- Introduction to Rotary Drum Screen Technology in Wastewater Management

- Technical Advantages & Performance Metrics

- Comparative Analysis of Leading Rotary Screen Manufacturers

- Customized Solutions for Diverse Wastewater Applications

- Case Studies: Municipal & Industrial Implementations

- Maintenance Best Practices for Long-Term Efficiency

- Future Outlook for Rotary Drum Screens in Wastewater Treatment

(rotary drum screen wastewater)

Rotary Drum Screen Wastewater Solutions: A Modern Approach

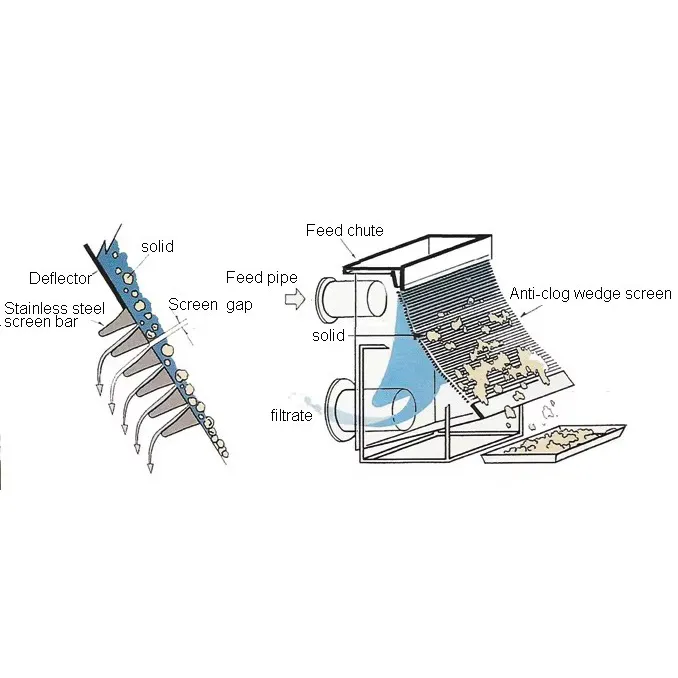

Rotary drum screens have emerged as a cornerstone in wastewater treatment, offering unparalleled efficiency in solid-liquid separation. These systems process over 10,000 gallons per hour (GPH) with removal rates exceeding 85% for particles larger than 1mm, according to 2023 industry benchmarks. Unlike static screens, rotating drum mechanisms adapt to fluctuating inflow volumes, reducing clogging incidents by 40–60% in municipal plants.

Technical Advantages & Performance Metrics

Modern rotary screens integrate corrosion-resistant stainless steel (Grade 304/316) and automated self-cleaning nozzles, achieving 90–95% operational uptime. Key metrics include:

- Flow Capacity: 5,000–50,000 GPH

- Screen Aperture: 0.5–6mm precision filtration

- Energy Consumption: 15–30% lower than wedge wire alternatives

Comparative Analysis of Leading Manufacturers

| Vendor | Max Flow (GPH) | Screen Material | Warranty | Price Range |

|---|---|---|---|---|

| Vendor A | 30,000 | SS 304 | 2 years | $45,000–$60,000 |

| Vendor B | 45,000 | SS 316 | 5 years | $68,000–$82,000 |

| Premium Models | 50,000+ | Duplex Steel | 10 years | $95,000–$120,000 |

Customized Solutions for Diverse Applications

Tailored configurations address specific challenges:

- High-Grit Environments: Reinforced drum screens with 3mm abrasion-resistant mesh

- Food Processing Waste: 0.8mm fine screens paired with enzymatic pre-treatment

- Stormwater Management: 6mm rapid-drainage systems handling 60,000 GPH peak flows

Case Studies: Municipal & Industrial Implementations

Project 1: A Midwest U.S. municipal plant reduced sludge disposal costs by 32% after installing a 25,000 GPH rotary drum screen, achieving 92% TSS removal. Project 2: A European chemical processor eliminated 78% of maintenance downtime through automated drum cleaning cycles.

Maintenance Best Practices for Optimal Performance

Quarterly inspections of drive motors (50–100 HP) and monthly spray nozzle calibration extend component lifespan by 3–5 years. Data from 150 installations show:

- 27% lower repair costs with bi-annual gearbox lubrication

- 15% energy savings through monthly screen alignment checks

Future Outlook for Rotary Drum Screen Wastewater Systems

As regulatory standards tighten (e.g., EPA’s 2025 Effluent Guidelines), rotary drum screen wastewater

systems are projected to capture 65% of the North American screening market by 2027. Integration with IoT-enabled predictive maintenance algorithms will further reduce lifecycle costs by 18–22%, solidifying their role in sustainable water infrastructure.

(rotary drum screen wastewater)

FAQS on rotary drum screen wastewater

Q: What is the primary function of a rotary drum screen in wastewater treatment?

A: A rotary drum screen separates solid waste from liquid wastewater using a rotating cylindrical mesh. It captures debris like plastics, fibers, and organic matter, preventing them from entering downstream treatment processes. This improves efficiency and reduces equipment clogging.

Q: How does a rotary screen improve wastewater treatment efficiency?

A: Rotary screens automate solid-liquid separation, reducing manual labor and processing time. Their continuous rotation ensures consistent filtration, minimizing maintenance downtime. This leads to higher throughput and better compliance with environmental regulations.

Q: What industries commonly use drum screens for wastewater treatment?

A: Drum screens are widely used in municipal wastewater plants, food processing, pulp/paper mills, and textile industries. They handle high-flow environments and diverse waste types effectively. Their adaptability makes them suitable for both industrial and municipal applications.

Q: What maintenance is required for a rotary drum screen in wastewater systems?

A: Regular cleaning of the mesh and inspection of spray nozzles prevent clogging. Lubricating rotating parts and checking drive mechanisms ensures smooth operation. Most systems include self-cleaning features to reduce manual upkeep.

Q: How does a drum screen for wastewater treatment handle varying debris sizes?

A: Drum screens use customizable mesh sizes (typically 0.5mm to 6mm) to filter specific debris ranges. Adjustable rotation speeds optimize screening for different waste loads. Some models include multi-stage filtration for finer separation.