to experience the benefits of Wedge Wire Screen? Follow these simple steps to get started:

- Contact Us: Reach out to our sales team through our website or by phone to discuss your requirements.

- Request a Quote: Provide detailed specifications for your application to receive a customized quotation.

- Place Your Order: Once you've reviewed the quotation, proceed with placing your order.

- Receive Your Product: Our logistics team will ensure your Wedge Wire Screen is delivered efficiently and safely.

- Enjoy the Benefits: Start reaping the advantages of our advanced screening solution in your operations.

By choosing Muto Wire Screen Co., Ltd., you're not just purchasing a product - you're investing in a partnership that will help you achieve greater efficiency and productivity in your industrial operations.

Frequently Asked Questions (FAQ)

What materials are used in the production of Wedge Wire Screen?

Wedge Wire Screen is typically made from high-quality stainless steel (304, 316), carbon steel, or other custom alloys depending on the specific application requirements.

Can Wedge Wire Screen be customized for different applications?

Yes, we offer customizable solutions to meet the unique requirements of different industries and applications. Our engineers can design screens with specific slot sizes, wire diameters, and frame configurations.

What is the typical lead time for orders?

The lead time for orders may vary depending on the complexity of the product and the volume of the order. Our team will provide a detailed timeline once your specifications are confirmed.

Do you offer installation support?

Yes, we provide guidance and support for the installation of our Wedge Wire Screen. Our technicians can assist with the integration of the product into your existing systems.

What is the warranty period for your products?

We offer a comprehensive warranty on all our products, ensuring that you receive a reliable and durable solution. The specific warranty terms will be provided with your quotation.

Conclusion

Wedge Wire Screen from Muto Wire Screen Co., Ltd. offers a superior solution for industrial sieving and filtration needs. With its advanced design, exceptional durability, and customizable options, this product is ideal for a wide range of applications. By choosing our Wedge Wire Screen, you can enhance your production processes, reduce operational costs, and achieve greater efficiency. Discover the benefits of this innovative technology and experience the difference it can make in your operations. Learn more about our Wedge Wire Screen solutions today.