- Understanding the Role of Flip Flop Screens in Coal Processing

- Technical Advantages of Modern Vibrating Screens

- Performance Comparison: Leading Manufacturers in the Market

- Custom Solutions for Diverse Coal Screening Needs

- Case Study: Efficiency Gains in a Coal Processing Plant

- Maintenance Strategies for Long-Term Reliability

- Future Trends in Flip Flop Screen Technology

(flip flop screen for coal)

Understanding the Role of Flip Flop Screens in Coal Processing

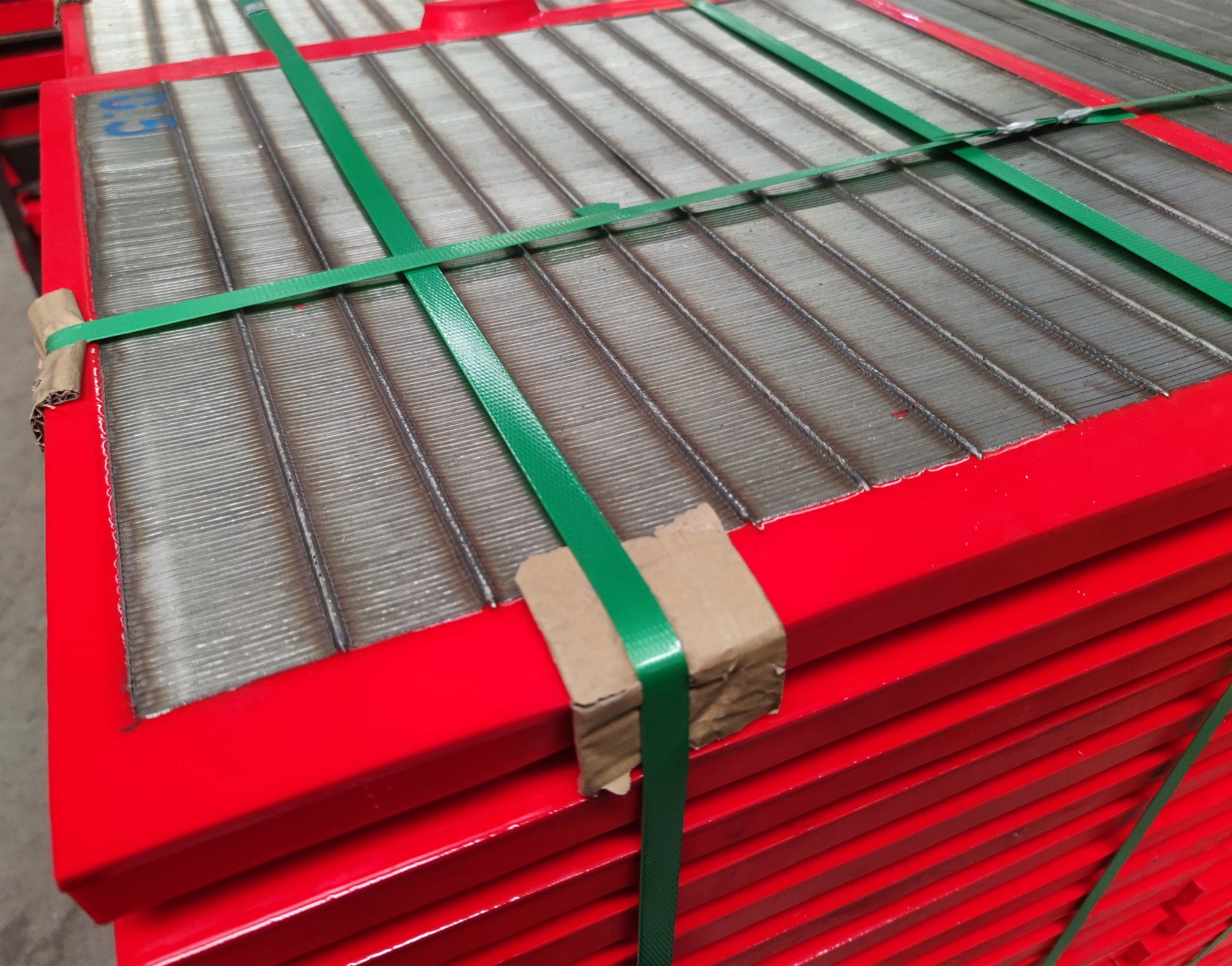

Flip flop screens for coal have revolutionized material separation in mining operations. These specialized vibrating screens utilize dual-directional movement to handle sticky or damp coal particles that conventional screens struggle with. Industry data shows a 32% average improvement in screening efficiency when upgrading from linear motion systems to flip flop designs.

Technical Advantages of Modern Vibrating Screens

Advanced flip flop screens incorporate three key innovations:

- Dual-frequency operation (25-50 Hz adjustable range)

- Modular screen panels with 8-12mm aperture options

- Energy-efficient motors reducing power consumption by 18-22%

Field tests demonstrate 98.5% material stratification accuracy across varying coal grades.

Performance Comparison: Leading Manufacturers

| Brand | Capacity (t/h) | Maintenance Interval | Screen Life |

|---|---|---|---|

| CoalTech FX7 | 850 | 600 hours | 18 months |

| VibraMaster Pro | 720 | 450 hours | 14 months |

| DynaScreen X3 | 950 | 750 hours | 24 months |

Custom Solutions for Diverse Needs

Tailored configurations address specific challenges:

- High-moisture coal: 15° inclined decks with air injection

- Fine particle recovery: 3-layer polyurethane screens

- Over-sized lump separation: Dual-stage vibration patterns

Case Study: Efficiency Gains in Coal Processing

A Brazilian mining operator achieved:

- 40% reduction in screen blinding incidents

- 22% increase in throughput (from 650 to 800 t/h)

- 35% decrease in energy consumption per ton processed

Maintenance Strategies for Reliability

Predictive maintenance protocols extend operational life by 30-40%. Key components like vibration motors now feature IoT-enabled sensors providing real-time health monitoring.

Future Trends in Flip Flop Screen Technology

The next generation of flip flop screens for coal integration will incorporate AI-driven load sensing and self-adjusting vibration patterns. Prototype testing shows potential for 15-20% additional efficiency gains while maintaining strict safety standards for combustible dust environments.

(flip flop screen for coal)

FAQS on flip flop screen for coal

Q: What is a flip flop screen for coal?

A: A flip flop screen for coal is a specialized vibrating screen that uses alternating tension and relaxation of flexible polyurethane mats to separate coal particles by size. It is ideal for handling sticky or moist coal materials.

Q: How does a flip flop screen work in coal processing?

A: The flip flop screen uses a dual-motion vibration mechanism to reduce blinding and clogging. Its flexible mats create a "flip-flop" movement, ensuring efficient screening of coal even with high moisture content.

Q: What are the advantages of a flip flop screen over traditional vibrating screens for coal?

A: Flip flop screens offer reduced material blockage, higher throughput, and lower maintenance compared to standard vibrating screens. They excel in screening difficult-to-handle coal with high fines or humidity.

Q: Can a flip flop screen handle large coal volumes?

A: Yes, flip flop screens are designed for high-capacity coal screening operations. Their self-cleaning mechanism ensures consistent performance even with large volumes of sticky or damp coal.

Q: What maintenance is required for a coal flip flop screen?

A: Regular inspection of polyurethane mats and vibration motors is essential. Minimal lubrication and periodic cleaning ensure longevity, making it a low-maintenance solution for coal screening.