Polyurethane sieve plate has the advantages of light weight, high screening efficiency, not easy to plug holes, wear resistance, impact resistance, long life and so on. Has been widely used in coal, mining, metallurgy and other industries on the vibrating screen.

As one of the main parts of screening and sorting equipment, polyurethane screen plate is also one of the wearing parts. High-quality screen plate, very wear-resistant, corrosion resistance, long service life, we share with you how to choose high-quality polyurethane screen plate.

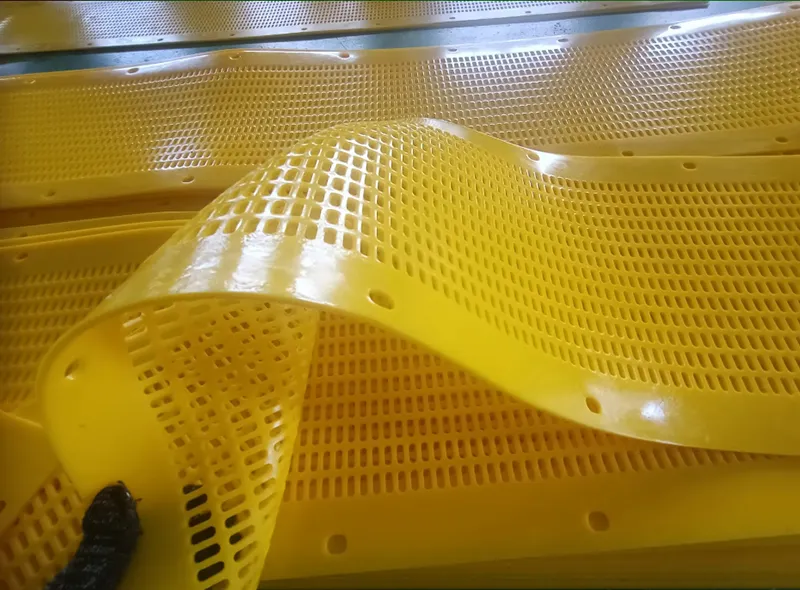

1.Good polyurethane screen appearance is smooth, screen hole gap is uniform; Pure color; Neat margins; The edge of the wrapped screen is uniform.

2.The screen surface should be smooth and not rough; Use the foot to see the collapse of the screen surface, a good polyurethane screen should have strong elasticity and patience, and the screen is moderate.

3.The more the number of sieving holes, the higher the opening rate, the higher the screening efficiency and yield.

4.Pay attention to the connection, that is, the connecting head between the screen and the screen during installation, and the connecting head will directly affect the screening efficiency.

In short, it is very important to choose a high-quality polyurethane screen plate, because it is not only related to the effect of equipment screening materials, but also has a great impact on the economic benefits of users.