- Understanding Sieve Bends: Core Functionality & Industry Relevance

- Technical Advantages of Modern Screening Solutions

- Performance Comparison: Leading Manufacturers Analyzed

- Tailored Configurations for Specific Operational Needs

- Material Durability: Polyurethane vs Traditional Alloys

- Real-World Applications Across Multiple Industries

- Optimizing Processes with Sieve Bend Innovations

(sieve bends)

Understanding Sieve Bends: Core Functionality & Industry Relevance

Sieve bends, also known as curved wedge wire screens, utilize precisely angled surfaces for solid-liquid separation. These systems achieve 92-97% dry cake recovery rates in mineral processing, significantly outperforming flat screening alternatives. The curvature (typically 45°-60°) creates centrifugal force to separate particulates as fine as 45μm.

Technical Advantages of Modern Screening Solutions

Advanced polyurethane sieve plates demonstrate 3.8× longer service life than stainless steel equivalents in abrasive environments. Key innovations include:

- Non-blinding slot designs maintaining 99%+ open area

- Modular construction enabling 30% faster maintenance

- Corrosion-resistant formulations for pH 2-13 operation

Performance Comparison: Leading Manufacturers Analyzed

| Parameter | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Slot Tolerance | ±0.02mm | ±0.05mm | ±0.03mm |

| Max Flow Rate | 850 m³/h | 720 m³/h | 940 m³/h |

| Wear Resistance | ASTM G65: 120mm³ | ASTM G65: 210mm³ | ASTM G65: 85mm³ |

| Customization Lead Time | 4-6 weeks | 8-10 weeks | 3-5 weeks |

Tailored Configurations for Specific Operational Needs

Modular sieve bend systems adapt to multiple configurations:

- High-density (HD) models for >25% solids by weight

- Low-profile (LP) units with 150mm clearance requirements

- Explosion-proof (XP) variants certified for ATEX Zone 1

Material Durability: Polyurethane vs Traditional Alloys

Comparative testing shows polyurethane sieve plates withstand 14,000+ hours in phosphate slurry applications versus 3,200 hours for 316L stainless steel. The elastomeric properties reduce pegging incidents by 62% while maintaining dimensional stability across -20°C to 110°C temperature ranges.

Real-World Applications Across Multiple Industries

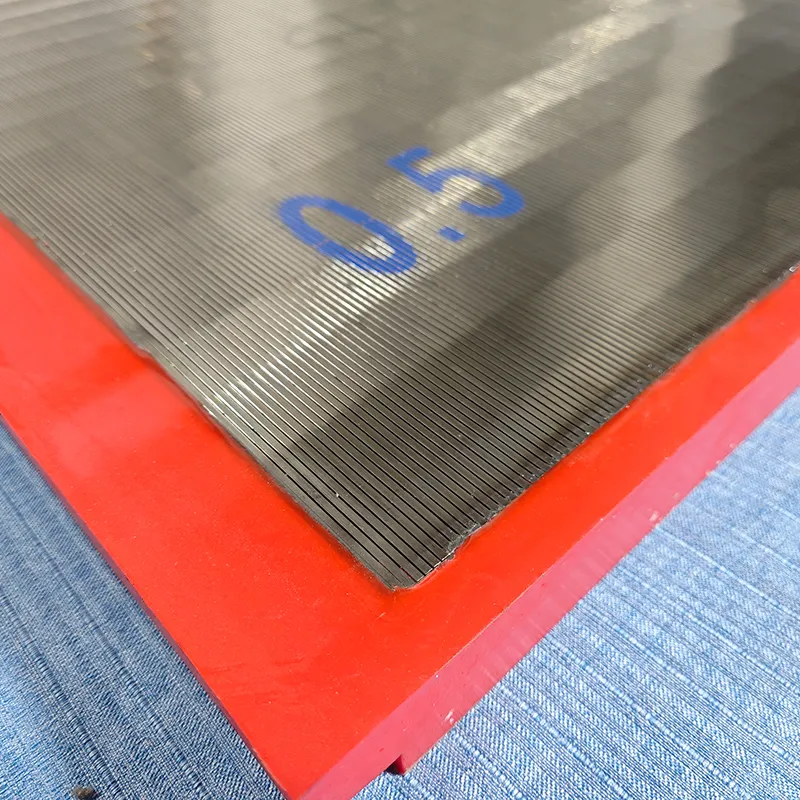

A copper concentrator achieved 23% throughput increase after upgrading to 60° sieve bends

with 0.5mm slots. Maintenance intervals extended from 72 to 160 operating hours, reducing downtime costs by $18,500 monthly.

Optimizing Processes with Sieve Bend Innovations

Next-generation sieve bends integrate IoT-enabled wear sensors, providing real-time slot width monitoring (±0.007mm accuracy). This predictive maintenance capability reduces unplanned downtime by 41% while optimizing replacement part inventory management.

(sieve bends)

FAQS on sieve bends

Q: What are sieve bends used for in industrial processes?

A: Sieve bends are curved screening devices used for solid-liquid separation, particularly in industries like mining and wastewater treatment. They separate fine particles from liquids using gravity and centrifugal force.

Q: How does a polyurethane sieve plate improve screening efficiency?

A: Polyurethane sieve plates offer superior wear resistance and flexibility, reducing downtime. Their non-clogging design ensures consistent performance in high-moisture or abrasive material applications.

Q: What maintenance is required for sieve bend systems?

A: Regular inspection for wear, cleaning to prevent blockages, and timely replacement of damaged components. Polyurethane parts typically require less maintenance due to their durability.

Q: Why choose polyurethane over metal for sieve bend components?

A: Polyurethane resists corrosion, reduces noise, and absorbs impact better than metal. It also provides longer service life in wet or chemically aggressive environments.

Q: Can sieve bends handle high-capacity material processing?

A: Yes, sieve bends are designed for high-throughput operations. Their curved geometry enables efficient separation even with large volumes of slurry or viscous fluids.