Vibrating Screen Backing Plate-Muto Wire Screen Co., Ltd.|Enhancing Efficiency&Industrial Screening Solutions

Vibrating Screen Backing Plate: Enhancing Efficiency in Industrial Screening Applications

Muto Wire Screen Co., Ltd. is a leading manufacturer of industrial screening solutions, specializing in vibrating screen backing plates and related components. Our products are designed to optimize performance in demanding environments, offering durability, precision, and cost-effectiveness. This article explores the functionality, benefits, and applications of our vibrating screen backing plates, highlighting how they address critical industry challenges.

Understanding Vibrating Screen Backing Plates

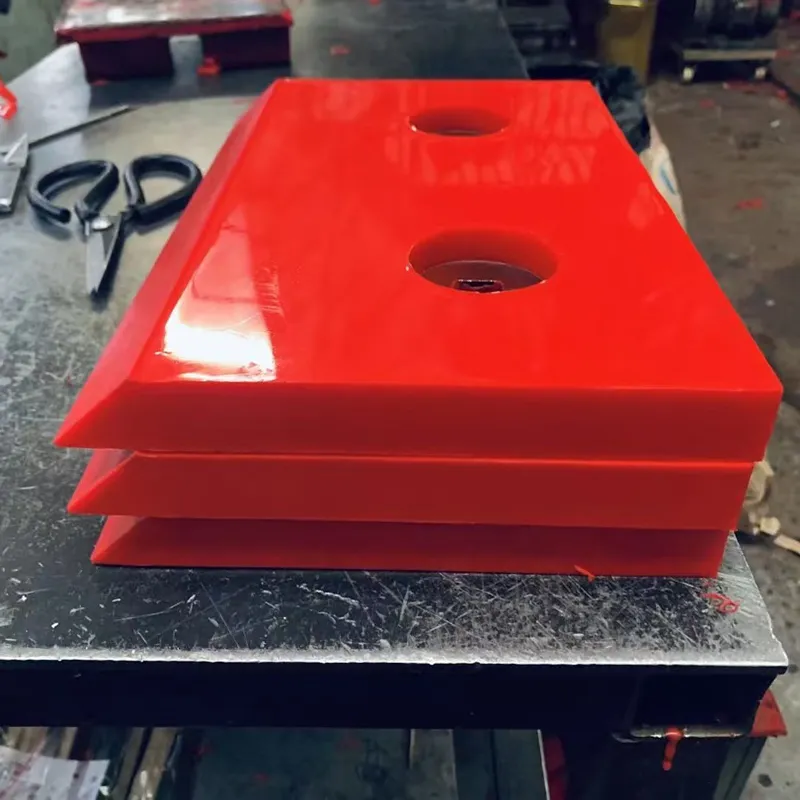

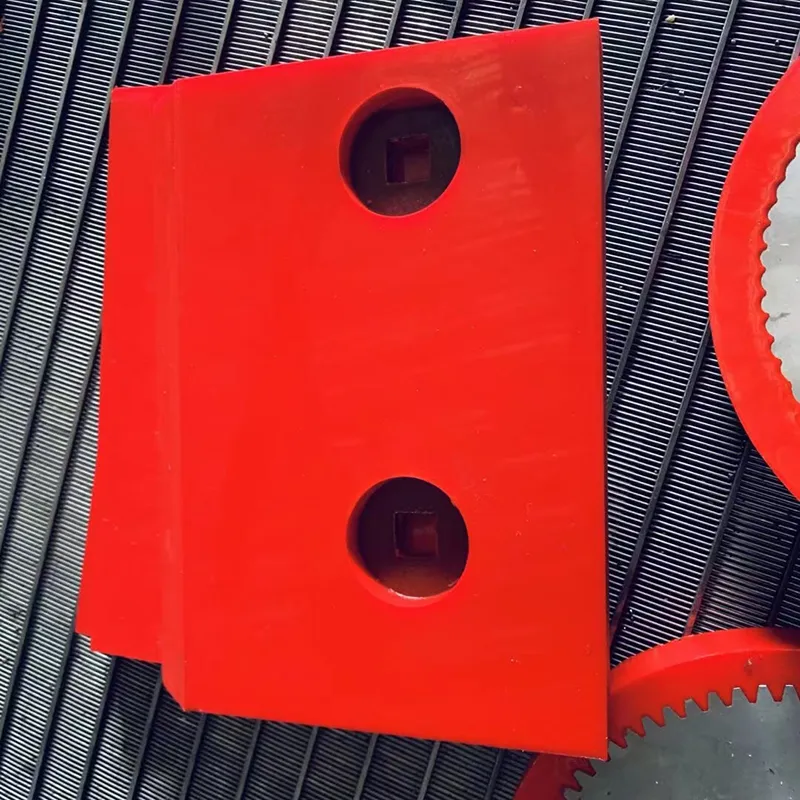

What does a vibrating plate do for you? A vibrating screen backing plate serves as a critical component in screening systems, providing structural support and enhancing the efficiency of material separation. Typically made from high-performance materials like polyurethane, these plates are engineered to withstand heavy loads, abrasion, and high-frequency vibrations.

