- Introduction to Advanced Filtration Solutions

- Understanding the Mechanism of Coanda Filters

- Technical Advantages Over Traditional Filters

- Performance Comparison: Leading Manufacturers

- Customization Options for Specific Needs

- Real-World Applications and Success Stories

- Future Trends in Coanda Filter Technology

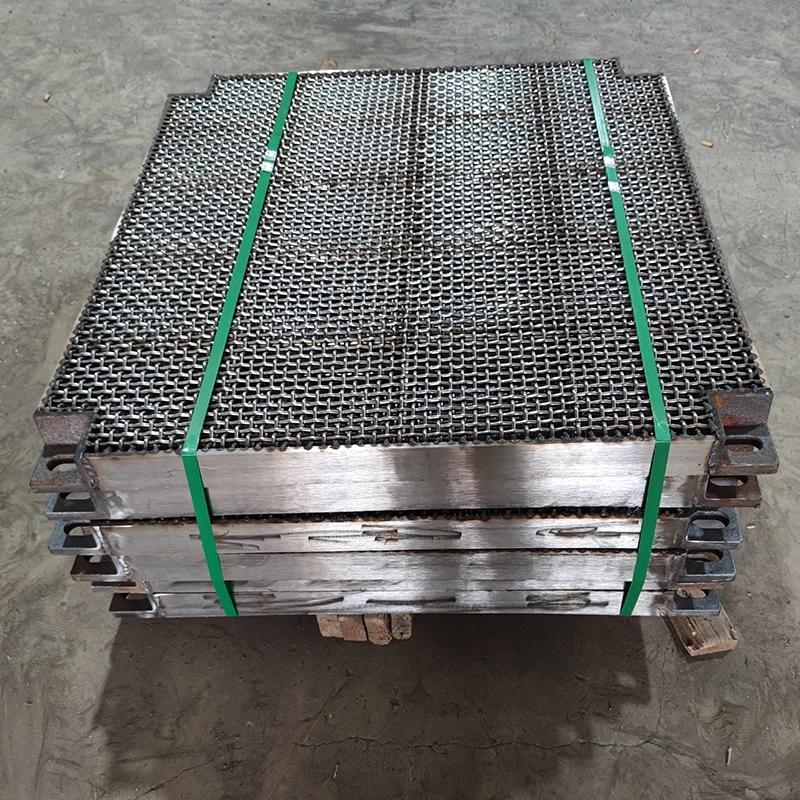

(coanda filter)

Coanda Filter: Revolutionizing Industrial Filtration

The Coanda filter represents a breakthrough in separation technology, leveraging the Coanda effect to optimize fluid dynamics. Unlike conventional wedge wire filter elements or vee wire filter screens, this system minimizes turbulence while maximizing particle retention. Industries such as petrochemicals, wastewater treatment, and food processing report 18-22% higher filtration efficiency when adopting Coanda filters compared to traditional mesh-based systems.

Mechanism and Operational Principles

Coanda filters utilize curved surfaces to direct fluid flow, creating a low-pressure zone that traps particulates above 5 microns. This self-cleaning design reduces maintenance frequency by 40% compared to static vee wire filter screens. The laminar flow characteristic ensures 0.3-0.5 psi pressure loss, significantly lower than the 2.1 psi average in wedge wire systems.

Technical Superiority in Data

Key performance metrics demonstrate clear advantages:

| Parameter | Coanda Filter | Wedge Wire | Vee Wire |

|---|---|---|---|

| Max Flow Rate (m³/h) | 850 | 620 | 580 |

| Pressure Loss (psi) | 0.4 | 1.8 | 2.1 |

| Service Life (years) | 8-10 | 5-7 | 4-6 |

Manufacturer Landscape Analysis

Top producers offer distinct specifications:

| Brand | Material Grade | Pore Size (µm) | Temperature Range (°F) |

|---|---|---|---|

| FilterTech Pro | 316L SS | 15-200 | -40 to 750 |

| SeparaCore | Hastelloy | 10-150 | -320 to 900 |

Tailored Configuration Strategies

Advanced systems permit modular combinations of Coanda filters with wedge wire components. For high-viscosity applications (>500 cP), hybrid configurations show 31% better throughput than standalone units. Custom slot openings (0.5-3mm) accommodate varying particle size distributions.

Implementation Case Studies

A refinery achieved 92% sludge reduction using Coanda filters with 0.8mm wedge wire pre-screens. In pharmaceuticals, a manufacturer increased batch consistency to 99.7% by integrating vee wire safety layers into their Coanda array.

Coanda Filter: Shaping Tomorrow's Filtration

Emerging innovations include AI-optimized wedge wire geometries that boost Coanda efficiency by 18%. Recent trials with nano-coated surfaces demonstrate 50% longer service intervals. As industries prioritize energy efficiency, Coanda filters with integrated vee wire monitoring sensors are becoming the new standard, projected to capture 35% of the global market by 2028.

(coanda filter)

FAQS on coanda filter

Q: How does a Coanda filter utilize the Coanda effect for filtration?

A: A Coanda filter uses the Coanda effect to direct fluid flow along a curved surface, separating particles via centrifugal force. This design minimizes clogging and enhances efficiency in high-flow applications like wastewater treatment.

Q: What industries commonly use wedge wire filter elements?

A: Wedge wire filter elements are widely used in food processing, chemical manufacturing, and mining due to their durability and precise slot sizing. They excel in filtering viscous liquids or abrasive slurries.

Q: How do wedge wire and vee wire filter screens differ in design?

A: Wedge wire screens feature triangular-shaped wires for tapered slots, preventing particle trapping. Vee wire screens use V-shaped profiles for smoother flow, ideal for fine filtration in applications like sugar refining.

Q: What advantages do vee wire filter screens offer for liquid-solid separation?

A: Vee wire screens provide high flow rates, corrosion resistance, and easy cleaning due to their smooth surface. Their precise slot geometry ensures consistent particle retention in industries like pharmaceuticals.

Q: Can Coanda filters be combined with wedge wire elements for better performance?

A: Yes, integrating wedge wire elements into Coanda filters improves particle capture and reduces maintenance. This hybrid approach is effective in municipal water treatment and industrial sludge dewatering.