1.Determine the characteristics of the screening material

First, you need to determine the characteristics of the material to be screened, including the particle size, hardness, shape and water content of the material. These factors will directly affect the screening effect and the life of the sieve plate. For example, for materials with finer particle size and higher moisture content, it is necessary to select a sieve plate with smaller pore size and softer material; For materials with larger particle size and higher hardness, it is necessary to select a screen plate with larger aperture and harder material.

Determine screening efficiency requirements

2.Determine screening efficiency requirements

Second, you need to determine the requirements for screening efficiency. Screening efficiency refers to the ratio of the amount of material that can be screened to the amount of feed per unit time. In general, the higher the screening efficiency, the higher the production efficiency. However, too high screening efficiency may lead to screen plate blockage or increased wear, affecting equipment life and production safety. Therefore, it is necessary to determine the appropriate screening efficiency according to the actual production needs and material characteristics.

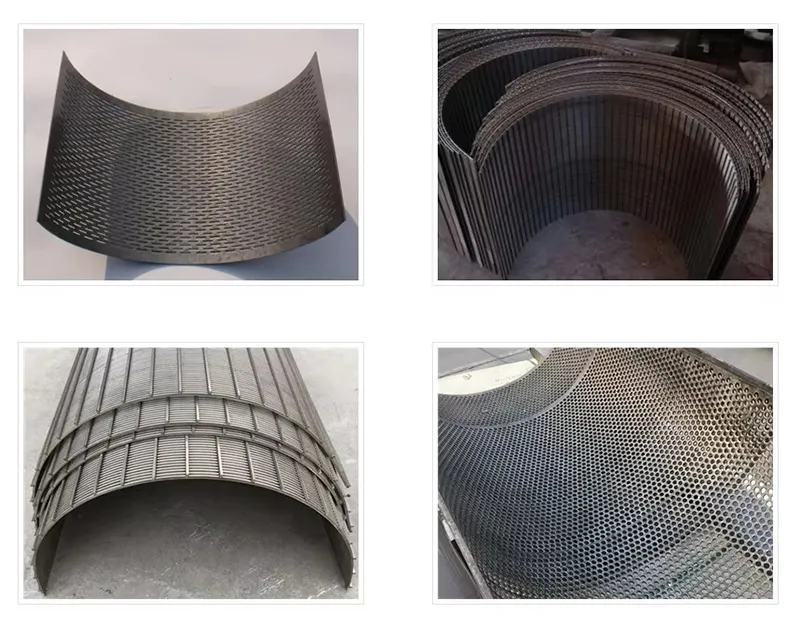

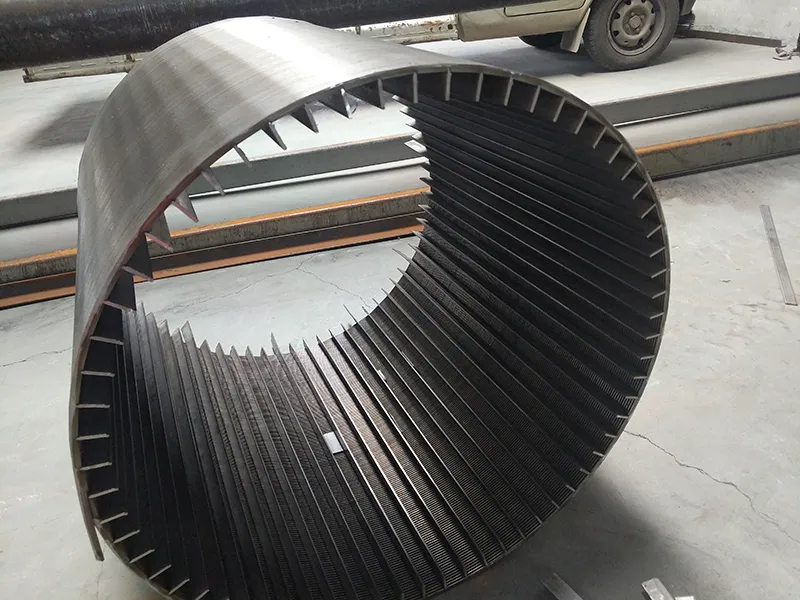

3.Select the appropriate sieve screen material and aperture

According to the material characteristics and screening efficiency requirements, you need to choose the appropriate sieve plate material and aperture. Stainless steel seam sieve plate is generally made of 304 or 316L material, which has good corrosion resistance and strength. For different application scenarios and material characteristics, it is necessary to select different aperture sieve plates. In general, the larger the aperture, the higher the screening efficiency, but the service life will be shortened accordingly; The smaller the aperture, the lower the screening efficiency, but the service life will be correspondingly extended. Therefore, the relationship between aperture size and production efficiency needs to be balanced according to actual demand.

4.Consider equipment size and budget

Finally, consider equipment size and budget. The size and price of stainless steel slotted sieve plates vary with factors such as model, material and aperture. In the selection, the equipment size and budget range need to be determined according to the actual production needs. At the same time, it is also necessary to consider the installation space and operation convenience of the equipment to ensure that the equipment can be successfully put into use and play the expected effect.