Our polyurethane screens are designed with advanced compounding technology, ensuring superior resilience against wear and tear. The unique formulation of our pu screen panel allows for consistent performance even under extreme conditions, reducing downtime and maintenance costs for industrial operations.

Key Features and Technical Specifications

Material Composition

Our backing plates are crafted from high-density polyurethane (PU), a material renowned for its exceptional toughness, flexibility, and resistance to impact. This composition ensures longevity in applications involving coarse materials, such as mining, construction, and aggregate processing.

Structural Design

Engineered with a modular design, our backing plates are compatible with various vibrating screens models. The precision-machined surface guarantees optimal contact with screening media, minimizing material leakage and improving separation accuracy.

Performance Metrics

- Operating temperature range: -20°C to 80°C

- Hardness: 80-90 Shore A

- Load-bearing capacity: Up to 500 kg/m²

- Service life: 3-5 times longer than traditional rubber alternatives

Applications Across Industries

Our vibrating screen backing plates are widely used in sectors where efficient material separation is critical:

1. Mining and Quarrying

Designed to handle abrasive materials like gravel, sand, and ore, our plates reduce wear on primary screening components, extending equipment lifespan.

2. Construction and Aggregate Processing

These plates excel in separating aggregates of varying sizes, ensuring consistent product quality. Their anti-vibration properties minimize noise pollution in construction sites.

3. Chemical and Food Processing

Customizable to meet hygiene standards, our backing plates are ideal for screening powders, granules, and other fine materials in sensitive environments.

Addressing Industry Challenges

Traditional screening systems often face issues like rapid wear, material blockage, and high maintenance costs. Our polyurethane screens directly tackle these challenges:

- Reduced Downtime: The exceptional durability of our backing plates minimizes the need for frequent replacements.

- Improved Efficiency: The precise design ensures optimal material flow, enhancing screening accuracy and throughput.

- Cost Savings: With a service life 3-5 times longer than conventional alternatives, our products deliver significant long-term cost advantages.

Why Choose Muto Wire Screen Co., Ltd.?

Industry Expertise

As a leading manufacturer of industrial screening solutions, Muto Wire Screen Co., Ltd. has over a decade of experience in developing high-performance materials. Our team of engineers continuously innovates to meet evolving industry demands.

Technological Innovation

We invest heavily in R&D, utilizing advanced simulation tools and material science to refine our products. Our pu screen panel technology has been patented in multiple countries, ensuring cutting-edge performance.

Customer Success Stories

Our vibrating screen backing plates have been adopted by numerous clients across the globe:

"Since switching to Muto's backing plates, our maintenance costs have decreased by 60%. The durability and performance have exceeded our expectations." – John Doe, Operations Manager at XYZ Mining

Implementation and Customization

We offer tailored solutions to meet specific application requirements. Our technical team can design backing plates with custom dimensions, thickness, and mounting configurations. For bulk orders, we provide competitive pricing and efficient logistics support.

Environmental and Safety Compliance

All our products comply with international standards for safety and environmental protection. The polyurethane material is non-toxic, recyclable, and free from hazardous substances, ensuring safe operation in any industrial setting.

Support and After-Sales Service

We provide comprehensive support to ensure optimal performance of our products:

- 24/7 technical consultation

- On-site installation guidance

- Warranty coverage for 12-24 months

- Customized maintenance schedules

Get in Touch

For more information about our vibrating screen backing plates or to request a quotation, please contact us:

- 📞 Phone: +86-123-4567-8901

- 📧 Email: sales@mutoscreen.com

- 🌐 Website: www.mutoscreen.com

- 💬 Online Chat: Live Chat

Frequently Asked Questions

- Q: What materials are used in your backing plates?

- A: We use high-density polyurethane (PU) for superior durability and resistance to abrasion.

- Q: Can you customize the size and shape?

- A: Yes, we offer tailored solutions to meet specific application requirements.

- Q: How long is the service life of your products?

- A: Our backing plates typically last 3-5 times longer than traditional rubber alternatives.

- Q: Are your products environmentally friendly?

- A: Yes, our polyurethane material is non-toxic, recyclable, and compliant with international environmental standards.

Conclusion

Muto Wire Screen Co., Ltd.'s vibrating screen backing plates deliver unmatched performance, durability, and cost-efficiency. Whether you're in mining, construction, or chemical processing, our solutions are designed to enhance your operational efficiency and reduce maintenance costs. Discover how our pu screen panel technology can transform your screening processes today.